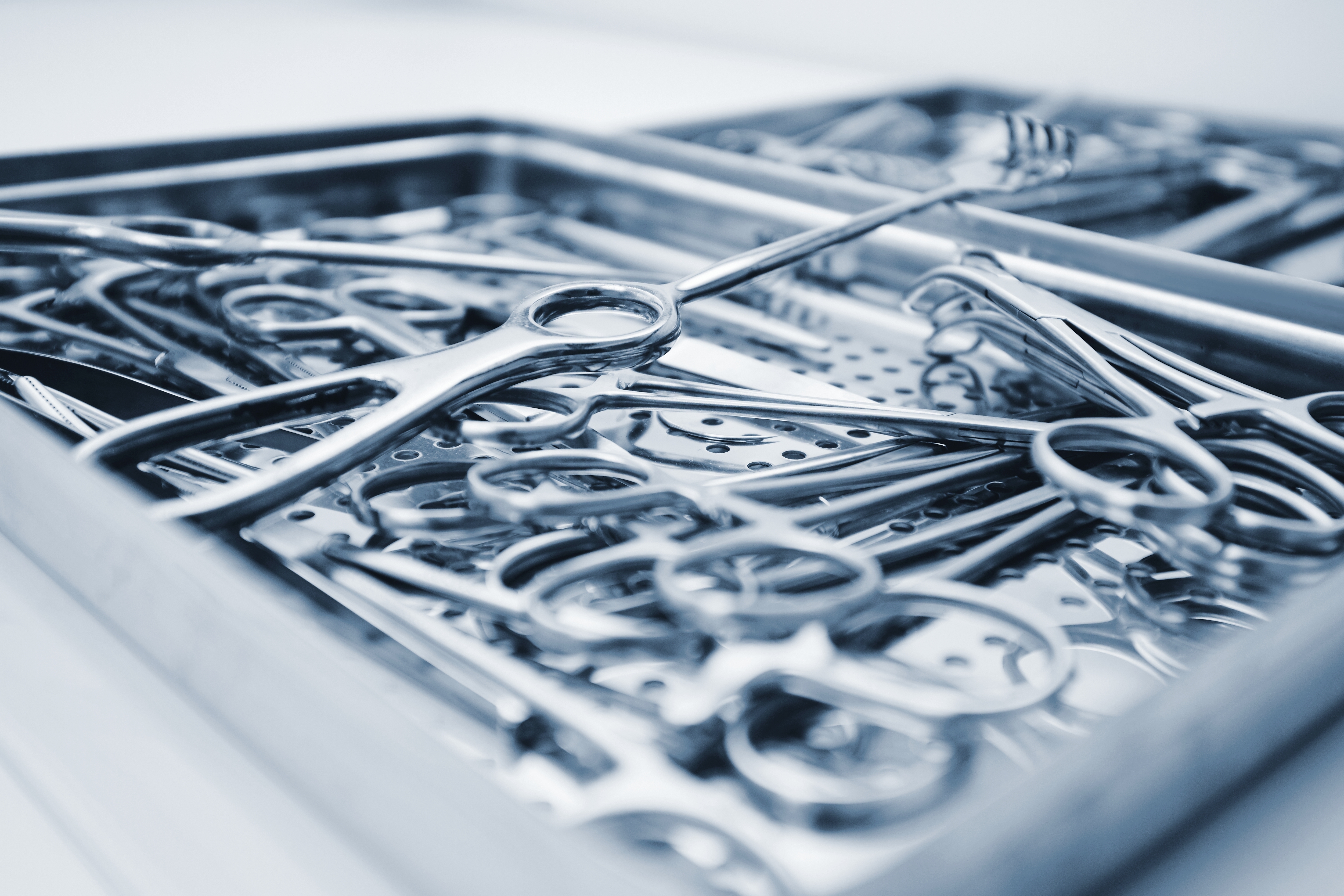

A nitrided layer in combination with post oxidation to create a black oxide layer increasingly replaces chrome plating. Especially plasma nitriding is a very environmental friendly process that diffuses nitrogen into the surface to increase wear resistance, fatigue strength and corrosion resistance. With a black oxide layer it results in a smooth and sleek black surface finish, great for applications like hydraulic cylinder bars, all kinds of pistons and many more. On top of that, it has a very aesthetic look and is able to retain lubricants such as oils. In addition a nitrided layer will not peel off, unlike chrome plating.

