Anlagentechnik

Anlagentechnik

Standorte

RÜBIG Anlagentechnik

RÜBIG Anlagentechnik

RÜBIG Kunden profitieren von mehr als 20 Jahren Entwicklungserfahrung im Bereich maßgeschneiderter Wärmebehandlungsanlagen für verschiedenste Branchen.

Produkte

Plasmanitrieranlage - MICROPULS® Everest

Plasmanitrieranlage - MICROPULS® Everest

DLC Beschichtungsanlage - MICROPULS® Diamond Xtended

DLC Beschichtungsanlage - MICROPULS® Diamond Xtended

Beschichtungsanlage - MICROPULS® Procoat

Beschichtungsanlage - MICROPULS® Procoat

PVD Beschichtungsanlage - MICROPULS® Lotus

PVD Beschichtungsanlage - MICROPULS® Lotus

Plasmagenerator

Plasmagenerator

Der RÜBIG Plasmagenerator ist das Herzstück jeder Anlage in der RÜBIG MICROPULS® Serie und generiert, wie der Name indiziert, Plasma. Der Generator nimmt dabei die Funktionen eines Spannungsumformers, auch Inverter genannt, wahr. Das heißt er wandelt gewöhnliche 400 V AC Dreiphasen Wechselspannung, sprich Kraft- oder Drehstrom, in galvanisch getrennte, rechteckförmig gepulste Gleichspannung um.

RÜBIG Generatoren zeichnen sich neben ihrer zuverlässigen, energieeffizienten Leistung auch durch ihre Modularität aus. Durch ihr kompaktes Design können sie rasch in bestehende Fertigungslinien integriert werden. Auch Upgrades zu einem späteren Zeitpunkt stellen kein Problem dar.

