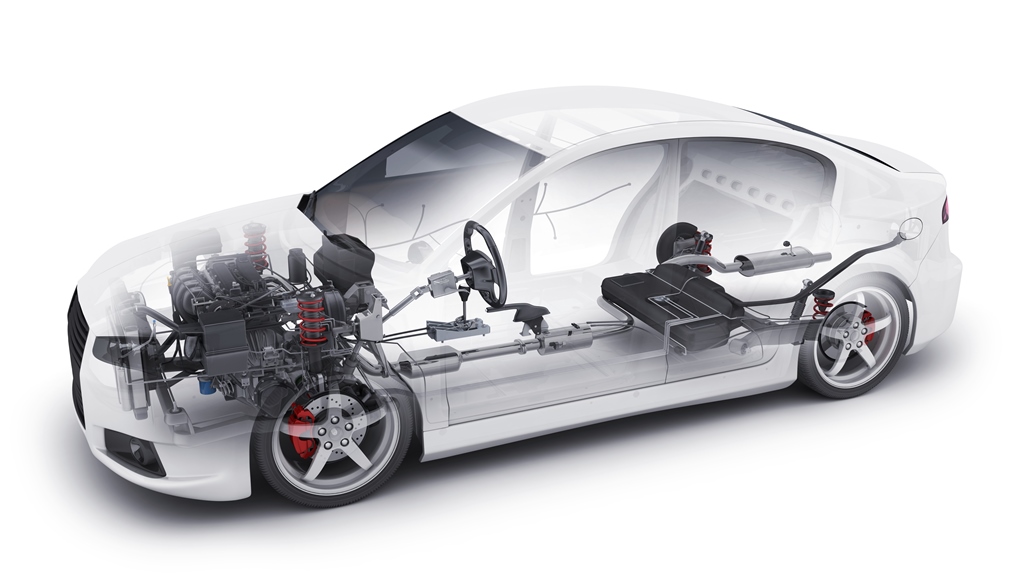

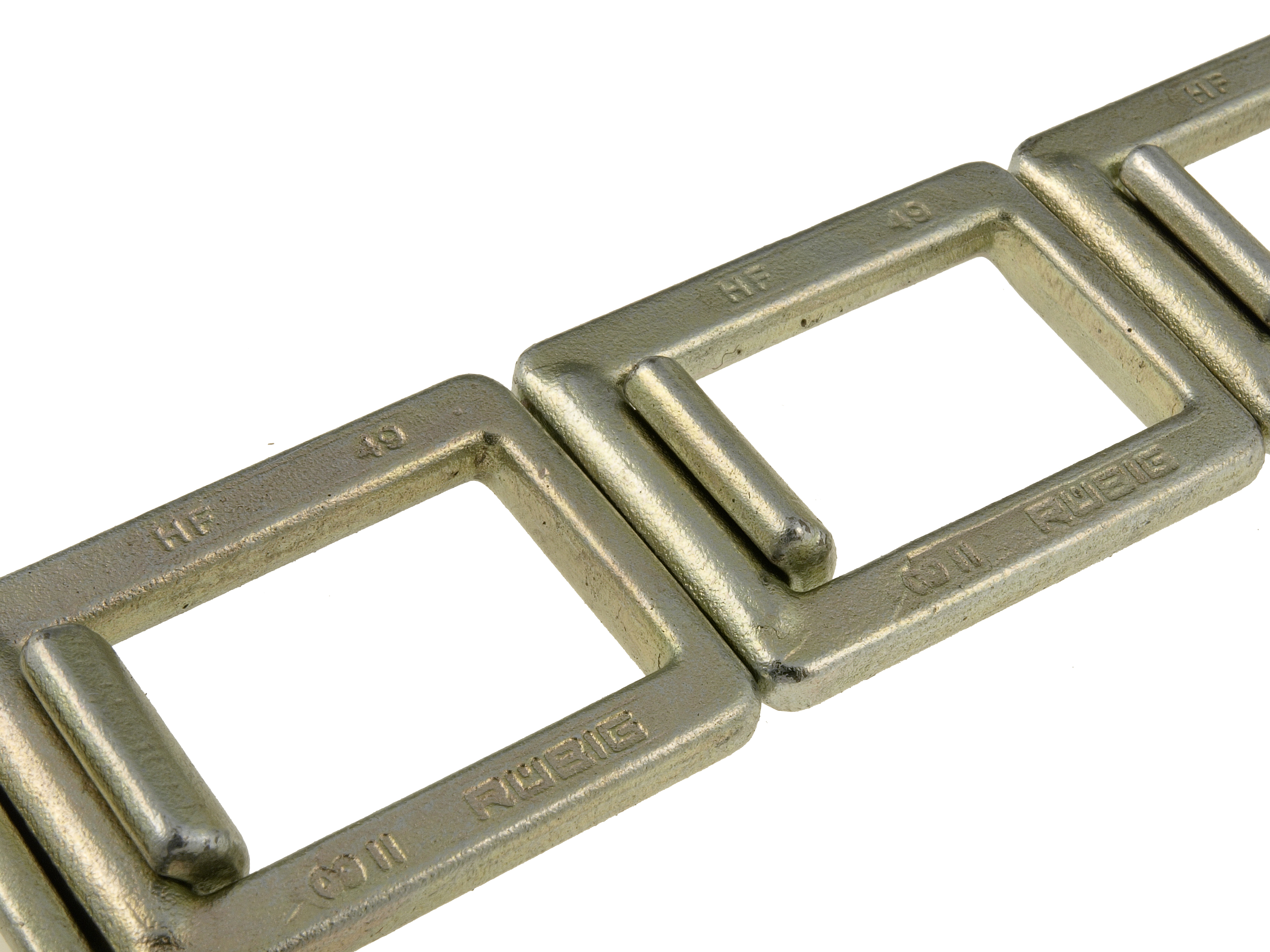

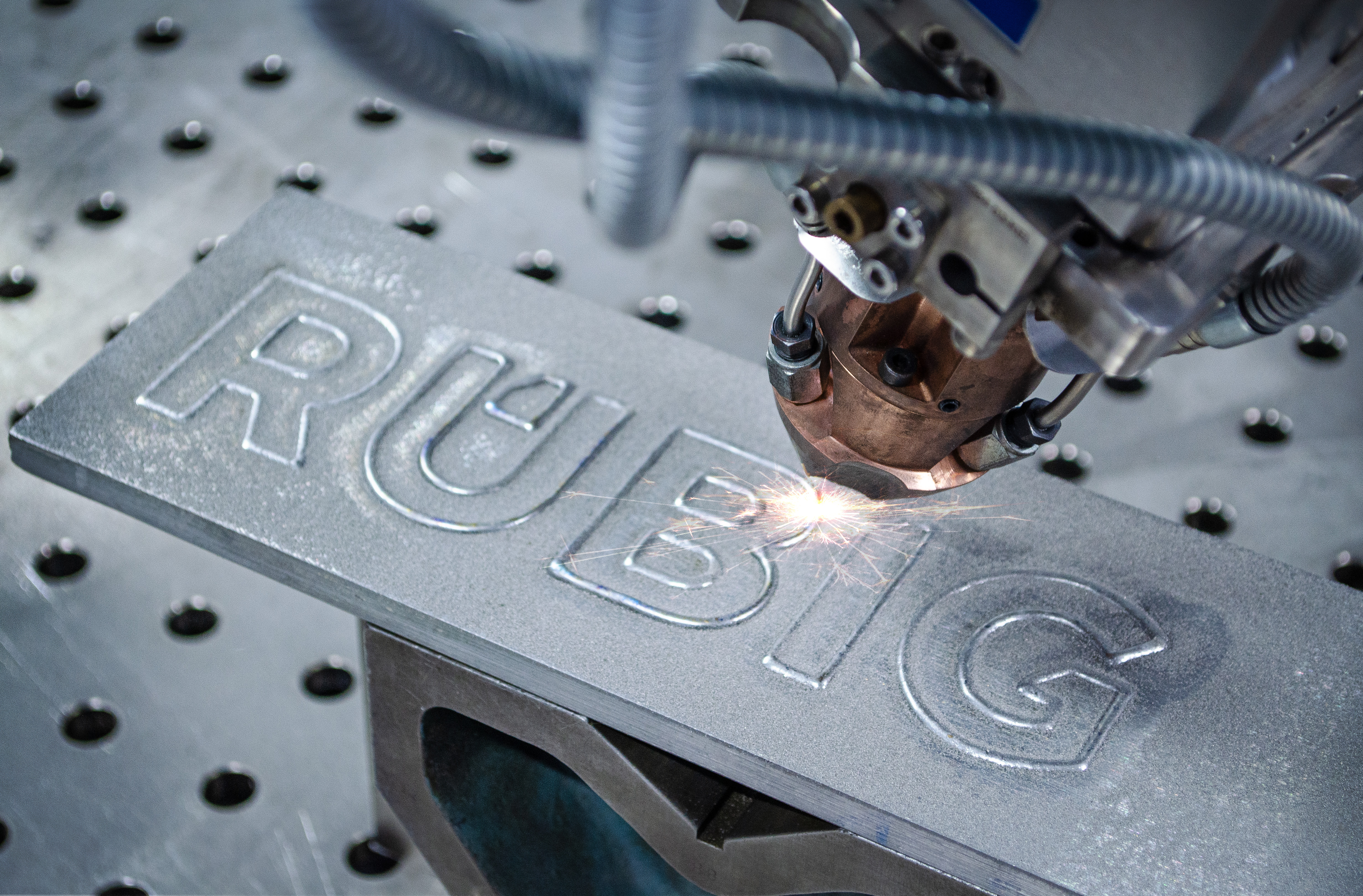

A total of 106 components, including mainly shafts, gears, sleeves and spacer rings, are heat treated at RUBIG Heat Treatment. The processes used include case hardening for a case hardening depth of 0.35 to 2 mm max as well as vacuum hardening and quenching and tempering for a hardness of 50 to 60 HRC each. RUBIG furnaces thereby comply with AMS Standard 2750, i.e. it guarantees:

- temperature uniformity in the working chamber

- instrumentation (specification of the measuring and control equipment)

- calibration of the measuring section from the controller via the measuring line to the thermocouple

- Tests of the system accuracy

At RUBIG Competence Center, RCC for short, even the most system-critical components are put through their paces. In this way, RUBIG can meet and guarantee the highest quality and safety standards.

Do you want to fly with us? Get in touch with us at ht.office[at]rubig[dot]com