Industrial Furnaces

Industrial Furnaces

Locations

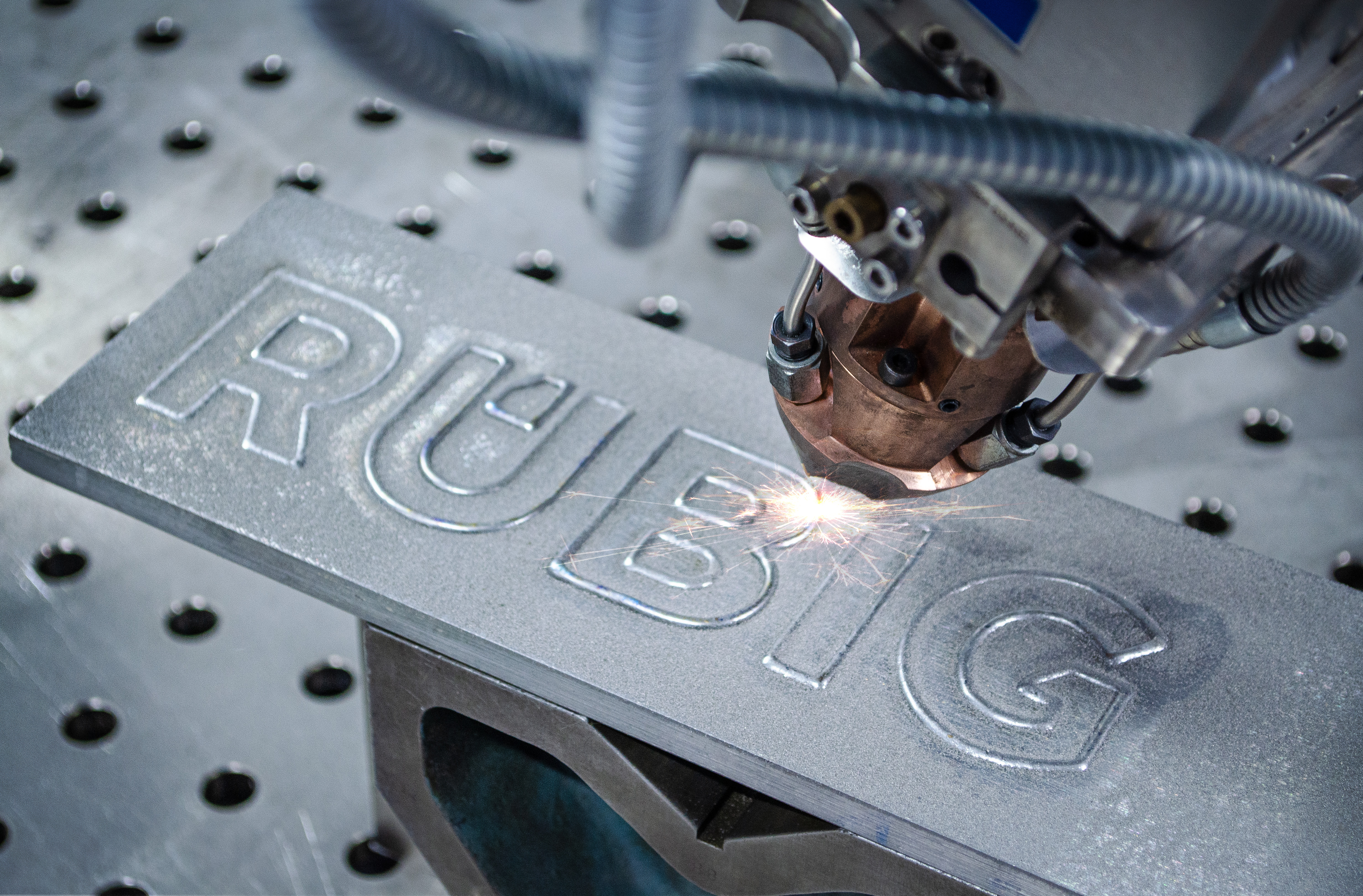

RUBIG Industrial Furnaces

RUBIG Industrial Furnaces

Our customers benefit from over 20 years of development experience in the field of customized thermal treatment systems for a variety of sectors.

