Maximum usable furnace space: Ø 1,500 mm/6,000 mm height

Maximum batch weight: 10.000 kg

Our PLAPOL layer is applied to the surface in a diffusion process at low temperatures.

The aim is to incorporate atoms into the matrix of the steel in a similar way to nitration, without the formation of compounds such as nitrides.

Thus, PLAPOL is ideal for tools made of tool steels with an tempering temperature above 400°C (e.g. 1.2343, 1.2311, 1.2316, 1.2083), with maximum dimensions of Ø 1,500 mm x 2,400 mm depth. The PLAPOL layer with a diffusion strength of 10 - 70 µm has a hardness of over 1,000 HV, is highly wear-resistant, can be re-polished and welded for repair. Since it is a diffusion coating there is no growth or flaking. Due to the low treatment temperature, the risk of distortion is minimal.

Due to the low hardening depth, we recommend PLAPOL treatment only for tempered or hardened steels.

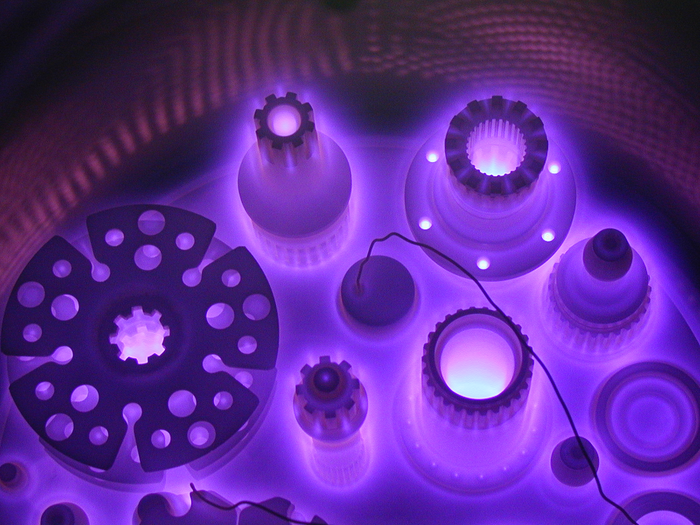

Our plasma nitriding system

EVEREST

The plasma nitriding system MICROPULS® Everest offers our customers the cutting edge technology of nitriding. It is used in numerous industries, from automotive and contract heat treatment to aviation and wind energy.

ANY QUESTIONS?

RUBIG Heat Treatment combines state-of-the-art technology and in-depth industry knowledge to optimise the finishing of your steel products.

DI David Unterberger

Head of Sales – Heat Treatment