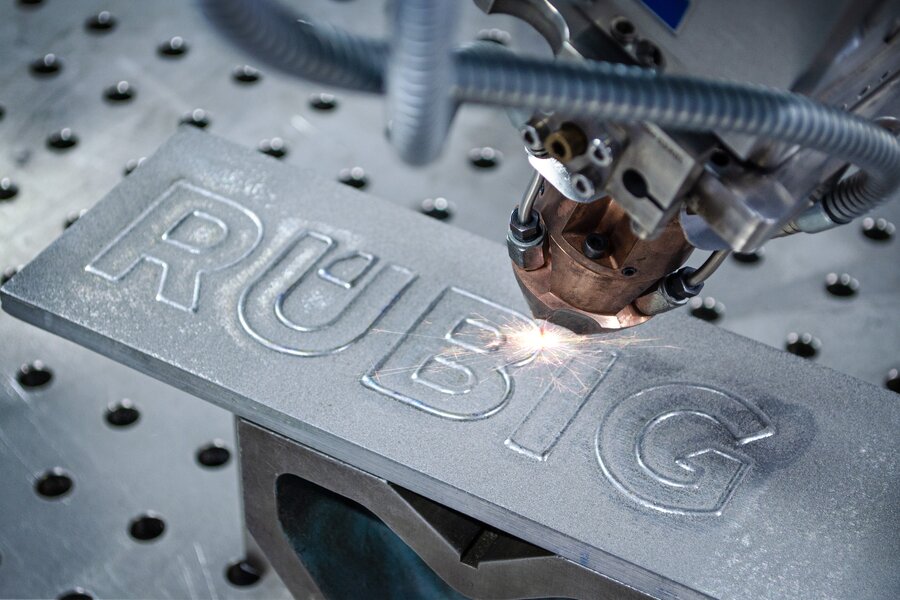

News on Die Forge, Heat Treatment & Industrial Furnaces at RUBIG

Get the latest insights into forging, heat treatment and plant engineering at RUBIG – follow our innovations and stay one step ahead!

The challenges for extruders and injection-molded components are enormous: The mechanical and corrosive stresses of the individual machine components are constantly increasing.

RUBIG Die Forge is expanding its activities in North America and further strengthening its market presence in this strategically important region.

RUBIG adds a powerful analysis tool to its visualization solution, making evaluations more intuitive and streamlining process control.

More precision, less wear: Why nitriding crankshafts and camshafts pays off twice.

CrN coatings protect components from wear, heat and friction – biocompatible, hard and ideal for industry and medical technology.

RUBIG Die Forge is now certified according to ISO 14001:2015 and ISO 45001:2018 – a clear commitment to sustainability, safety, and responsible operations at the Wels site.

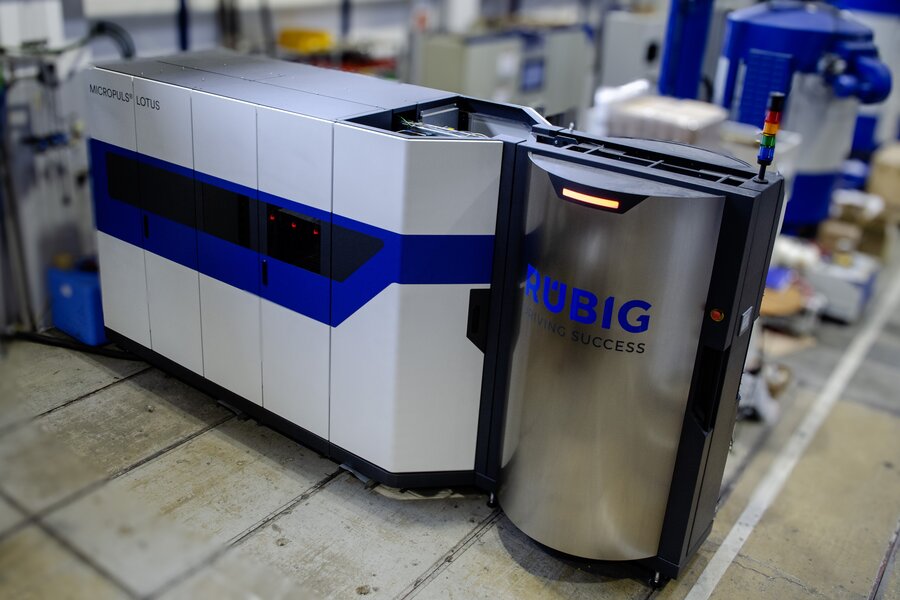

A forging company lowered unit costs, improved flexibility, and reduced supplier dependency with in-house plasma nitriding. The MICROPULS® Everest system paid for itself in just 1.5 years.

Discover how RUBIG extends the service life of forging dies, reduces downtime, and significantly lowers unit costs through innovative nitriding processes – especially plasma nitriding – for more efficient and cost-effective production.