RUBIG CN

RUBIG CN

Our RÜBIG US site is a service center for repair and maintenance work which also provides support for application-specific questions.

RUBIG US

RUBIG US

Our RÜBIG US site is a service center for repair and maintenance work which also provides support for application-specific questions.

Products

Plasma Nitriding System - MICROPULS® Everest

Plasma Nitriding System - MICROPULS® Everest

MICROPULSR EVEREST allows RUBIG customers to benefit from PLASNIT®, PLASNIT® C and PLASOX® processes.

DLC Coating System - MICROPULS® Diamond Xtended

DLC Coating System - MICROPULS® Diamond Xtended

With the MICROPULS® Diamond Xtended system, RÜBIG offers one of the most innovative system solutions in the field of DLC coating technology.

The Coating System - MICROPULS® Procoat

The Coating System - MICROPULS® Procoat

MICROPULS® Procoat is the optimum system solution in the area of hard coatings and provides the most advantageous solution in the industrial value chain.

PVD Coating System - MICROPULS® Lotus

PVD Coating System - MICROPULS® Lotus

Plasma Generator

Plasma Generator

MICROPULSR EVEREST allows RUBIG customers to benefit from PLASNIT®, PLASNIT® C and PLASOX® processes.

Gas Nitriding System - GASCON K2

Gas Nitriding System - GASCON K2

More than 20 years of experience have gone into RUBIG’s gas nitriding systems. Learn more about our GASCON K2 here!

RÜBIG Support

RÜBIG Support

Our specialists leave no questions unanswered. Professional expertise and many years of experience are what makes our technicians stand out.

Heat Treatment

Heat Treatment

RUBIG Heat Treatment

RUBIG Heat Treatment

Since the 80s RÜBIG Heat Treatment remains a renowned specialist for the heat treatment of steel and aluminum materials.

RUBIG Slovakia

RUBIG Slovakia

We provide you with a wide range of services when it come to steel as a material from case and vacuum hardening to gas and plasma nitriding.

Processes

Plasma nitriding - PLASNIT®

Plasma nitriding - PLASNIT®

The MICROPULS® technology developed by RÜBIG is utilized in RÜBIG systems to perform plasma nitriding processes in premium quality.

Hard coating - PLASTIT®

Hard coating - PLASTIT®

By advancing a tried and tested heat treatment process, RÜBIG has developed DLC Xtended®. Quality attributes include the internal coating and thick layers.

Vacuum hardening - R.VAC+®

Vacuum hardening - R.VAC+®

Precise process control and outstanding quality standards ensure consistent hardness, high strength and an optimum component framework.

Case hardening - R.CARB+®

Case hardening - R.CARB+®

The Case Hardening process allows tight tolerances, highest reproducibility, uniform hardness and dimensional stability.

Gas nitriding - R.NIT+®

Gas nitriding - R.NIT+®

Maximum flexibility, best marks for wear and corrosion resistance, and optimized properties for gliding and rolling stress.

Annealing

Annealing

Reductions in the quality of workpieces due to previous treatments such as rolling, bending, welding, etc can be revoked by means of annealing.