Gasnitrieranlage - GASCON K2

Gasnitrieranlage - GASCON K2

Härtetechnik

Härtetechnik

RÜBIG Härtetechnik

RÜBIG Härtetechnik

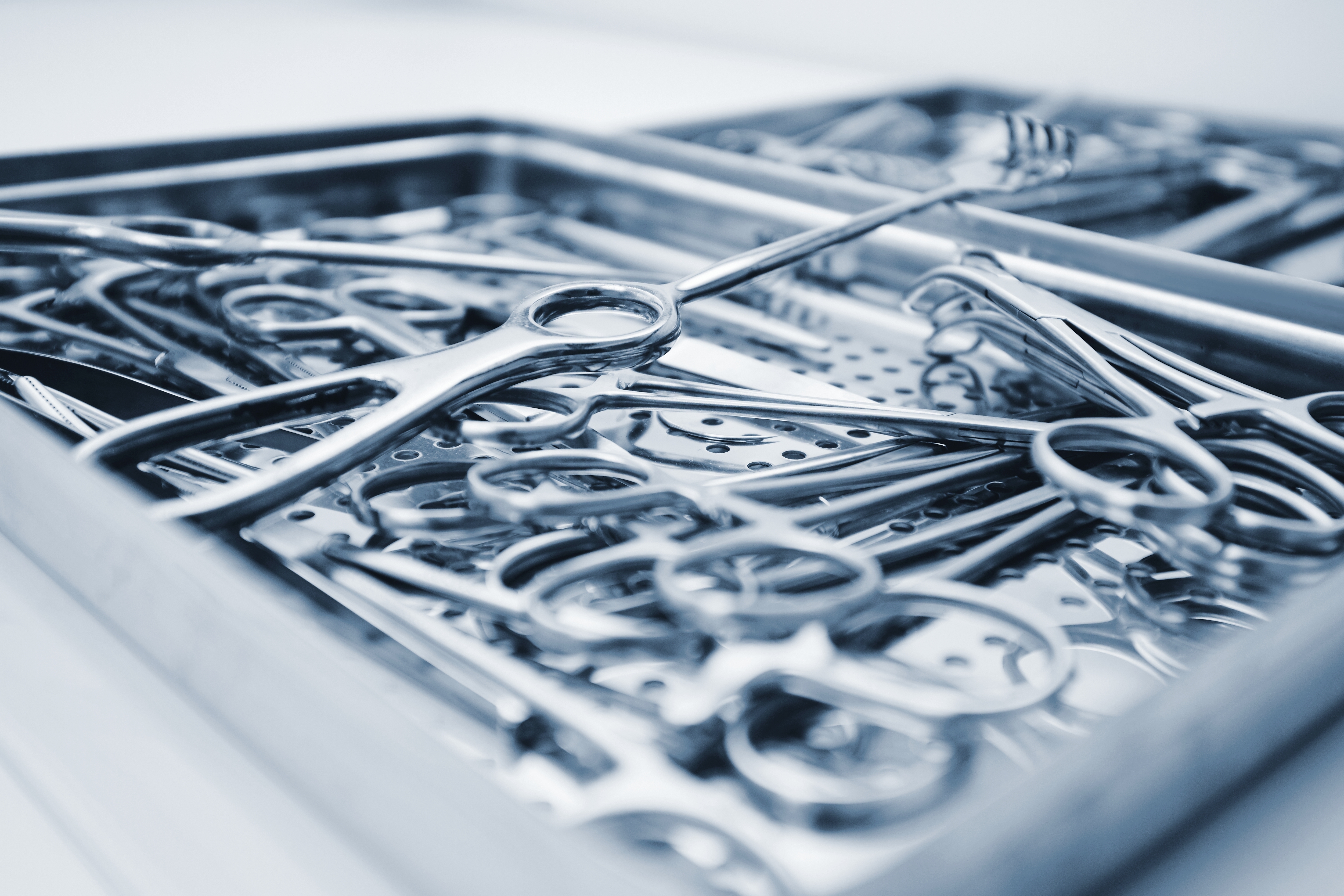

Verfahren

Plasmanitrieren - PLASNIT®

Plasmanitrieren - PLASNIT®

Hartstoffbeschichten - PLASTIT®

Hartstoffbeschichten - PLASTIT®

Vakuumhärten - R.VAC+®

Vakuumhärten - R.VAC+®

