RUBIG Training

There are no seminars planned at the moment.

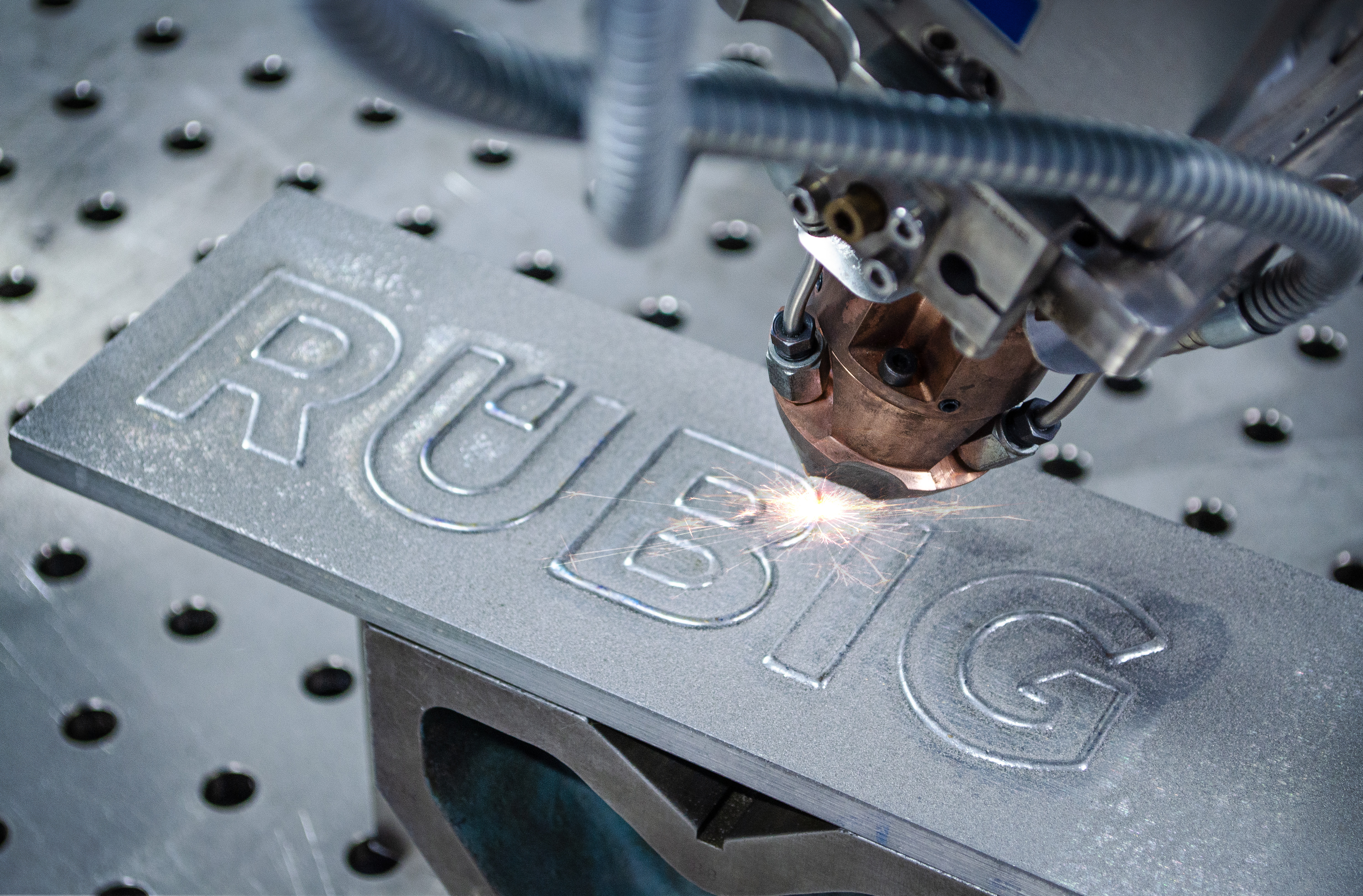

The RUBIG Group

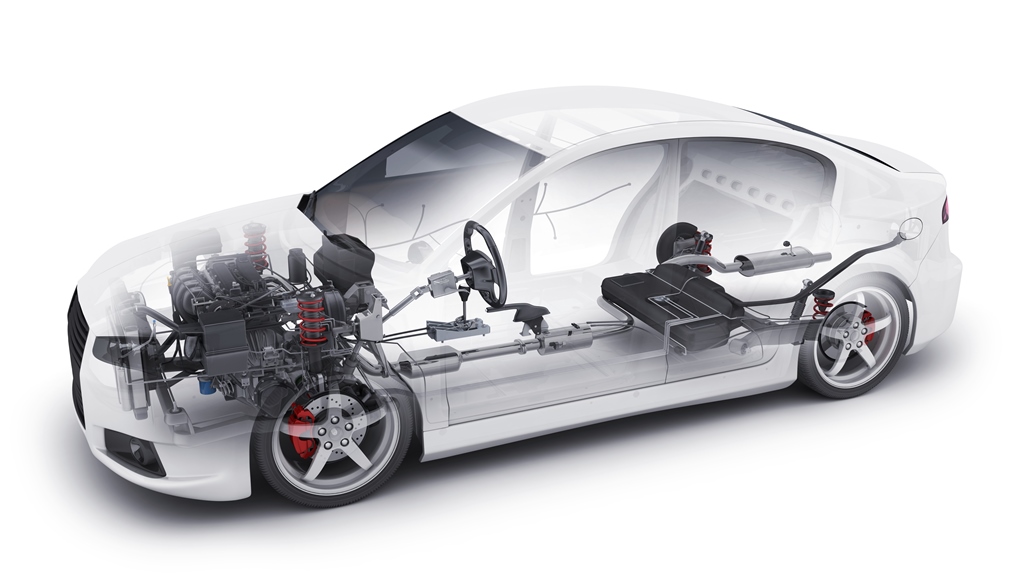

