FEASIBILITY ANALYSIS

You send us the drawing and material; we check potential nitriding depths, distortion tolerances, and cost effects.

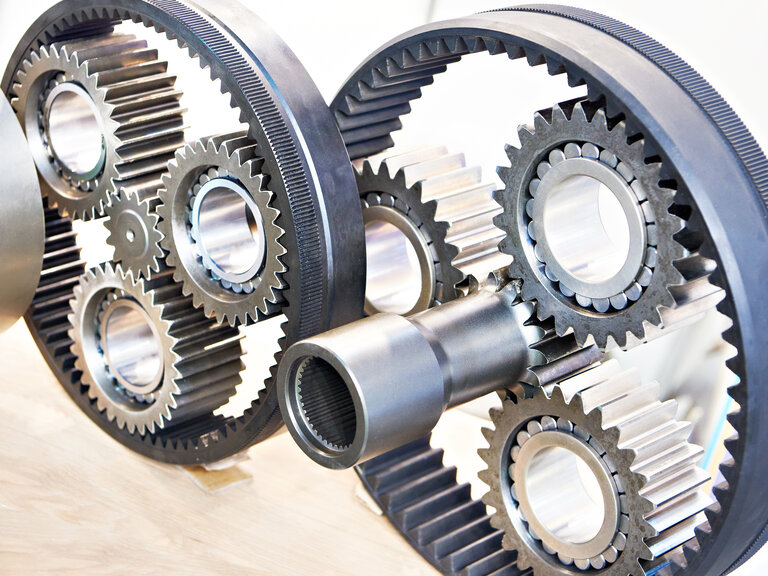

Ring gears in electrified drivetrains today must unite two opposites: maximum strength and minimal weight.

However, when these thin-walled components are treated with conventional methods such as case hardening, a well-known issue arises – distortion. High temperatures around 900 °C, followed by rapid quenching, expose the gear rings to extreme stresses. As a result, the component may become oval or fail to maintain flatness and runout tolerances, leading to costly grinding and straightening operations.

This is precisely where PLASNIT®, RUBIG’s Micropulse Plasma Nitriding process, comes into play.

During case hardening, carbon first diffuses into the steel at high temperatures. The workpiece is then rapidly quenched, forming martensite – hard, but full of internal stresses. For solid gears, this process works reliably. However, in ring gears with thin wall thicknesses, even microscopic changes in the microstructure can add up to significant geometric deviations: the component may come out of the furnace oval instead of round, the internal gearing may lose concentricity, and the previously ground bore may require rework.

Each of these corrections increases production time and cost. In some series, post-hardening rework operations account for more than one-third of the total process costs.

PLASNIT® uses an ionized nitrogen–hydrogen gas mixture at comparatively moderate temperatures of around 500 to 540 °C. In this plasma, nitrogen becomes activated, diffuses into the surface zone of the steel, and forms a finely structured diffusion layer with compressive residual stresses.

Because the component is not quenched, phase transformations do not occur; instead, the stresses introduced during heating are gradually relieved in a controlled manner. The result: the gear set retains its original shape, even with very thin ring walls.

Through precise process control, it is possible to form a compound layer—which provides high wear resistance—specifically on the tooth flank, but not in the tooth root. In the root area, a sufficient and homogeneous diffusion zone is required to build up compressive stresses, but the compound layer itself—due to its microporosity—is undesirable, as it can act as a crack initiator.

As early as 2007, the Gear Research Centre (FZG) at the Technical University of Munich, under the direction of Prof. Höhn, investigated the fatigue strength of plasma-nitrided steels. Nitriding steels such as 31CrMoV9 achieved tooth root strengths up to 590 MPa and flank load-carrying capacities up to 1,760 MPa – values at the upper end of the range typically achieved by case-hardened components.

Within its internal research programs, RUBIG has transferred these findings to actual series components: ring gears that previously required grinding after case hardening due to ovality came out of the furnace without any rework after switching to PLASNIT® – with equal or even improved strength values. The cost savings per component exceeded fifteen percent.

Plasma nitriding offers more than technical stability. Because distortion is very low and mainly results from the relaxation of residual stresses introduced during mechanical processing, the gear can be plasma nitrided in its finished state or with small dimensional allowances.

Production costs shrink on two fronts: firstly, grinding, honing, or straightening are eliminated; secondly, scrap rates are reduced because rejects practically no longer occur.

At the same time, energy consumption decreases, since lower temperatures are sufficient and no oil quenching is required. Companies that want to improve their CO₂ balance or ensure REACH compliance will find in plasma nitriding a process without toxic hardening salts or explosive furnace atmosphere.

Where case hardening involves oil quenching baths and exhaust gases, PLASNIT® operates almost emission-free. The ionized gas is recycled within the chamber circuit; chromium(VI) or cyanides do not occur. When the furnace is operated with green electricity, the process is even climate neutral.

In addition, the personnel benefit from a clean, odorless working environment without any risk of explosion.

The switch to electric drives brings new transmission concepts: compact planetary gearboxes that must transmit high torques quietly. Thin-walled ring gears are the heart of these systems. With PLASNIT®, they can be hardened without any geometric compromises. This facilitates lightweight construction, reduces noise generation, and extends service life – all key objectives in electric vehicles.

New production lines can integrate plasma nitriding processes from the outset; existing manufacturing facilities can be retrofitted with turnkey MICROPULS® systems.

A manufacturer of heavy all-wheel-drive axles originally used a case-hardened internal ring gear. Despite complex clamping devices, regrinding was unavoidable in order to achieve quality class 7.

After switching to PLASNIT®, the deviations in roundness and flatness remained so small that not a single grinding pass was required. The cost per ring gear decreased by around 17 percent. The throughput time was reduced by almost ten percent, and noise measurements on the roller test bench confirmed a more uniform load distribution and noticeably quieter operation of the gearbox.

FEASIBILITY ANALYSIS

You send us the drawing and material; we check potential nitriding depths, distortion tolerances, and cost effects.

SAMPLING & TEST BENCH VERIFICATION

Test specimens are plasma nitrided and tested on FZG test benches so you receive reliable data for your release process.

SERIES INTEGRATION

Whether contract hardening in our facilities or installation of a MICROPULS® system in your production – we provide the right concept.

SUPPORT & TRAINING

Process parameters, quality assurance, maintenance – your team receives comprehensive training to ensure lasting benefits.

A helical ring gear for a planetary gearbox (flange Ø 125 mm, width 32 mm, m = 1.5) showed significant dimensional and form deviations after conventional mandrel case hardening. Profile and flank line errors were consistently in the range of several µm; the roundness of the flange drifted considerably. These deviations made subsequent grinding unavoidable, increasing both lead time and costs.

The customer commissioned RUBIG with a sample batch which—using the same material (31CrMoV9)—was plasma nitrided. The decisive factor was the elimination of the martensitic quenching shock: during the PLASNIT® process, nitrogen diffuses into the surface zone at 500–540 °C; quenching is not required.

The internal quality evaluation of ten gears each showed the following:

All gear and flatness tolerances thus remained within finishing values; hard regrinding was no longer necessary. The study confirms that the maximum differential values after PN were only about half as high as after DEH.

Due to the elimination of grinding, straightening, and additional measurement time, the total cost per ring gear decreased by around 12–17 %. At the same time, the average production lead time was reduced by almost 10 %.

* The stated layer properties are based on depositions under optimal conditions. Depending on factors such as surface finish, component size, material, and other boundary conditions, the properties may vary on the actual component.

RUBIG Die Forge combines cutting-edge technology and extensive industry expertise to refine your steel products to perfection.

Head of Sales – Heat Treatment