Markets

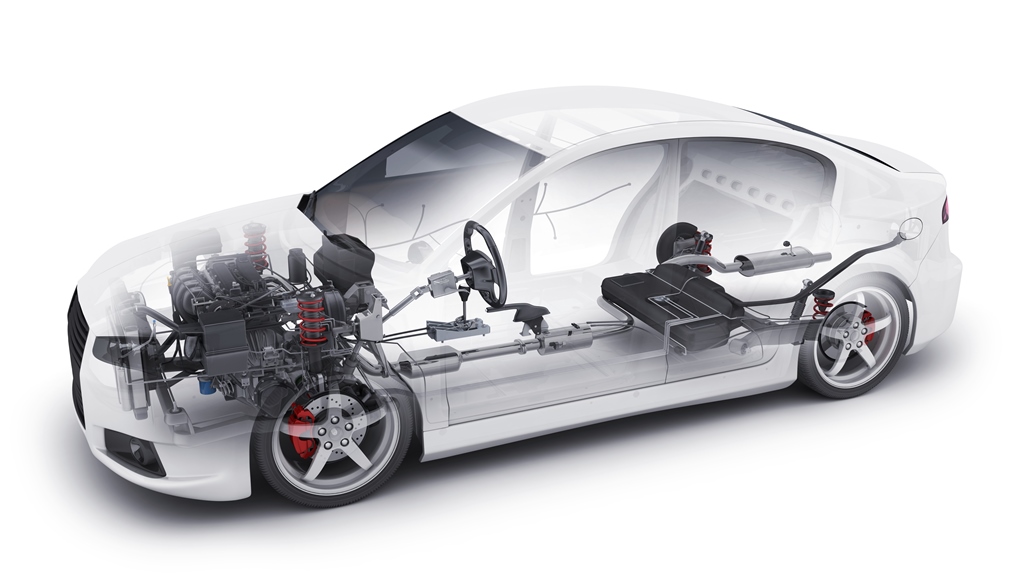

Automotive

Automotive

Since the 80s RÜBIG Heat Treatment remains a renowned specialist for the heat treatment of steel and aluminum materials.

Aerospace

Aerospace

Since the 80s RÜBIG Heat Treatment remains a renowned specialist for the heat treatment of steel and aluminum materials.

Aluminum

Aluminum

RUBIG ALUMINUM Treatments

RUBIG ALUMINUM Treatments

We offer different aluminium states such as T4, T5, T6, T7 with different quenching options (e.g. air quenching, polymer quenching, water quenching).

Die Forge

Die Forge

Die Forge

RUBIG Die Forge

RUBIG Die Forge

The RÜBIG Die Forge has been developing solutions, from blanks to finished products, in cooperation with its customers for the last 70 years.

Products & Services

Forgings

Forgings

Due to the longstanding experience of the RÜBIG Die Forge, forgings are executed from sketch to finished drawings and subsequently mass produced.