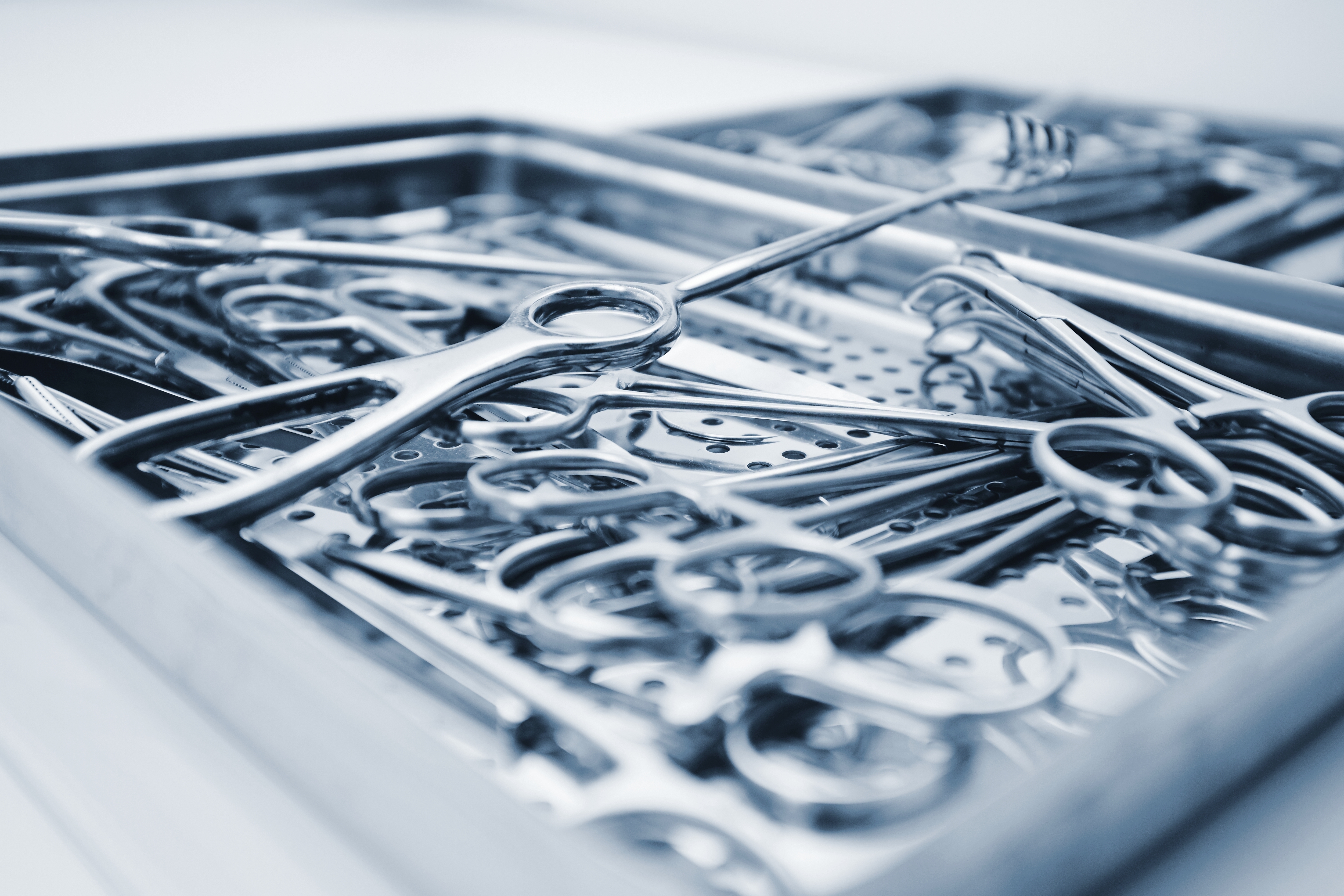

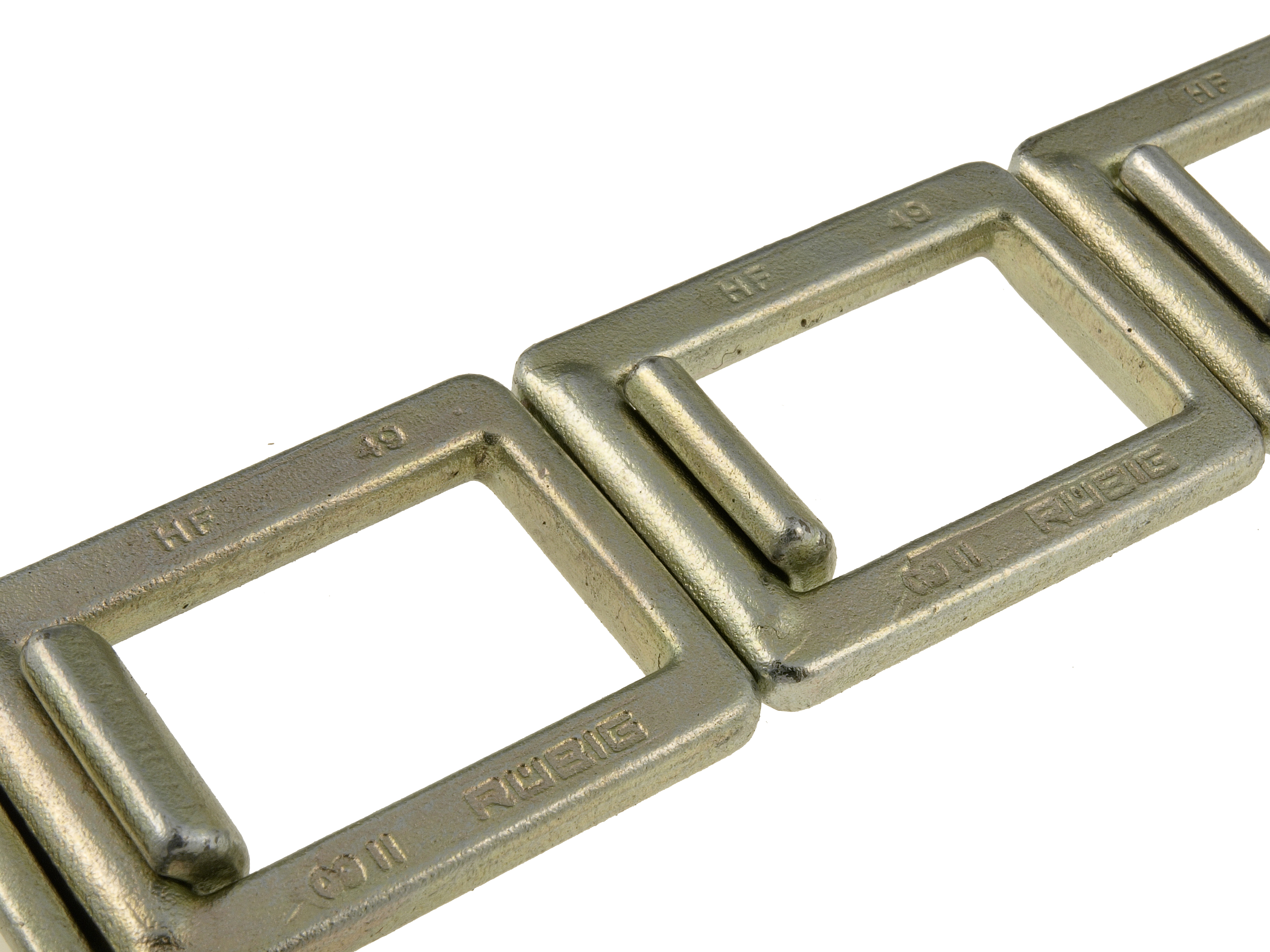

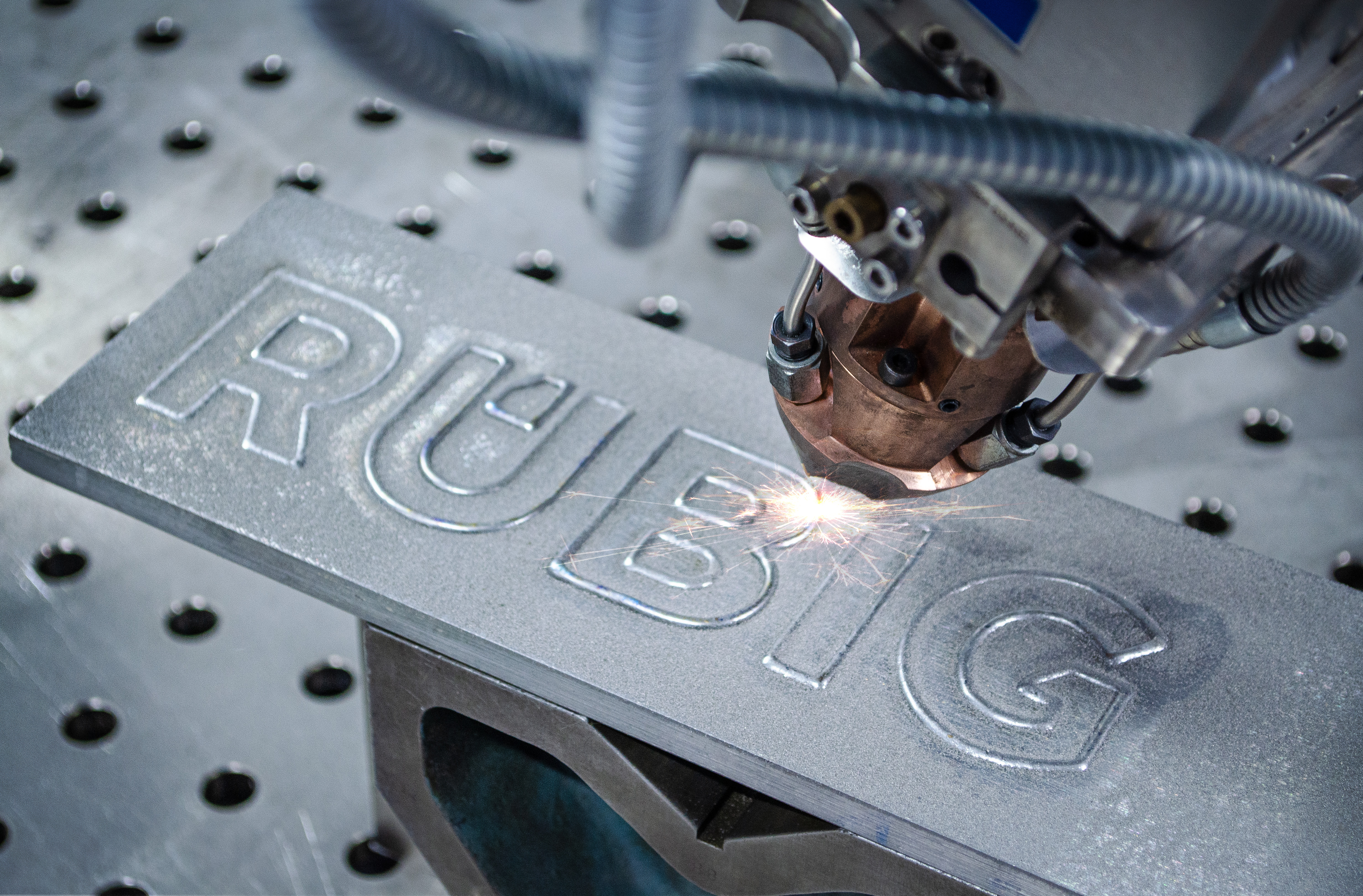

Since the foundation of RUBIG in 1946, the company has grown from a small drop forging company to a center of excellence for metal processing. The unique synergy potential resulting from the close cooperation between RUBIG Industrial Furnaces, Heat Treatment and Die Forge adds particular value for our customers.