Einsatzhärten - R.CARB+®

Einsatzhärten - R.CARB+®

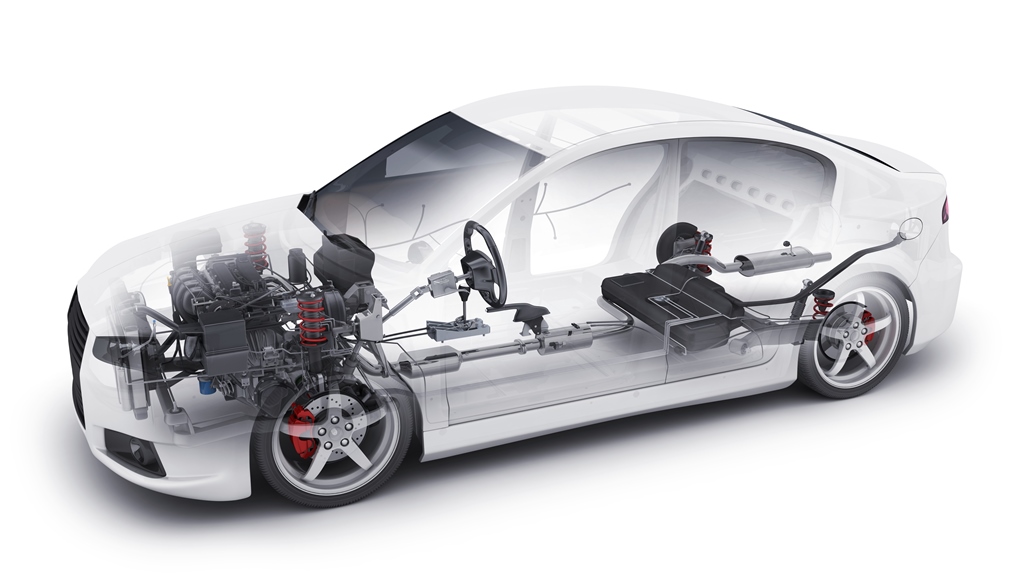

Branchen

Aluminium

Aluminium

RÜBIG ALU - Aluminium Wärmebehandlung

RÜBIG ALU - Aluminium Wärmebehandlung

Wir bieten verschiedene Aluminium Zustände an, wie z.B. T4, T5, T6, T7 mit Abschreckmöglichkeiten wie Luftabschreckung, Polymerabschreckung, Wasserabschreckung.

