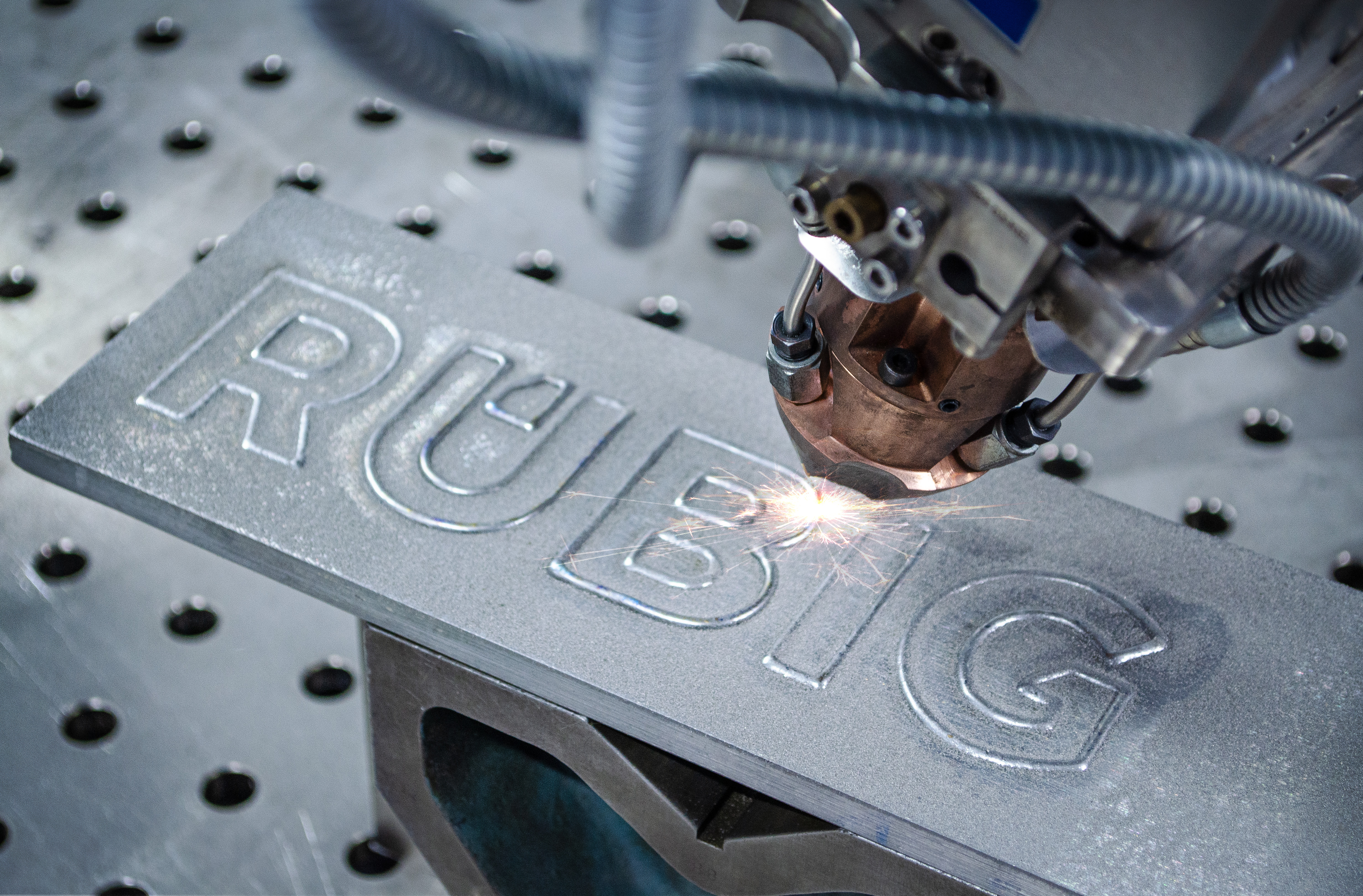

During LMD materials with desired characteristics are soldered on a substrate (of different material) to achieve the specific surface requirements. During laser hardening components are locally heated up by the laser beam and are then quenched from their own mass.

Laser hardening allows selective surface hardening with minimal distortion. The laser machining center works with 6 NC-controlled axes and has a working area of 1.955,00 x 1.393,00 x 650,00 mm.

If you want to find out more about LMD or hardening, please contact us!