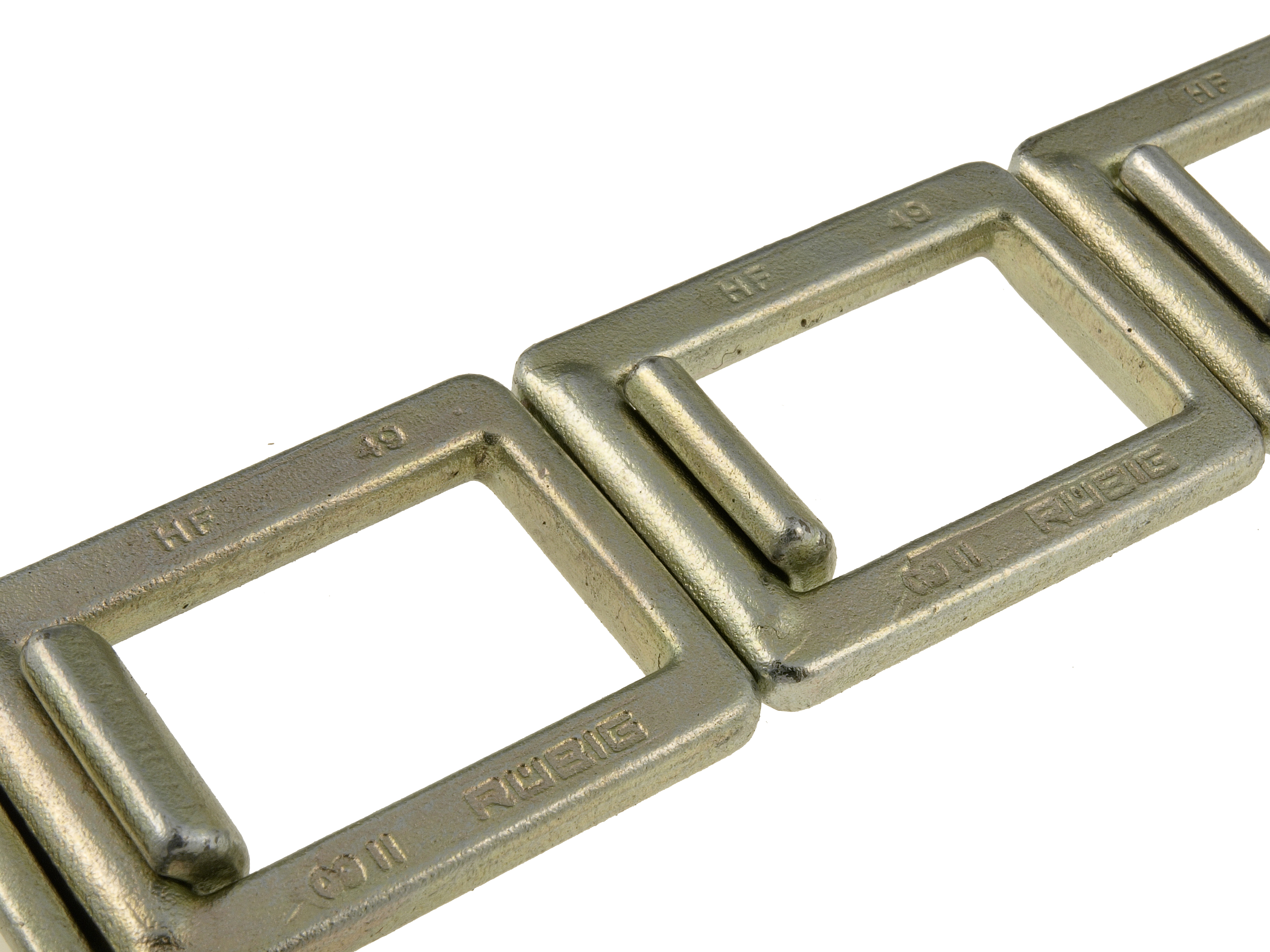

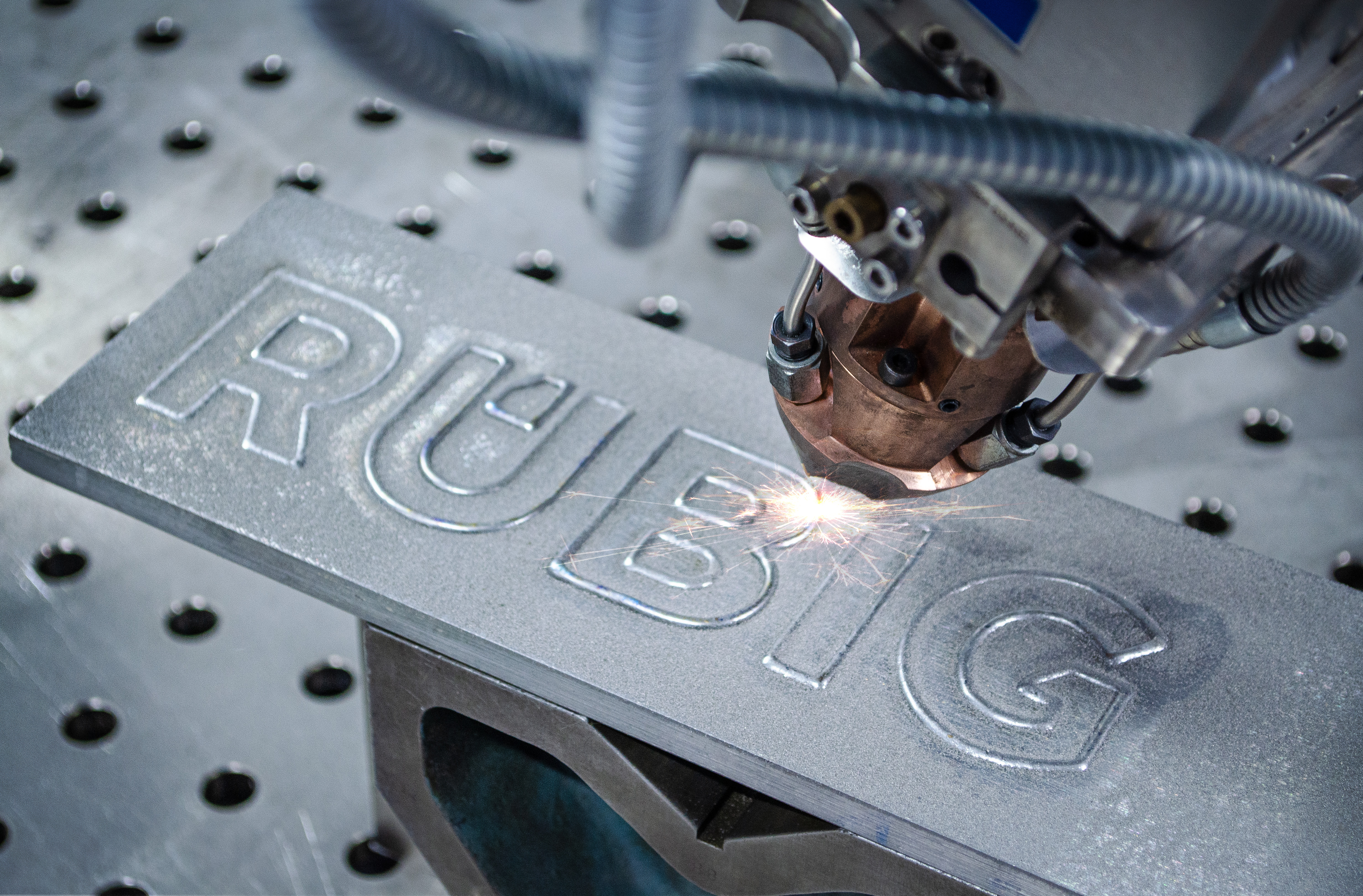

RUBIG’s role in the supply chain is the manufacturing of v-handles, door leaf supports, spacers, cranks, swivel arms and supporter arms. These components are safety components used for the opening and closing of doors in trains and trams. All parts are delivered ready-to-install. They are forged in various sizes, mechanically machined and finished and heat treated or coated. The tight tolerances, which are an essential quality criterion under safety aspects, present a great challenge. They require the entire process to be coordinated down to the smallest detail. Also, the dimensions of the components were whole new territory for RUBIG. The support arm presents the largest component in weight and size the forging hammers are still capable to produce. RUBIG Die Forge is therefore particularly proud of the successful course of this project.

On that note: be safe and mind the gap!