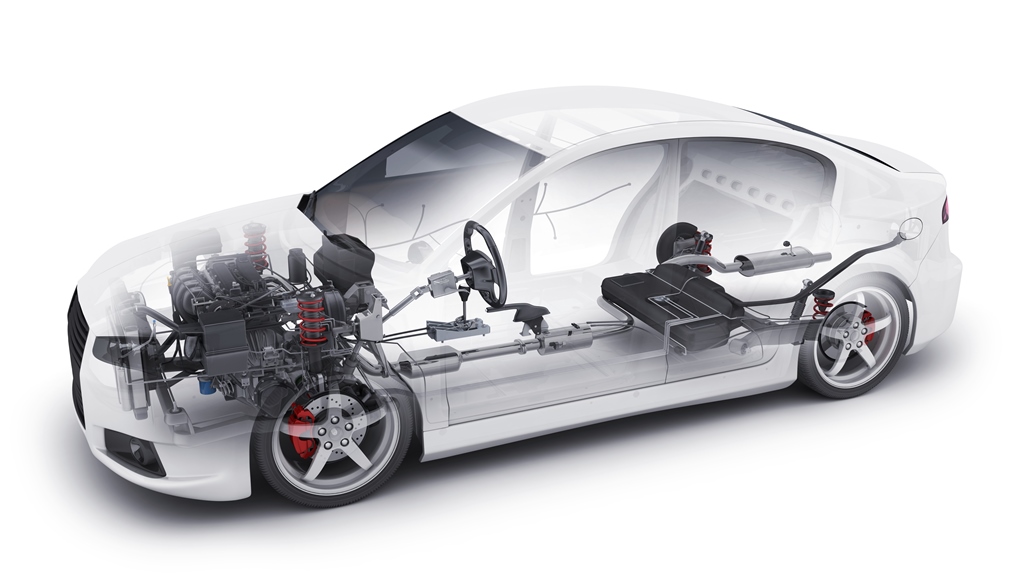

Complete solutions from a single source

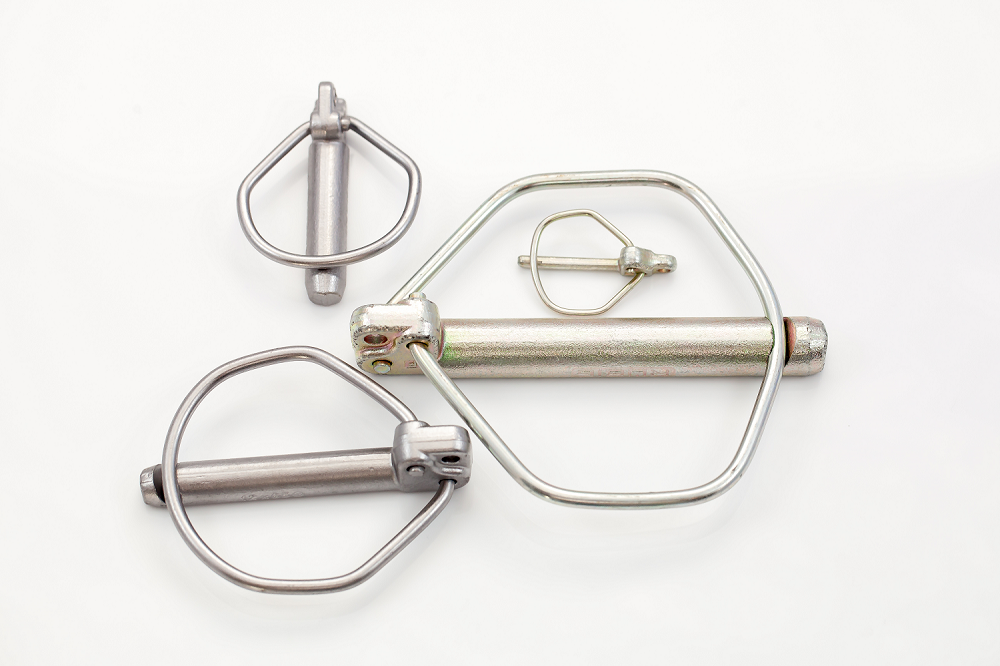

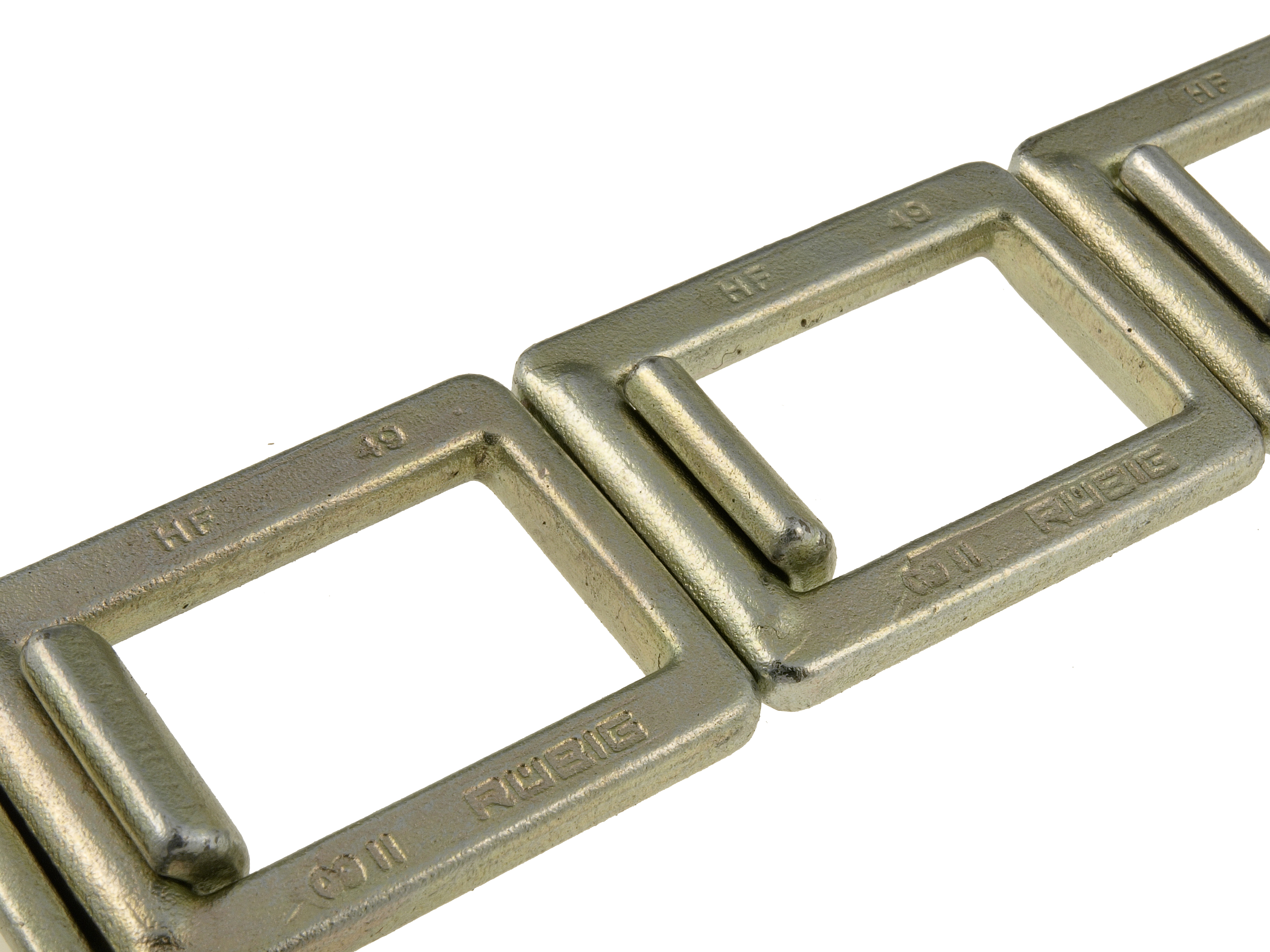

The core competency of the RÜBIG Die Forge is the production of drop-forged parts as well as their subsequent treatments. If needed, experienced employees can produce a design from the first sketch to the finished drawing and then cost effectively and reliably undertake the mass production of drop forgings.