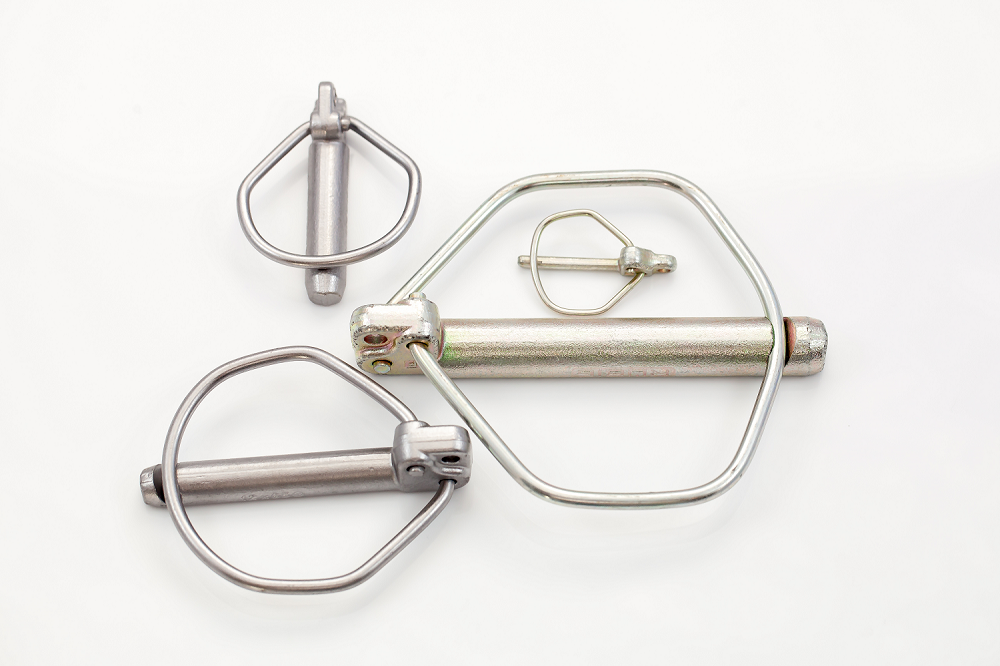

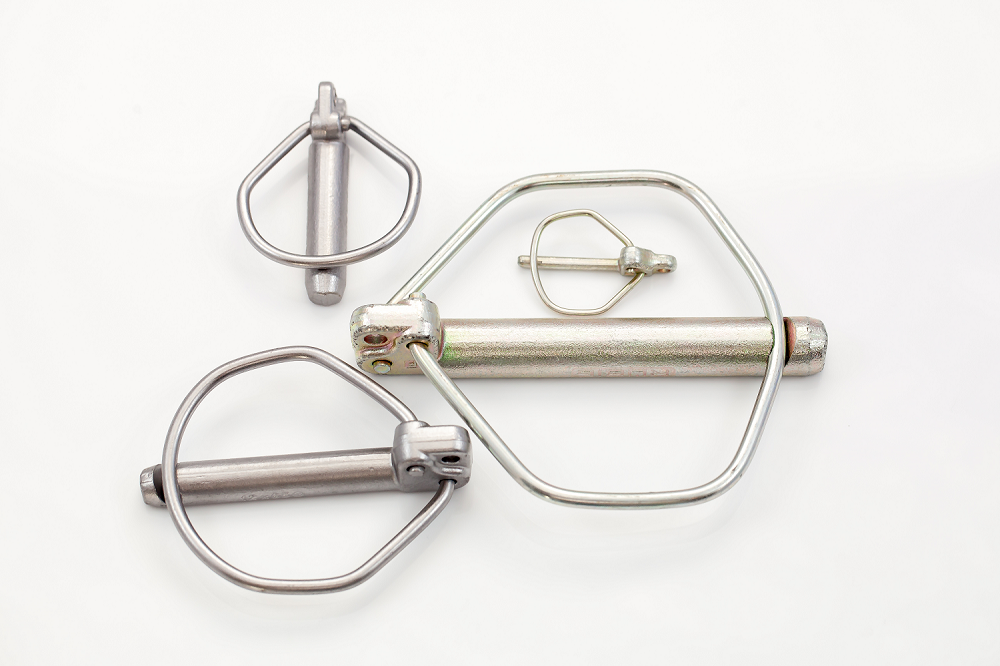

Safety Linchpins

Safety Linchpins

Linch Pins produced by the RÜBIG Die forge are durabile and safe due to innovative shape of the closing mechanisms. Learn more here!

