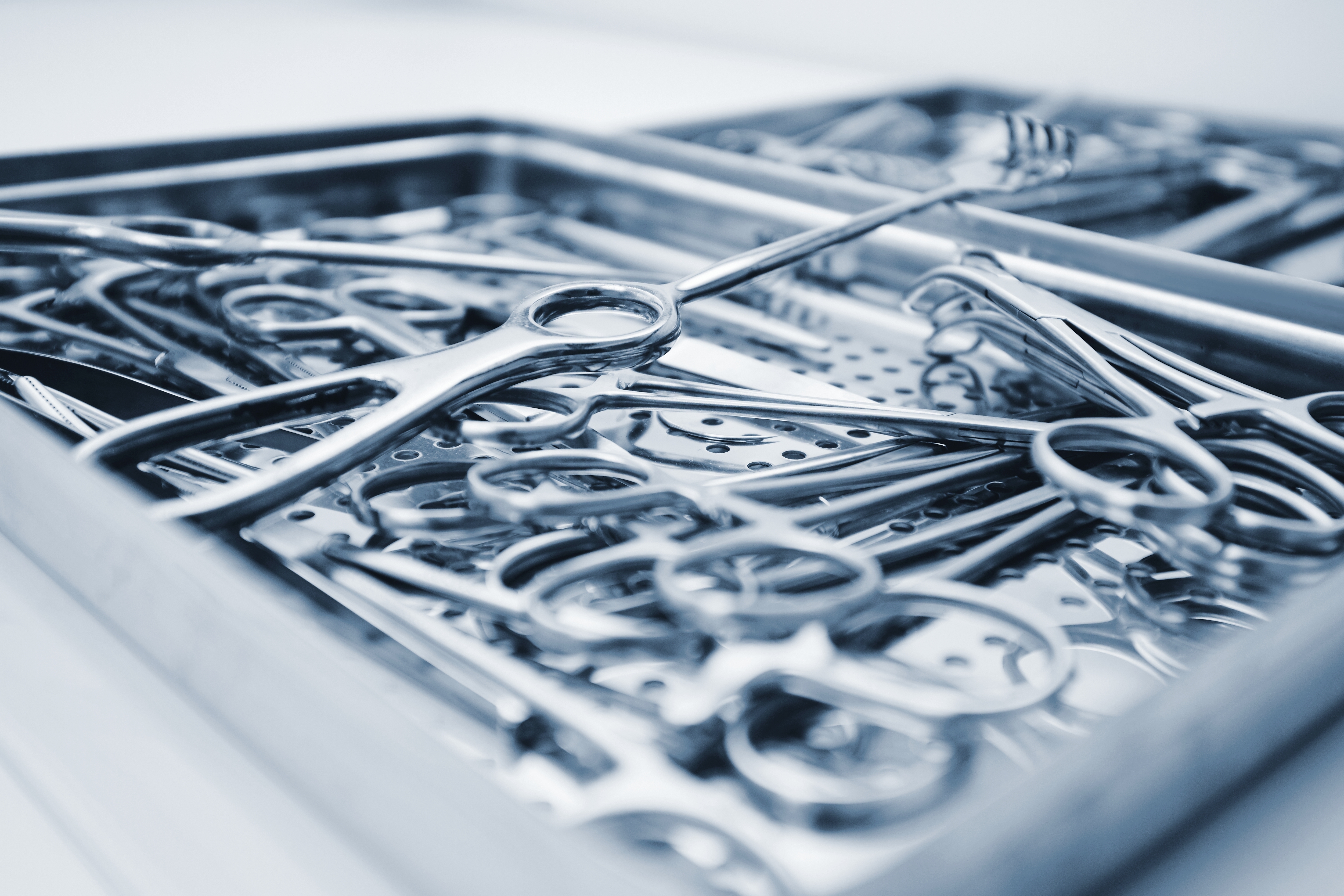

RUBIG is currently working in several research projects focusing on the biocidal coatings. The aim of the development work is to reduce or prevent the risk of infection through smear and droplet infections. In one of these projects, RUBIG works with partners to address the question of the antiviral and antibacterial efficacy and durability of copper-based coatings. Related regulatory and legal framework conditions are evaluated in the course of joint research activities, and RUBIG is happy to handle any resulting measures.

You find our curiosity about biocidal coating systems contagious? Contact us for more information!