Schmiedetechnik

Schmiedetechnik

Schmiedetechnik

RÜBIG Schmiedetechnik

RÜBIG Schmiedetechnik

Seit 70 Jahren entwickelt die RÜBIG Schmiedetechnik zusammen mit Kunden innovative Lösungen vom Rohteil bis hin zum einbaufertigen Serienteil.

Produkte & Dienstleistungen

Schmiedeteile

Schmiedeteile

Die RÜBIG Schmiedetechnik erledigt durch jahrelange Erfahrung die Gestaltung und Überleitung von der Entwurfszeichnung zum Gesenkschmiedeteil.

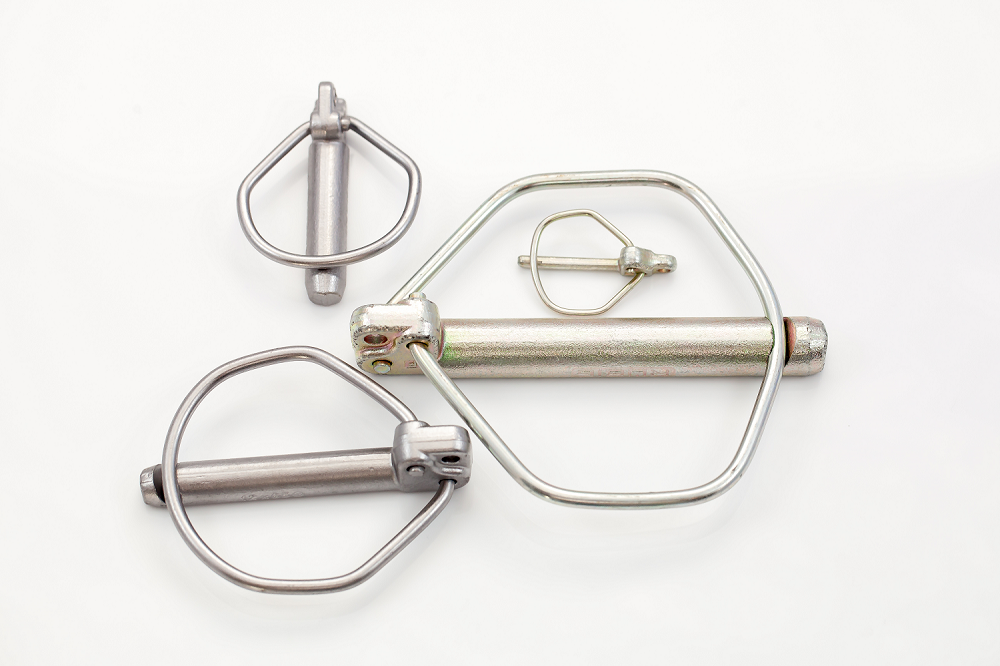

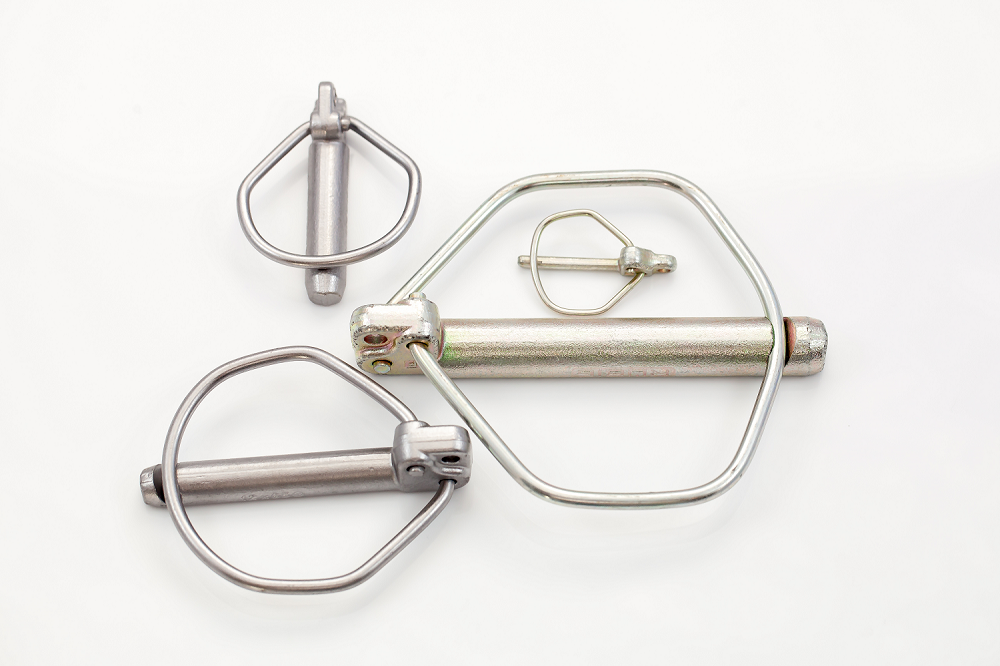

Befestigungstechnik

Befestigungstechnik

Die speziell entwickelte Form des Verschlussbügels garantiert die RÜBIG Schmiedetechnik höchste Schließkraft und Sicherheit der Klappstecker.

