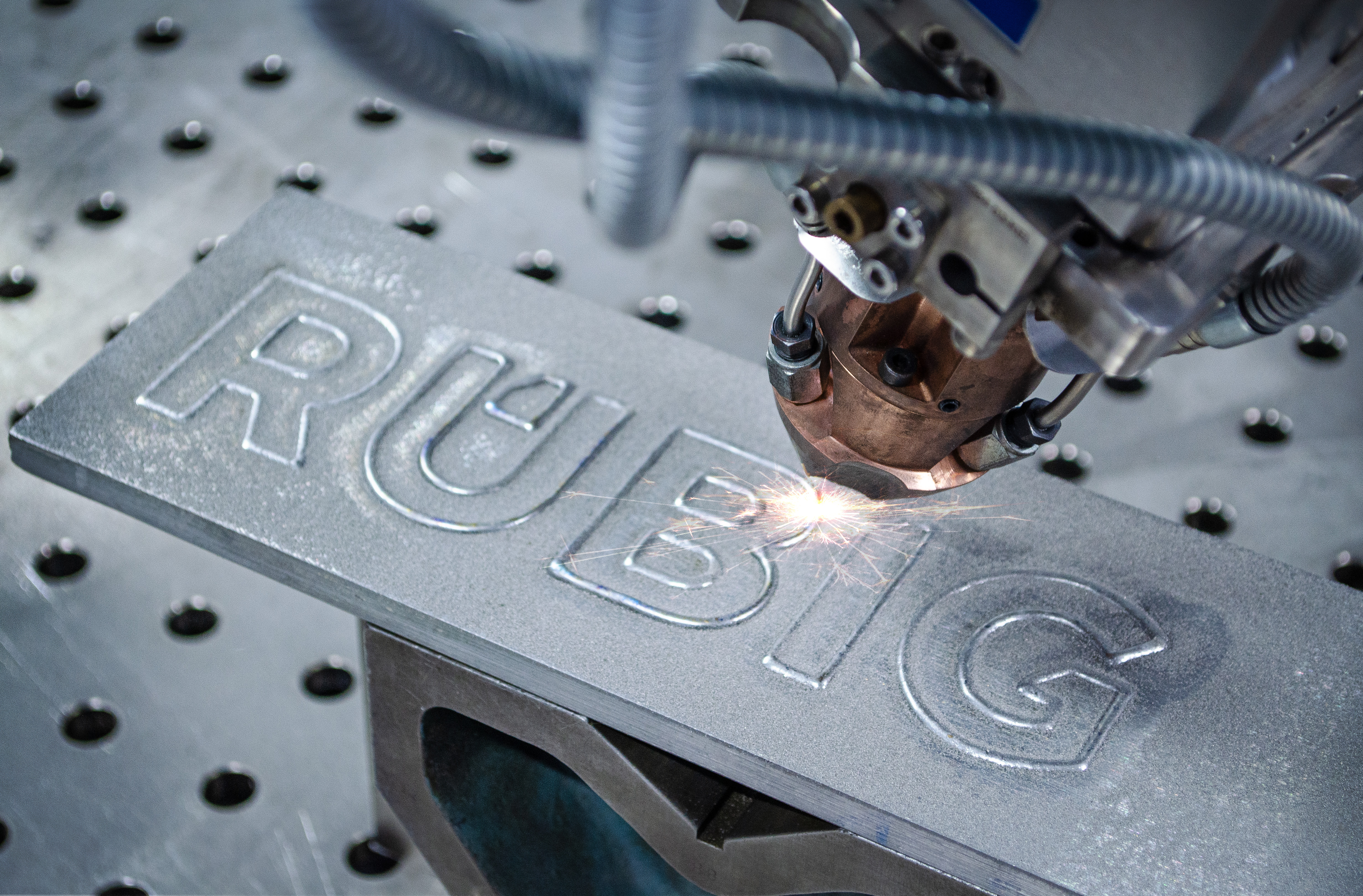

Based on the results of a field study, carried out by RUBIG, which were confirmed by a study from Bell, Sun et. al, plasma nitriding bears two major advantages compared to gas nitriding:

- less process gas consumption per functional unit and process-hour

- less NOx, CO and CO2 emissions

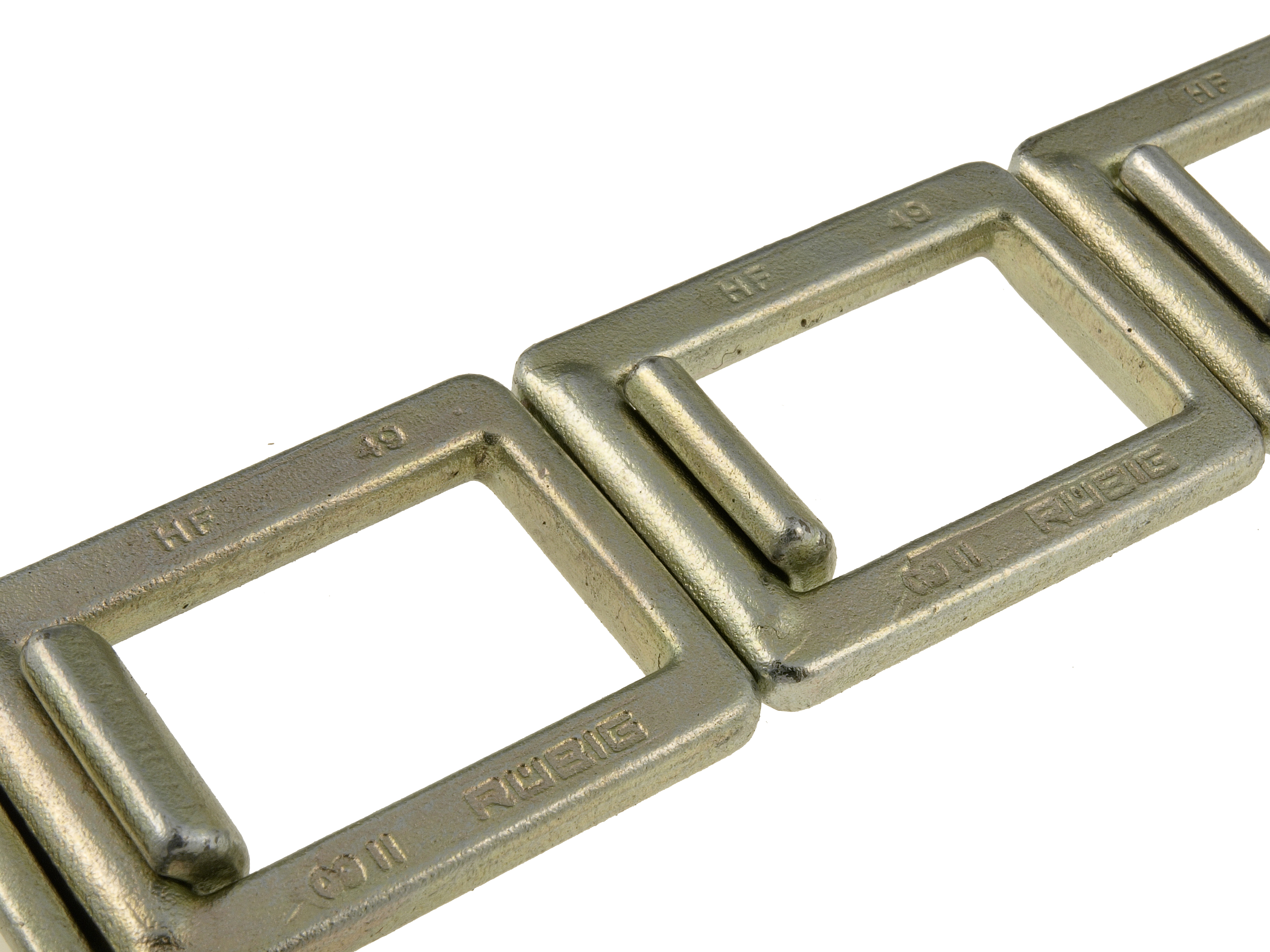

By increasing the total number of parts per batch and though the total surface that needs to be nitrided, RUBIG has achieved energy savings of more than 40% and cost reductions of 30% per part for its customers.