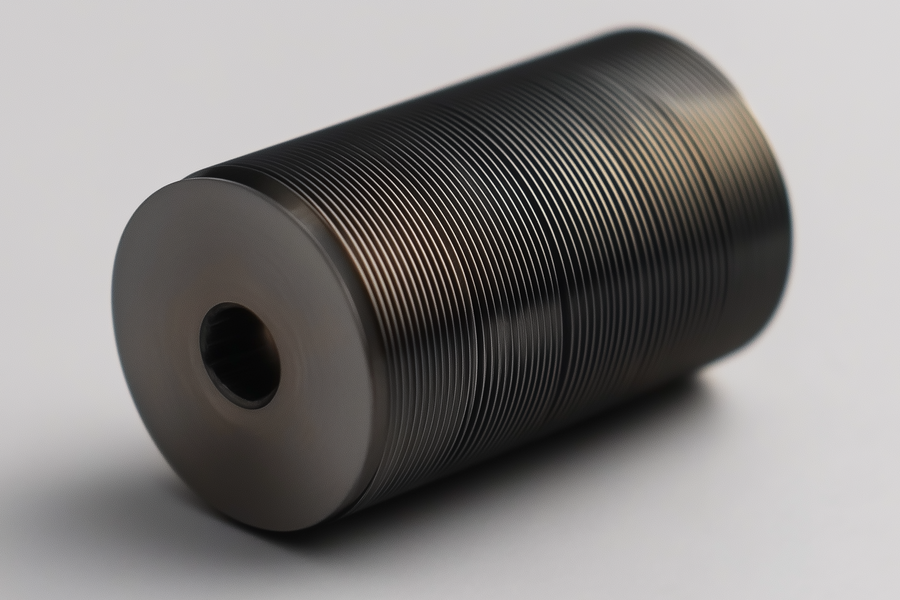

Thread rolling tools are subjected to extreme stresses, and every failure has financial implications. Plasma nitriding is an innovative surface hardening process that specifically reduces wear and significantly increases the service life of your tools. The process is precise, low-distortion, and environmentally friendly – making it ideal for demanding cold forming applications such as thread rolling.

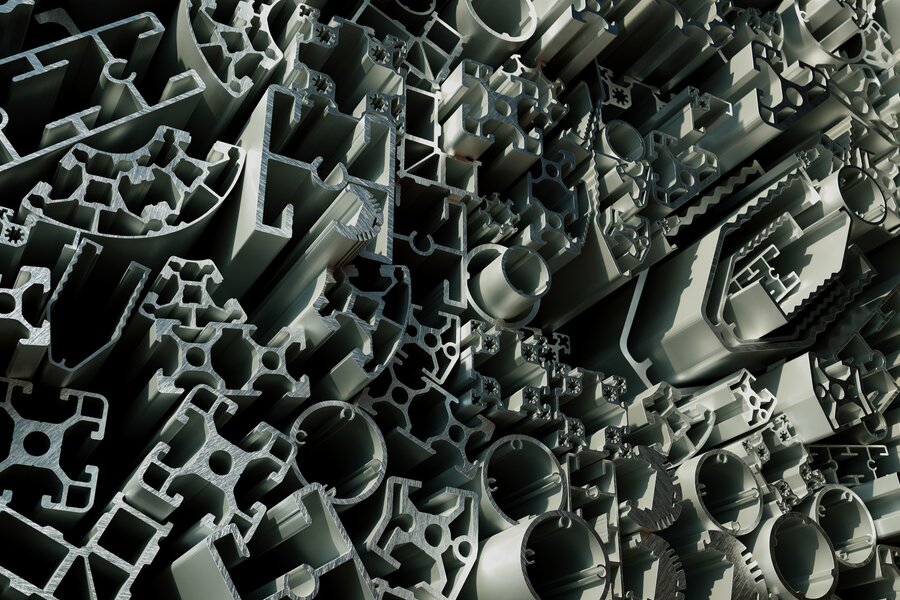

Aluminum extrusion presses aluminum alloys through tools to form complex, lightweight profiles. Thanks to their low density, corrosion resistance, and excellent formability, they are essential in the automotive, mechanical engineering, electrical engineering, and aerospace industries.

An interview with Sebastian Walchshofer, Head of the Automation and Software Department at RUBIG Industrial Furnances.

At the end of 2024, the RÜBIG Group will restructure its management: Bernd Rübig will assume joint leadership with Christian Dipolt,

Technology, man and machine are an unbeatable team! With the RUBIG visualization, these three success factors merge into an ultimate tool for your RUBIG system and transform effective processes into highly efficient processes.

Whether in the automotive, aerospace or mechanical engineering industries, they all benefit from the excellent tribological wear protection of WC/C-DLC coatings.

RUBIG enters new dimensions of surface treatment and offers innovative deep black coatings. With an L value of less than 30 in the L.A.b color space, the deep black coated components look as if they were absorbing the light.

Cost and energy efficient: Laser deposition welding and laser hardening give your components the properties they need.

The RUBIG S-Clip is unique in design and shape and was developed in-house at RUBIG.

Corrosion and wear protection, high surface hardness and low roughness: piston rods for hydraulic cylinders are among the main products of fluid technology that must meet these requirements.

We are excited to share a recent feature from LT1 Privatfernsehen GmbH that highlights the incredible work we do at RUBIG.

RÜBIG received the Julius Award.

RUBIG is very pleased to have a new sales representative on the Industrial Furnaces team: Miguel Garagorri Sistiaga.

RUBIG Elektrokraft has been a reliable partner for electrical installations for over ten years. This year, the company was at the “WeBuild” energy saving fair in Wels for the first time. We talked to Alexander Heitzinger, Managing Director of RUBIG Elektrokraft, about the impressions, the development of Elektrokraft and the future plans.

No results found.