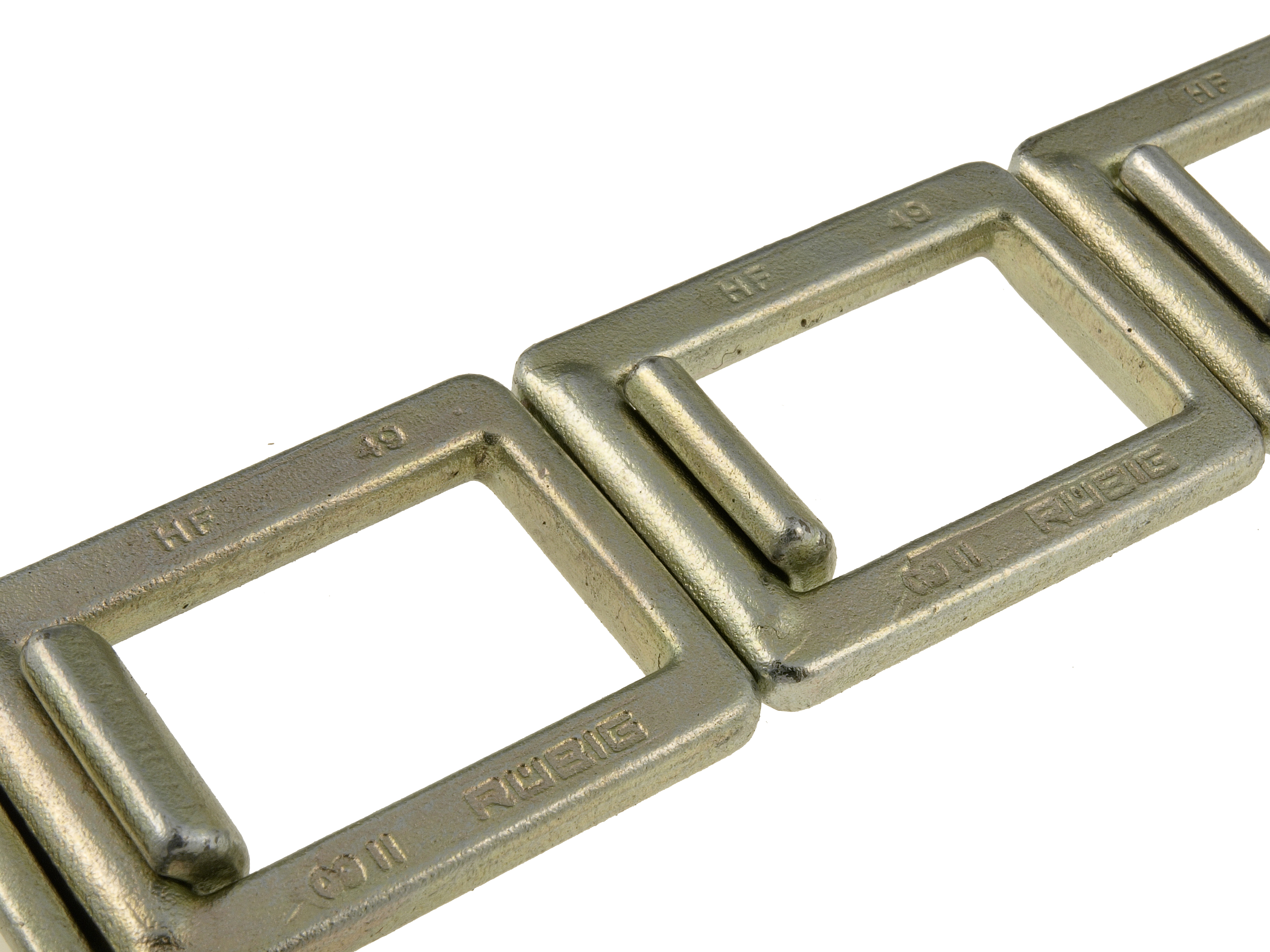

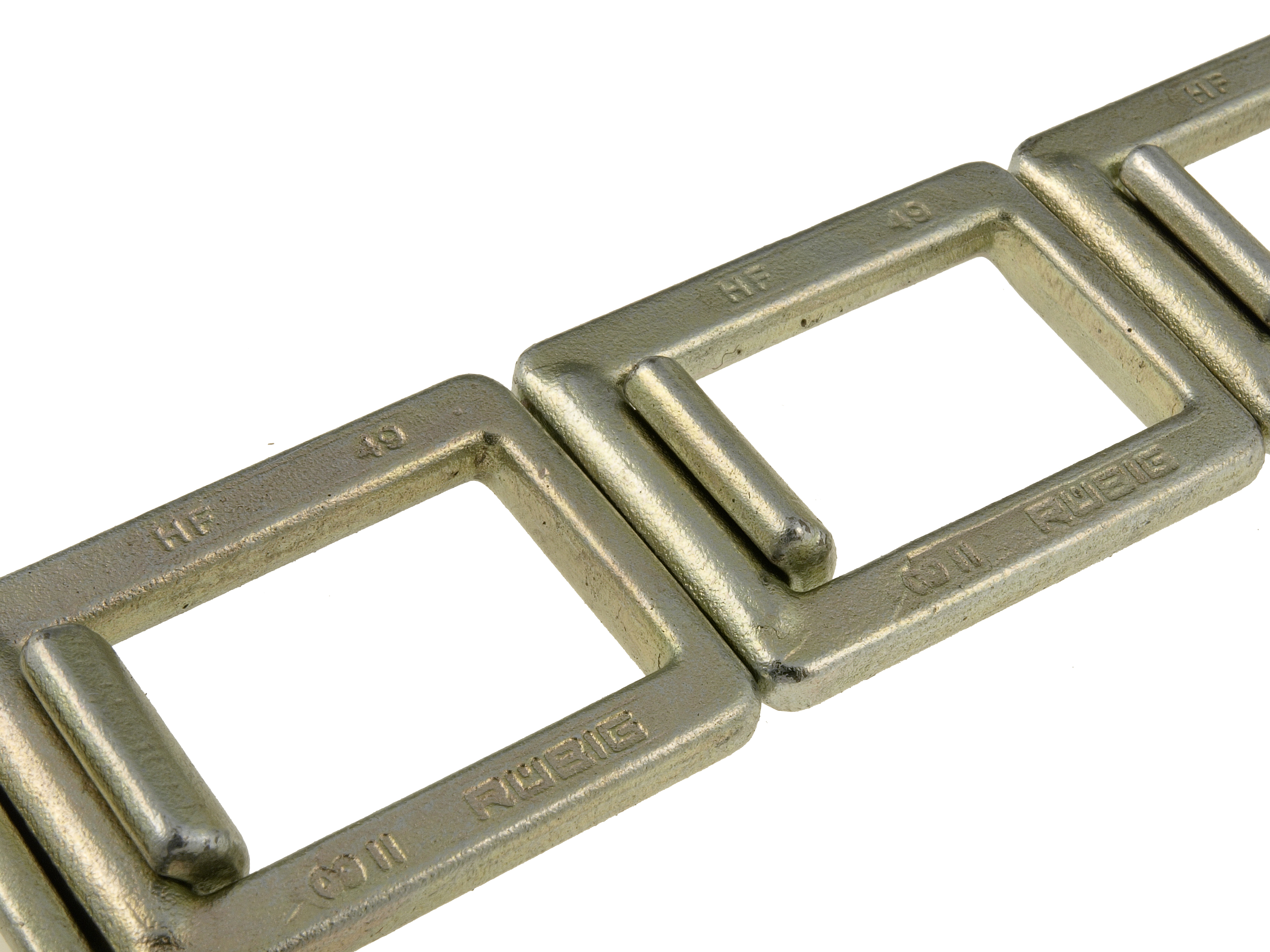

Antriebs- und Fördertechnik

Antriebs- und Fördertechnik

Die von RÜBIG gesenkgeschmiedeten und zerlegbaren Ketten zeichnen sich vor allem durch Verschleißbeständigkeit, Härte und Zähigkeit aus.

Freizeitprodukte

Freizeitprodukte

RÜBIG bietet fertigte Jagdmesser auf Wunsch mit Gravur oder Monogramm, präzise Messerschleifer und umweltfreundliches Anglerzubehör aus Stahl an.

