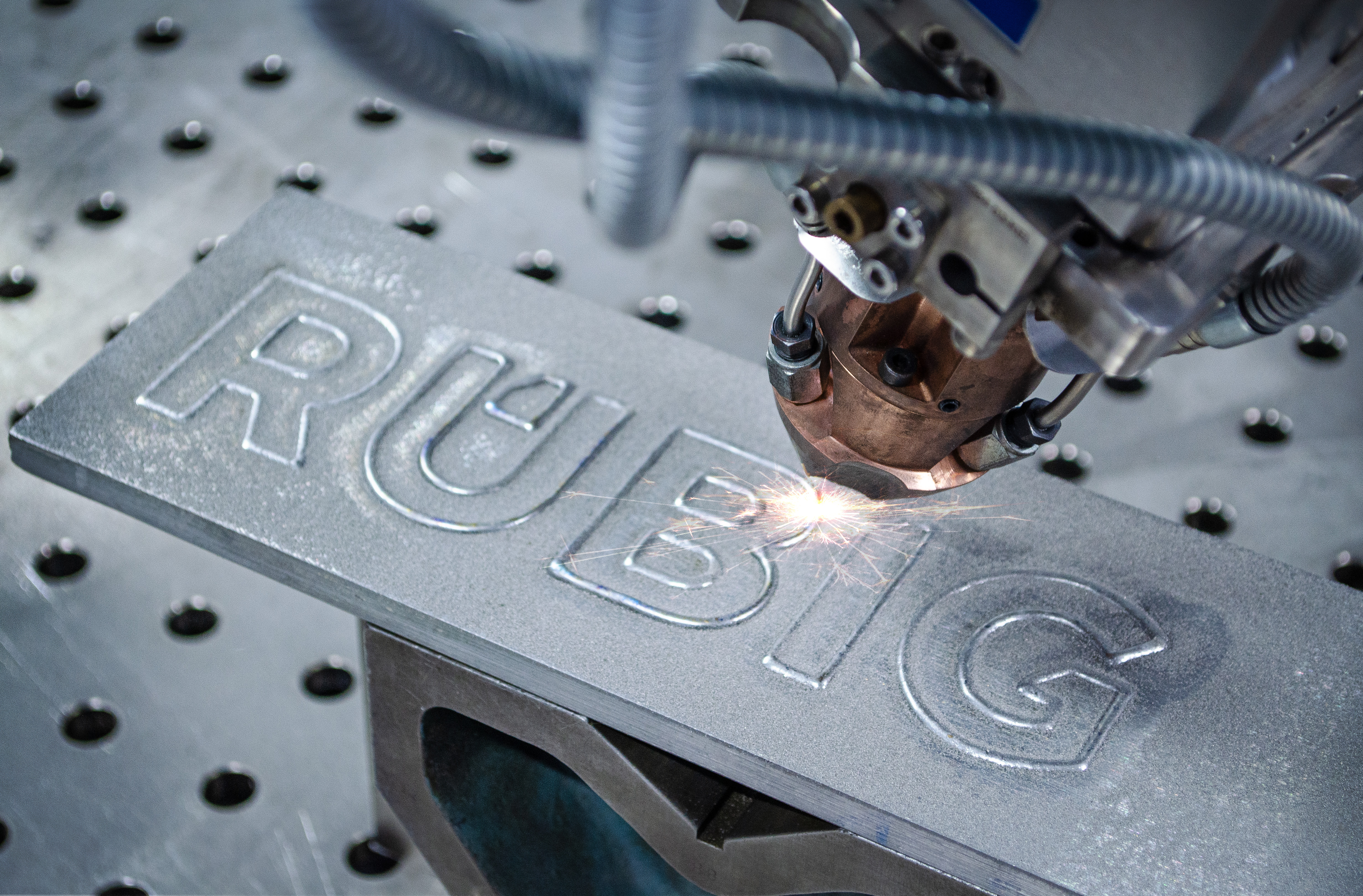

Within one year, an investment of almost 3 million euros in new equipment and infrastructure was made in an area of app. 400m². The focus of this newly established research location lies in the development and testing of new technologies in the areas of surface technology, heat treatment and manufacturing technology. The intent of this investment is to be able to offer RÜBIG's customers new solutions for wear and corrosion protection as well as the increase of fatigue strength in the medium term. The application possibilities of these technologies are as wide as its customers. Among other things, they offer the possibility of the reuse of aircraft turbine blades or the increase of the durability of blades, industrial knives or drill heads by many times. Special attention is paid to laser technology for "additive manufacturing".

All about Laser

The laser as the central element offers almost unlimited possibilities in this field. Technologies and processes such as laser deposition welding, laser hardening, laser cutting and welding can thus be further developed and optimized. Intensive research is also being carried out on PVD coating technology (physical vapour deposition). This opens up completely new possibilities for many in