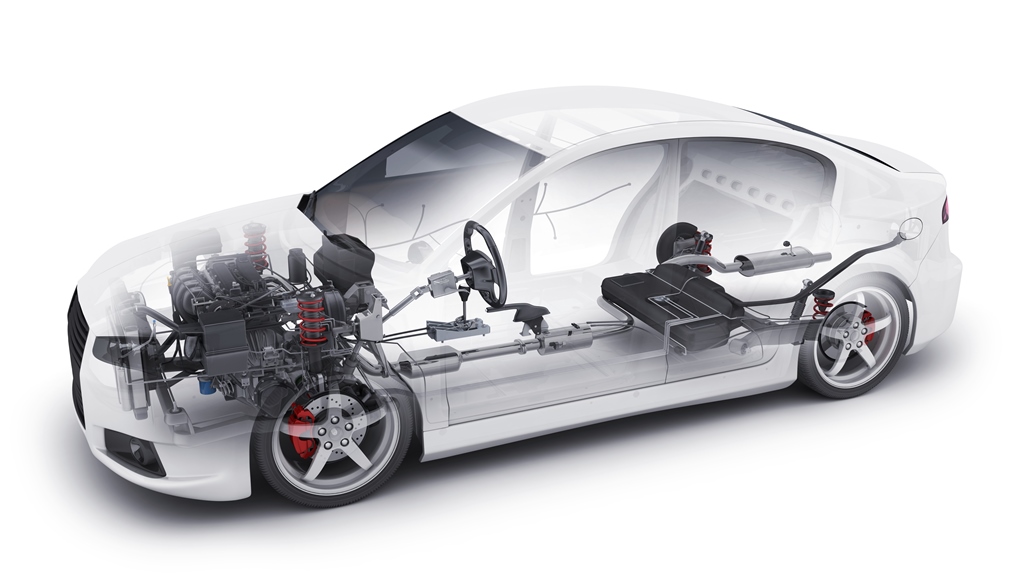

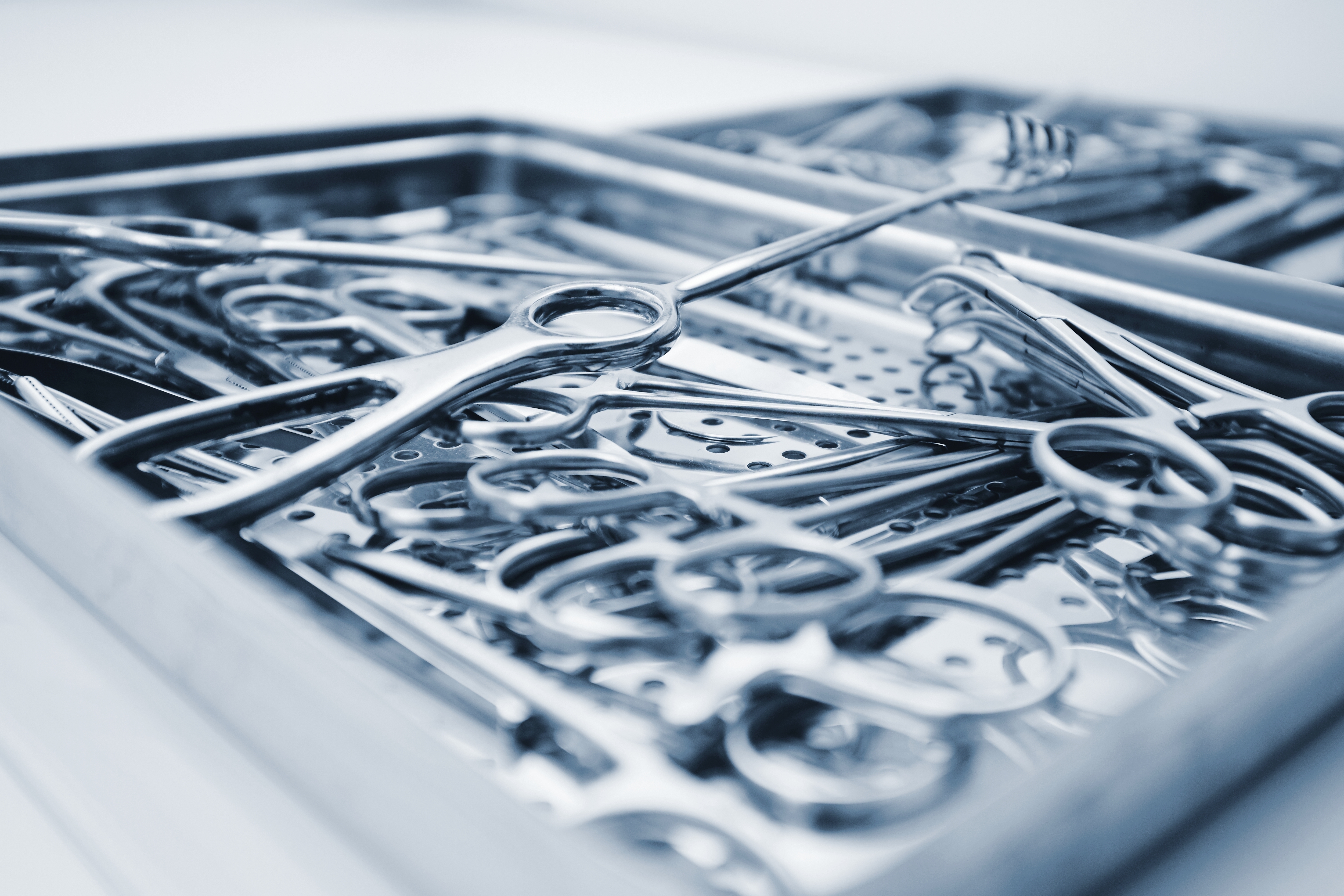

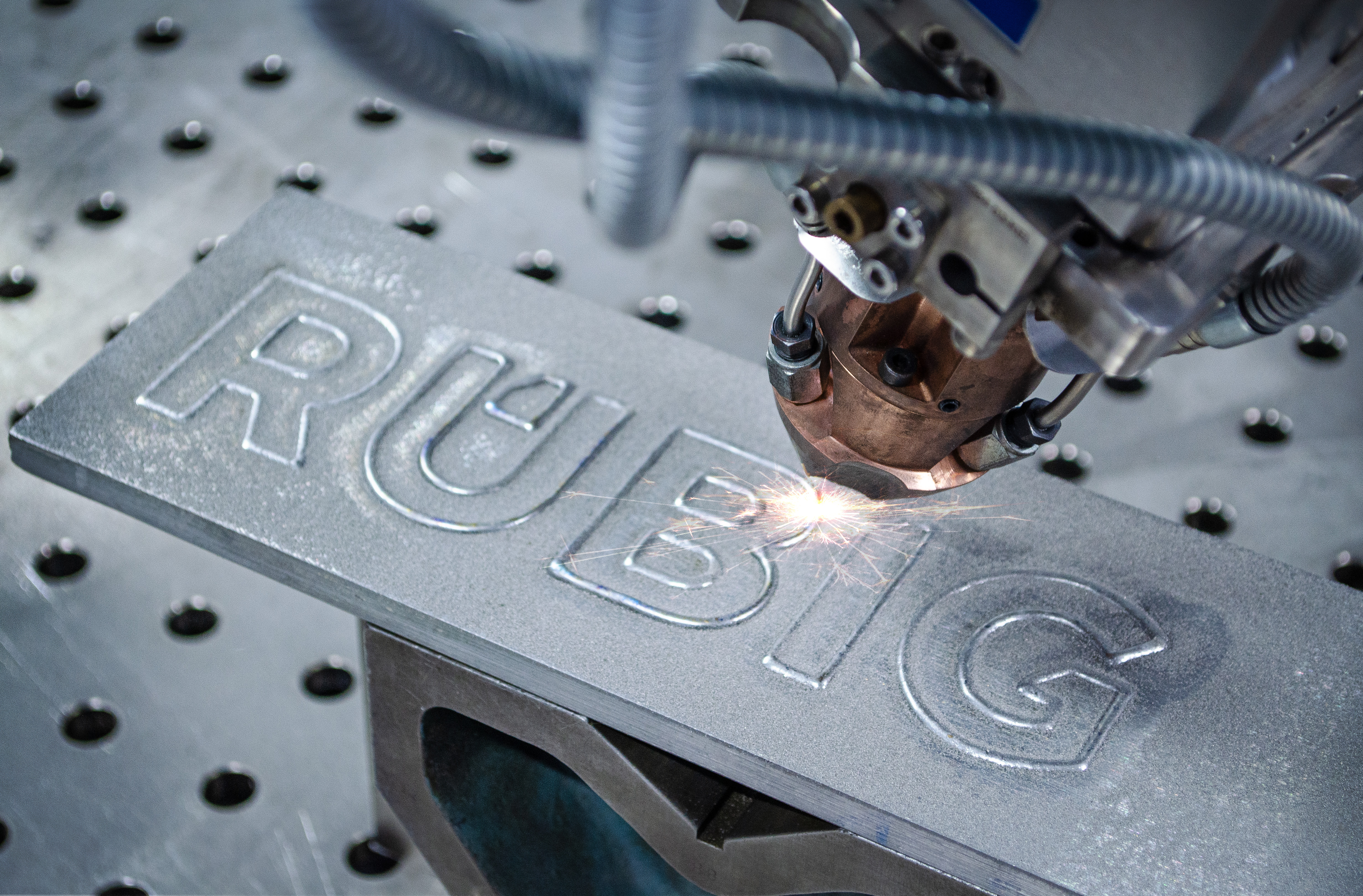

Different corrosion mechanisms can appear both on an individual basis and in combination. To deduce suitable prevention measures, it is important to identify the corrosion mechanism present. For this, profound knowledge of material engineering, metallurgy, chemistry – espe-cially corrosion science – production engineering as well as suitable laboratory equipment are necessary. RUBIG Competence Center, or RCC for short, possesses the crucial expertise and the testing means to characterize and solve cases of corrosive damage and to optimize components in order to prevent corrosive damage.

Different kinds of corrosion tests are carried out in the in-house materials laboratory:

- Neutral salt spray test

- Evacuation tests

- Current density/potential measurements

- Impedance spectroscopy

- Galvanic corrosion tests

- Stress corrosion cracking tests

Click here to learn more about RCC's corrosion testing!