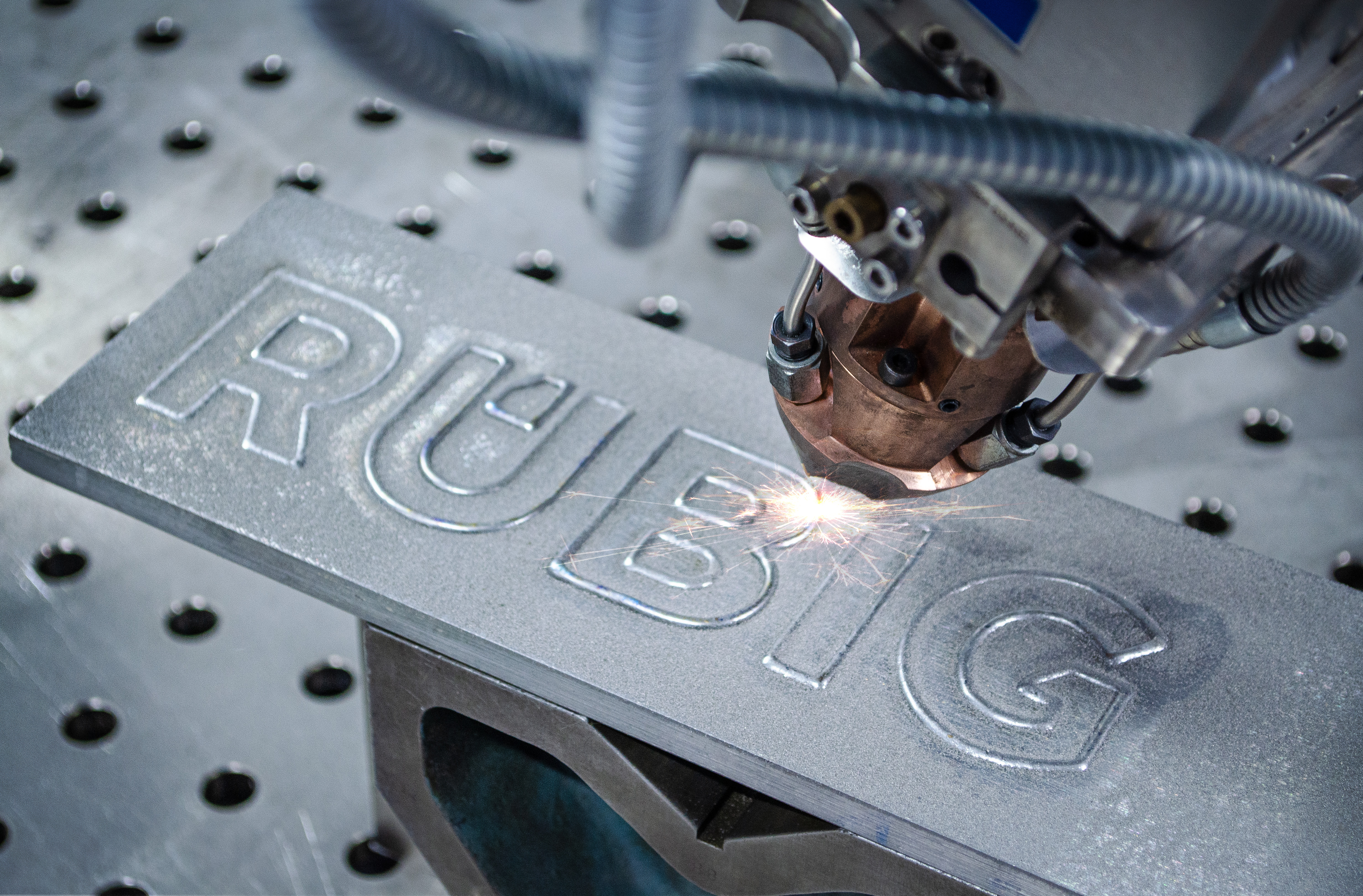

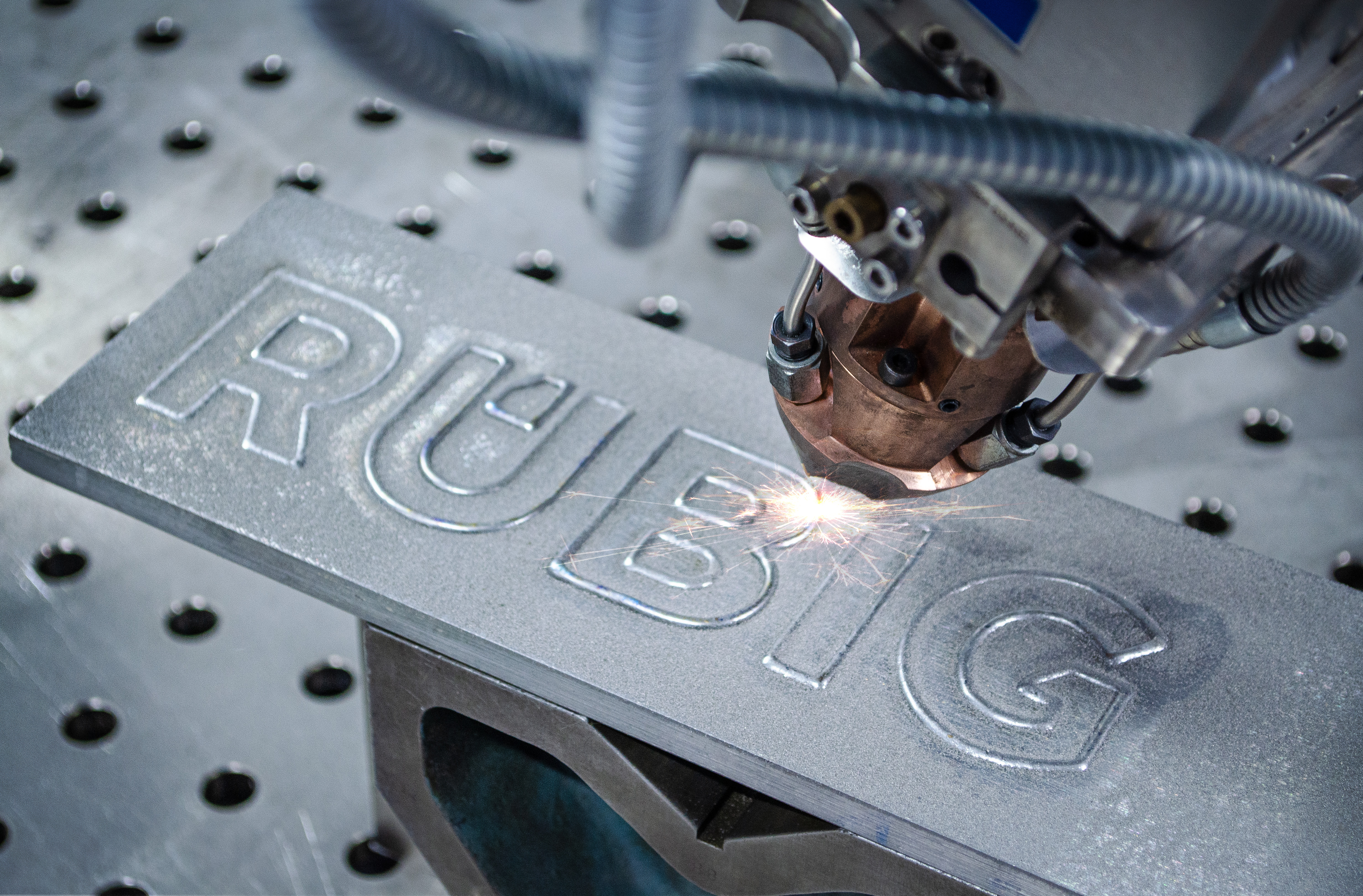

Zerspanungstechnik

Zerspanungstechnik

Die Möglichkeiten der von RÜBIG umfassen das Drehen, Bohren, Fräsen, Verzahnen, Schleifen sowie die automatische Werkstückvermessung.

Dienstleistungen

Dienstleistungen

RÜBIG bietet: Sandstrahlen, Schweißtechnik, Vergüten, Gleitschleifen, Fluxen und Pressarbeiten. Erfahren Sie mehr über unser Leistungsangebot!

Downloads

2D/3D Datendownload

2D/3D Datendownload

Hier können Sie 2D und 3D Daten von unseren Klappsteckern und Kettensystemen für Ihre Konstruktionszeichnungen herunterladen!

Technologie

Technologie

Competence Center

Competence Center

Forschung und Entwicklung

Forschung und Entwicklung

Wir stellen unser profundes Know-how zur Verfügung, um Ihre Bauteile zu optimieren oder weiterzuentwickeln. Erfahren Sie hier mehr!

Werkstoffuntersuchungen

Werkstoffuntersuchungen

Material- und Schadensanalysen, Härteprüfungen, Gefügebeurteilungen, Restaustenitbestimmungen, Eigenspannungsmessungen, Korrosionsuntersuchungen.

