Voltage, current, and frequency can be varied within the following limits:

- Voltage: 0 – 700 V

- Current: 0 – 300 A

- Frequency: 125 Hz – 20 kHz

The system can be operated either in voltage-controlled (current adjusts) or current-controlled (voltage adjusts) mode. The resistance is defined according to the gas mixture, pressure, temperature, and spacings between the charged components and distance to the anode wall. The relevant variable then evens out according to Ohm’s law. In the basic package in addition, in each module it is possible to select monopulse, bipolar, or pure DC operation.

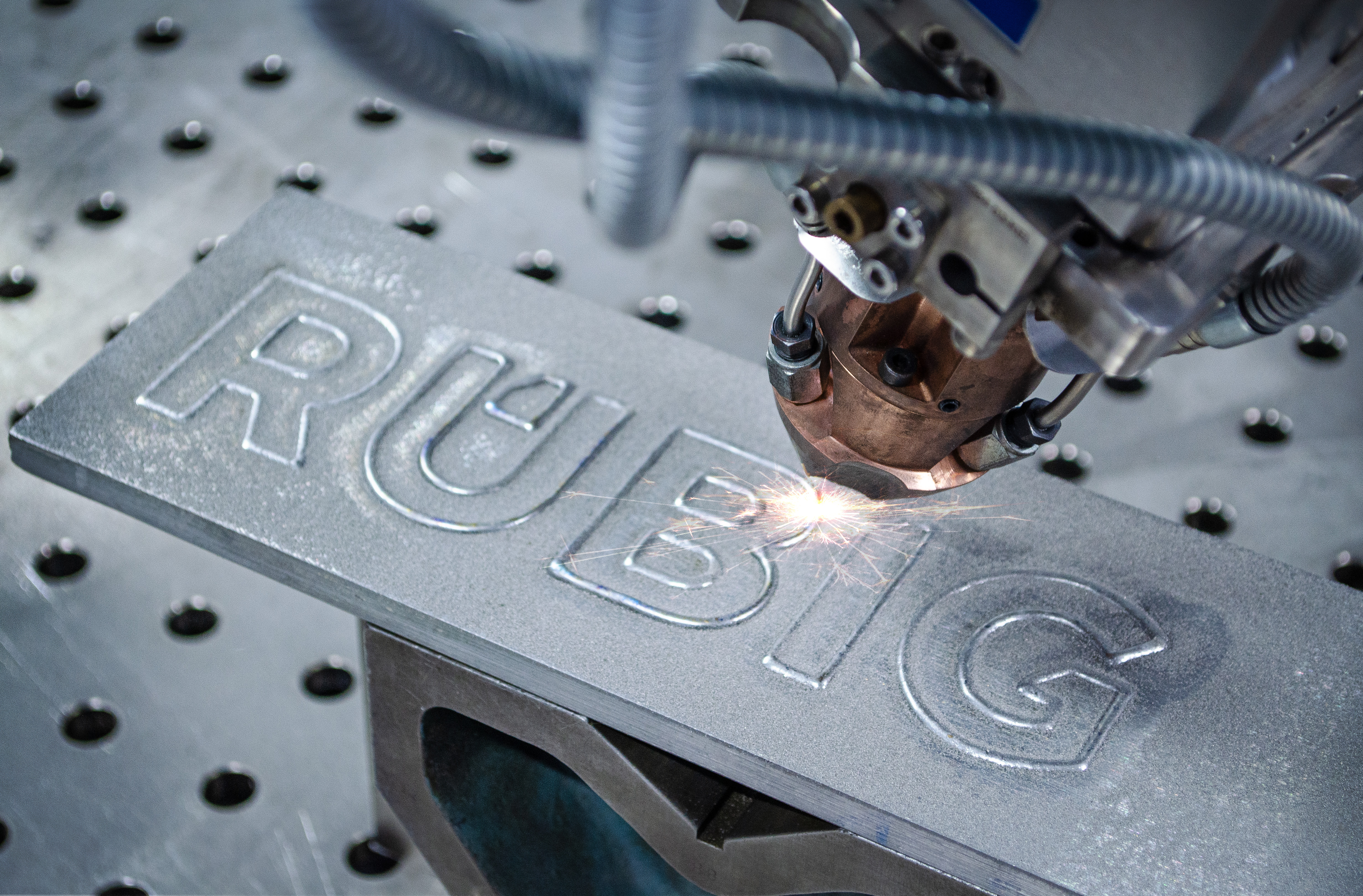

In addition to their reliable and energyefficient performance, RUBIG generators also benefit from a modular design. Their compact design allows them to be integrated rapidly within existing manufacturinglines.