Heat Treatment

of Steel

no compromises

The interplay of these mechanical properties makes every steel unique. By using RUBIG heat treatments, you can improve and control these properties. treatment can also be used to remove stresses in the steel and improve its weldability and corrosion resistance.

Whether hardening, nitriding or annealing: Choose from the different processes. Our experts will be happy to advise you.

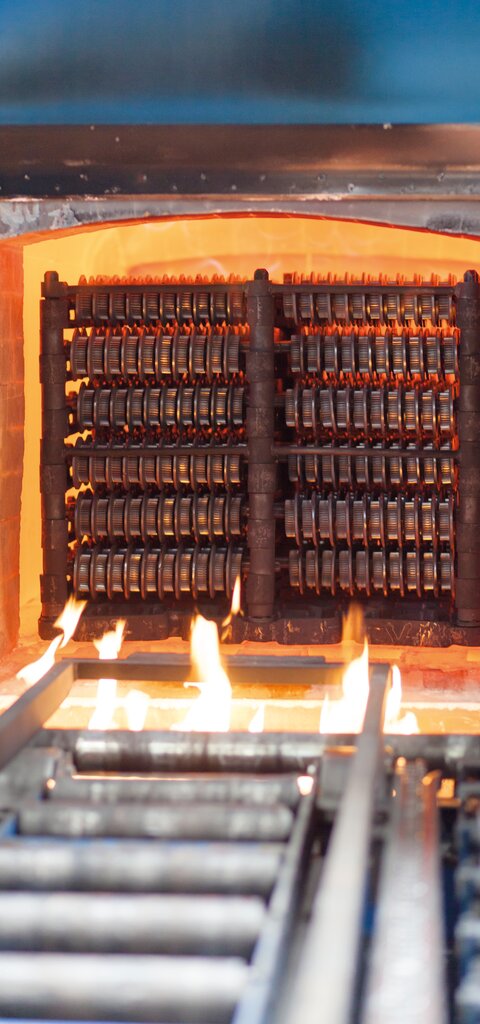

Heat treatment refers to the controlled heating, soaking, and cooling of steel in order to influence its microstructure and properties in a targeted way. Hardening technology is the sub-discipline focused specifically on increasing hardness, wear resistance, and fatigue strength.

Typical target values in hardening technology:

These properties are crucial for components used in mechanical engineering, the automotive industry, toolmaking, and medical technology.

The key to component performance

Precisely controlled thermal and thermochemical processes are used to tailor the mechanical properties of steel. The goal is to make components more resistant, durable, and capable of withstanding higher loads—specifically matched to their later application.

RUBIG is among the leading providers in hardening technology and heat treatment. With decades of experience, proprietary patented processes, and state-of-the-art plant technology, RUBIG delivers solutions for the highest industrial requirements—from single parts to high-volume series production.

Hard surface, tough core

In case hardening, the steel is first carburized and then hardened. This classic hardening process produces an extremely wear-resistant case while maintaining a tough core.

Typical applications:

RUBIG implements case hardening with R.CARB+ , a highly precise and energy-efficient process.

Precise and low-distortion

Vacuum hardening is one of the highest-quality processes in modern hardening technology. Heat treatment takes place under vacuum, preventing oxidation and decarburization.

Advantages of vacuum hardening:

Here, RUBIG relies on its proprietary R.VAC+ technology, designed to deliver maximum process reliability.

Wear-resistant and corrosion-protective (R.NIT+)

In gas nitriding, nitrogen is introduced into the steel surface, forming a diffusion layer and a compound layer. The key benefit is high wear resistance while maintaining good dimensional accuracy. RUBIG offers gas nitriding as a premium heat treatment under the name R.NIT+ .

Options and variants (depending on requirements):

• Nitrocarburizing (additional enrichment of the surface with carbon)

• Post-oxidation for added corrosion protection and optimized friction/sliding properties (e.g., GASOX )

Minimal dimensional change (PLASNIT)

Plasma nitriding is a nitriding technology that is particularly low in distortion. RUBIG offers plasma nitriding under the brand name PLASNIT , with highly variable process control to optimally match material, component geometry, and target properties.

Special treatments:

• PLASOX : plasma nitriding followed by oxidation

• PLAPOL: an exceptionally hard, wear-resistant surface (ideal, for example, for tool steels)

Properly executed heat treatment has a decisive impact on:

Wrong process selection or insufficient process control often leads to distortion, cracking, or inadequate hardness. RUBIG addresses these risks with deep materials-engineering know-how, precise process control, and comprehensive consulting.

Choosing the right process depends on several factors:

RUBIG supports customers from material analysis through production release and develops tailored heat treatment and hardening concepts.

RUBIG works to the strictest quality standards. All heat treatment and hardening processes are documented, traceable, and aligned with industrial standards. State-of-the-art testing and measurement technology ensures that every component meets the required specifications precisely.

In addition, RUBIG offers seminars and training. In hands-on courses, RUBIG provides in-depth expertise in materials science, process selection, error prevention, and quality assurance. These seminars are aimed at design engineers, manufacturing engineers, and decision-makers who want to better understand, evaluate, or implement heat treatment processes themselves.

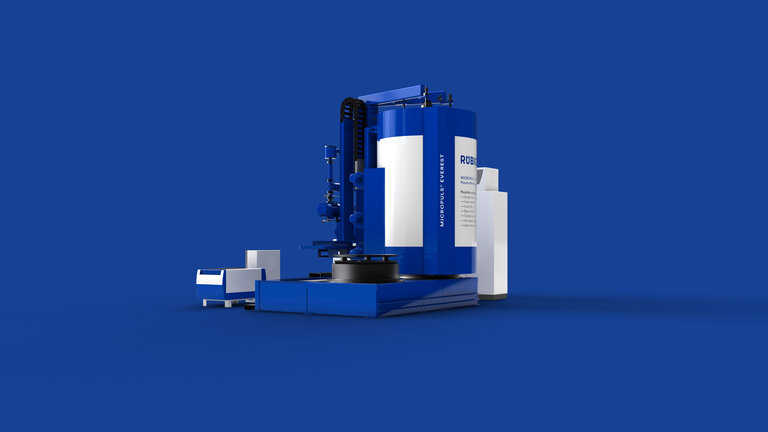

With RUBIG systems you can carry out the presented procedures yourself.

Find out more about the types of furnaces RUBIG offers here!

RUBIG combines state-of-the-art technology and in-depth industry knowledge to optimise the finishing of your steel products.

Head of Sales – Heat Treatment