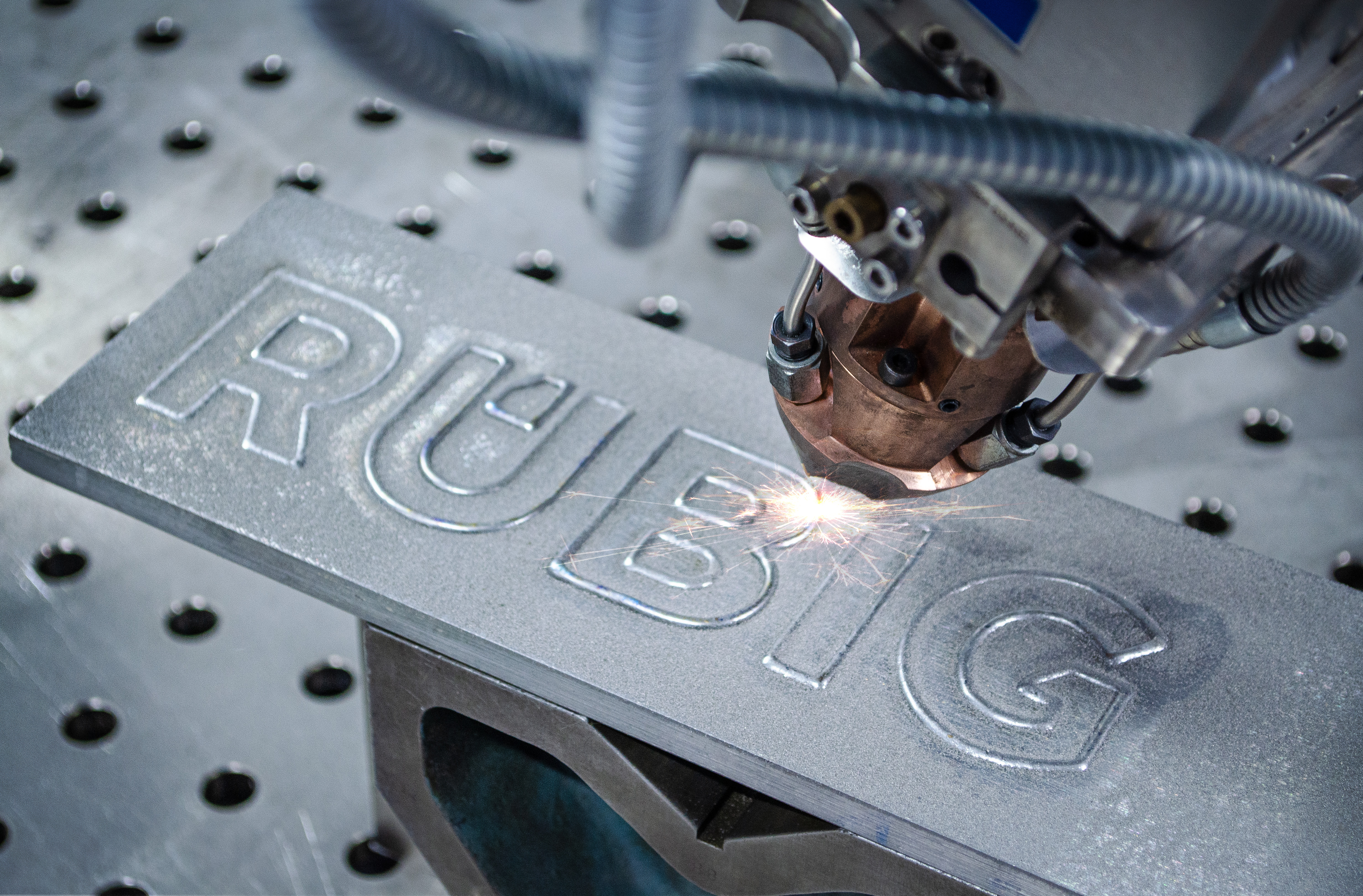

Besides the production of drop-forged parts, RÜBIG has specialized in the construction of complex components. For the machining of metals, multifunctional turning-drilling-milling systems are used to manufacture complex components. We also offer turning, drilling, milling, cutting and grinding and automatic workpiece measurement services. The interpolation of up to 5 axes makes it possible to machine any geometric shape efficiently and with maximum precision. This offers almost unlimited potential for workpiece complexity.

Our range of services:

- CNC turning chucking parts

- up to ø 300 mm

- distance between centres 1,000 mm

- CNC - bar-fed turned parts

- up to ø 42 mm

- magazine 1,000 mm

- CNC milling

- up to 800 x 1,000 x 1,000 mm

- up to 5 axes up to 120 tools

- Cutting

- up to ø 250 mm

- straight-cut and helical-cut to module 6

- spline profiles, serration, sprockets

- Flat grinding, vibratory finishing, etc.

Contact:

RÜBIG Die Forge

Tel.: +43 7242 66060

Fax: DW-3077

E-Mail: ht.office@rubig.com