There are 4 basic mechanisms that lead to wear:

- Abrasion (scratches, scoring).

- adhesion (material transfer, cold welding, scaling)

- tribochemical reactions (combination of corrosion and mechanical abrasion)

- surface fatigue (tongues, cracks, disintegration)

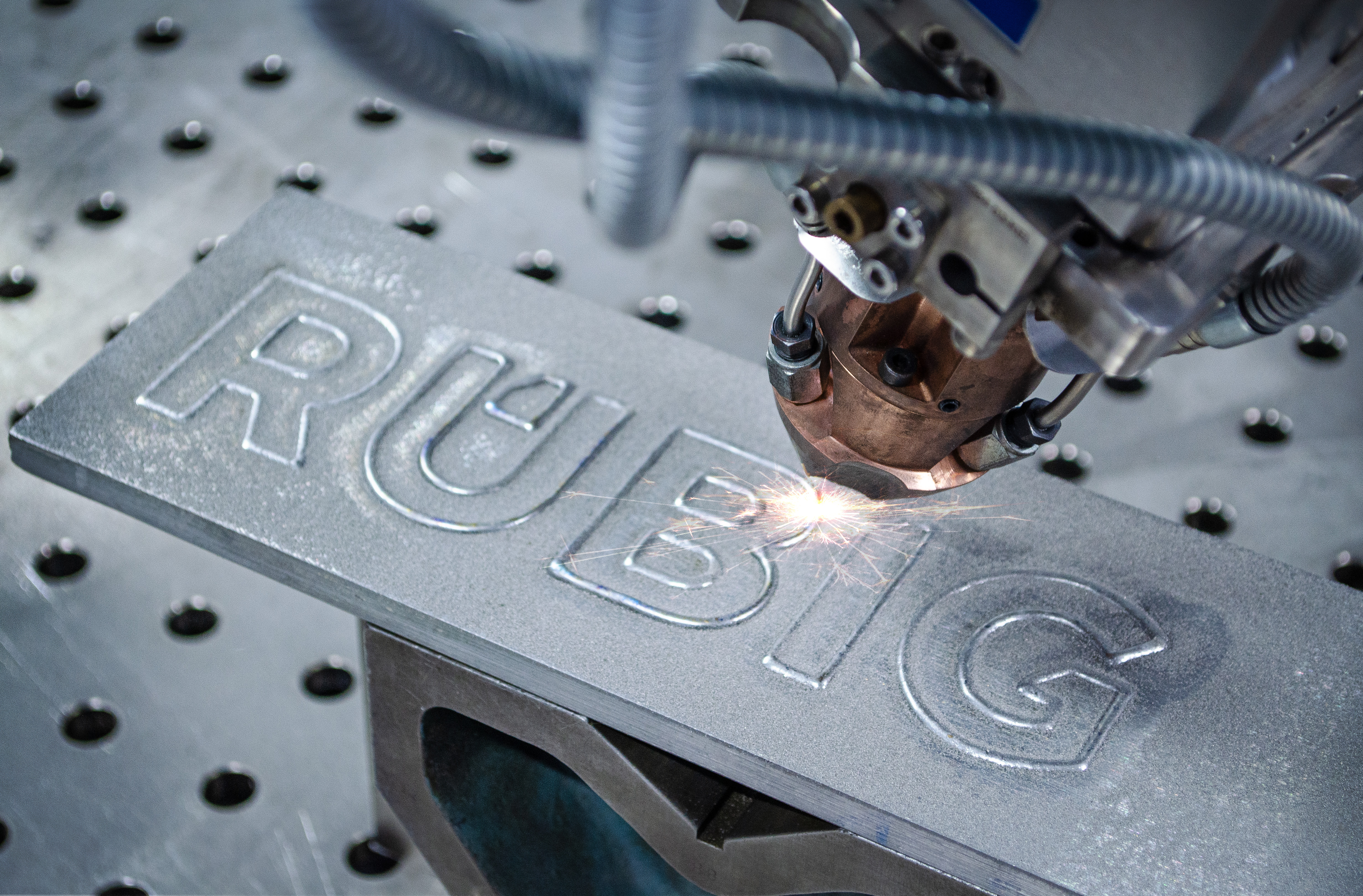

In most real wear damage, the 4 basic wear mechanisms rarely occur in pure form. In a tribological system, several mechanisms usually act simultaneously or with a time lag, with different proportions and can change over the duration of the load. To improve the wear behavior in a tribological system, it is therefore necessary to precisely analyze the entire system and derive appropriate countermeasures. The RUBIG Competence Center, RCC for short, combines materials science with the practical experience of metal finishing and processing and is a specialist in tribological investigations. Customers worldwide benefit from the exact analysis possibilities, the well-founded know-how and the resulting reliable and specific advice.