Seminare und Schulungen

Seminare und Schulungen

Vermittelt wird Wissen aus dem Gebiet der Wärmebehandlung - die Seminare richten sich speziell an Konstrukteure, Fertiger und Arbeitsvorbereiter.

Unternehmen

Unternehmen

Unternehmensgruppe RÜBIG

Daten und Fakten

Daten und Fakten

Hier finden Sie die Daten und Fakten zur Unternehmensgruppe RÜBIG.

Karriere

Karriere

Sie sind auf der Suche nach einem TOP-Arbeitgeber? Infomieren Sie sich hier über die offenen Stellen der RÜBIG Gruppe.

Unternehmensvideos

Unternehmensvideos

Durch unsere Unternehmensvideos erhalten Sie einen direkten Einblick in den Produktionsablauf unserer Standorte. Klicken Sie hier!

Support

404-Fehlerseite

404 - Seite nicht gefunden

Die von Ihnen aufgerufene Seite existiert nicht (mehr).

Hier gelangen Sie zur Startseite von rubig.com

RÜBIG GmbH & Co KG

Griesmühlstraße 4, 4600 Wels, AUSTRIA

Kontakt

Tel.: +43 (0) 7242 / 66060 ● Fax: DW-3077

E-Mail: ht.office[at]rubig[dot]com

© 2024 RÜBIG Österreich