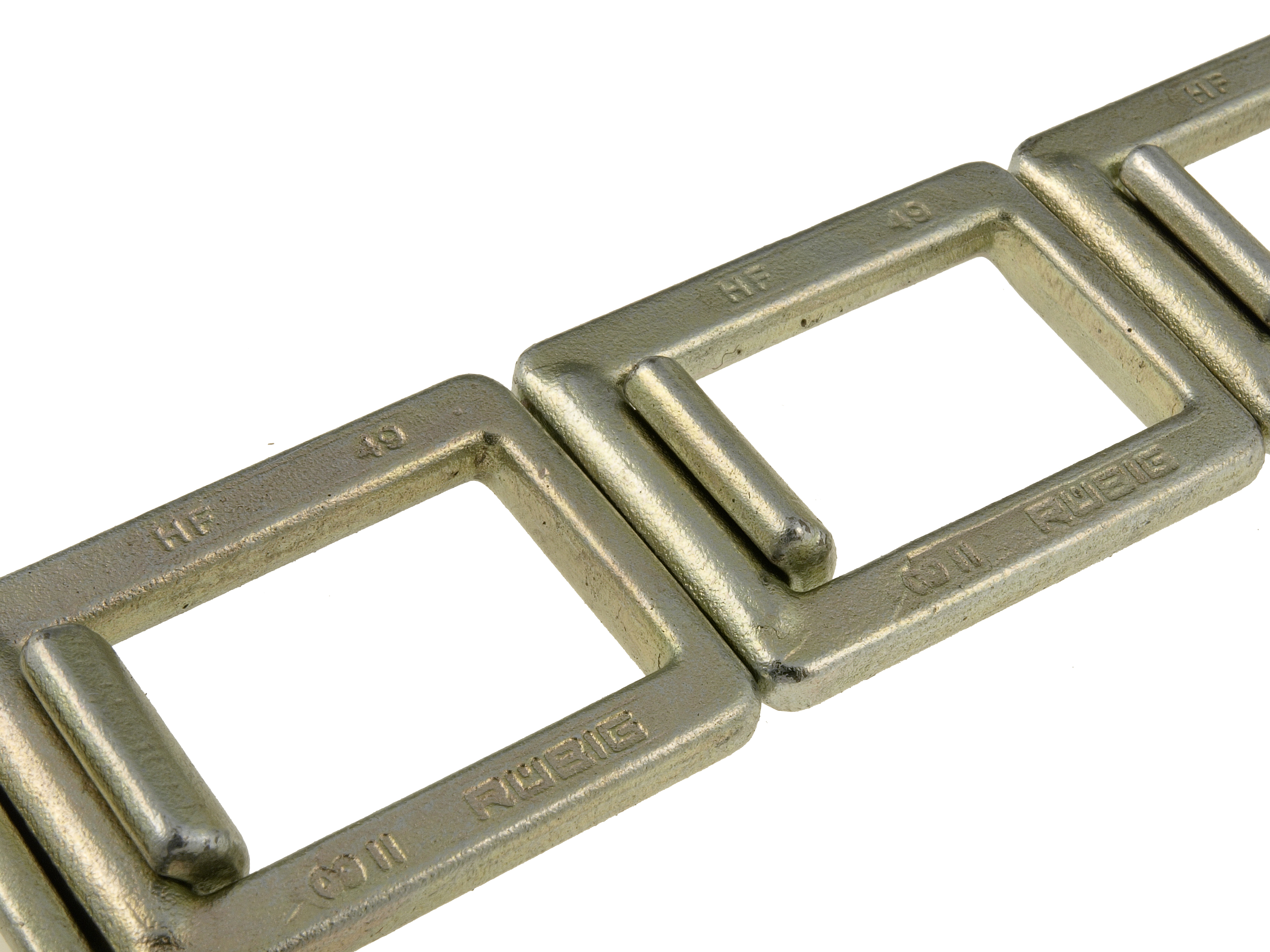

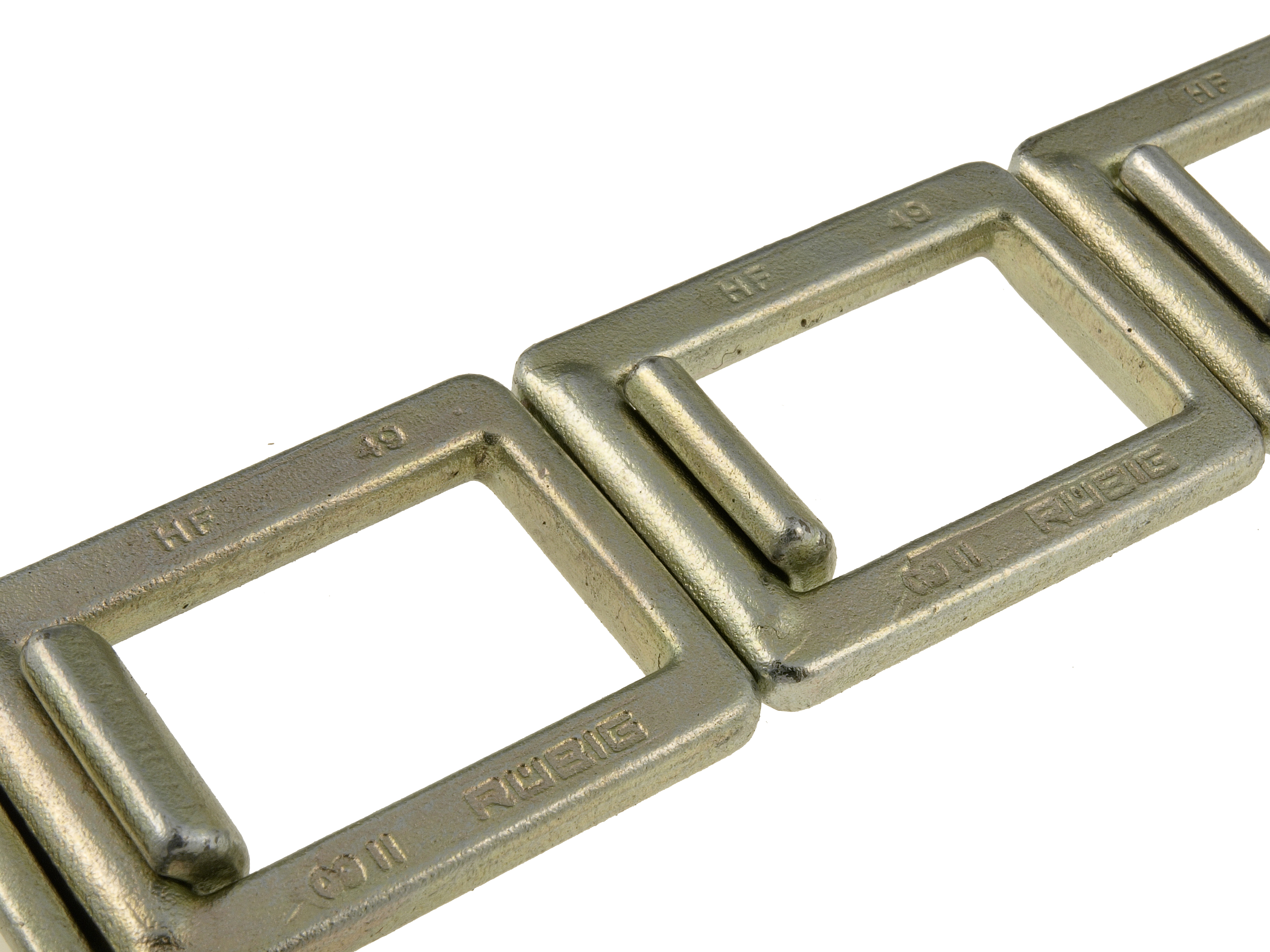

Drive and Conveyor Systems

Drive and Conveyor Systems

Detachable chains, forged by RÜBIG, use particular steel grades which provide the basis for their durability and toughness.

Leisure products

Leisure products

RÜBIG offers Hunting Knives, Knive Sharpeners and environmentally-friendly Anglers’ accessories made of steel. Click here for more information!

Machining Technology

Machining Technology

The RÜBIG Die Forge offers turning, drilling, milling, cutting and grinding and automatic workpiece measurement services.

Services

Services

RÜBIG offers Sandblasting, Welding, Hardening, Tempering, Vibratory grinding, Magnetic particle detection, etc. Learn more about our services!

Downloads

2D/3D Data download

2D/3D Data download

Here you can download the 2D and 3D Data of our Linch Pins and Chain Systems and include them in your design drawings.

Competence Center

Competence Center

The RCC consists of the R&D, the Heat Treatment, the Qualitative Analysis and the Failure Analysis department. Learn more about our services!

Research and Development

Research and Development

We provide our profound expertise in order to optimise or develop your components. Learn more about our R&D Department here!

Material testing

Material testing

Material & Damage Analysis, Hardness Measurements, Structural Assessments, Residual Austenite, Residual Stress Measurements & Corrosion Testing.

Company

Company

RÜBIG Group

Facts and Figures

Facts and Figures

In this section you can find Data and Facts about the RÜBIG Group.

Career

Career

Company videos

Company videos

Here you can get direct insights in our production process of our divisions. Click here to view our videos!

Support

Plasma instead of chrome - the environmentally friendly alternative

RUBIG GmbH & Co KG

Griesmühlstraße 4, 4600 Wels, AUSTRIA

Business hours:

Monday - Thursday: 7:00 - 17:00 o'clock

Friday: 7:00 - 14:30 o'clock

Saturday: 09:30 - 12:00 o'clock

Contact

Phone: +43 7242 66060 ● Fax: Extension 3077

E-Mail: ht.office[at]rubig[dot]com

© 2024 RÜBIG Österreich