In addition to solid, liquid and gaseous, plasma is the fourth state of matter. It is created by supplying very large amounts of energy to a gas. This can be achieved by heat, radiation or by electrical voltage. The latter is the case with the RUBIG generator.

A plasma generator is needed to perform processes such as PLASNIT®, PLASNIT® C or PLASOX®. Find out more about the functionality of our plasma generator from RUBIG Industrial Furnaces!

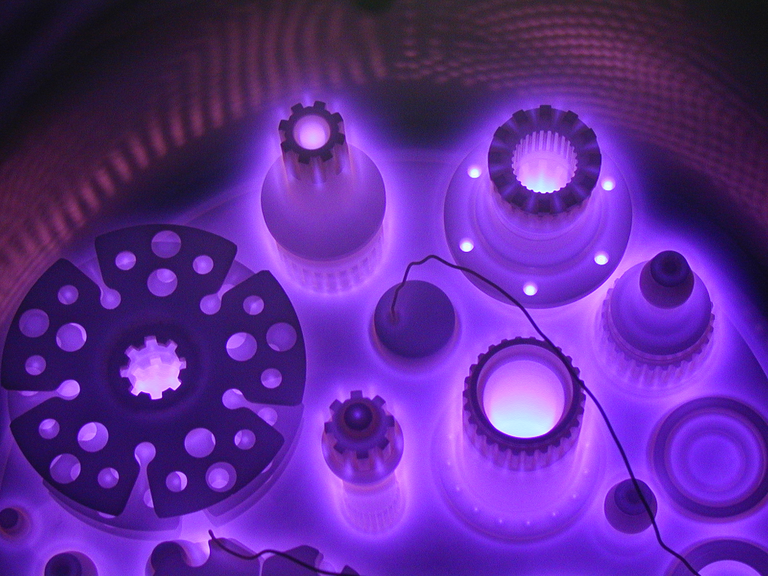

PLASMA IGNITION

The transformation of the process gases by the inverter generator

The process gases (usually hydrogen, nitrogen, argon or methane) become an ionized, conductive gas as soon as a voltage value is exceeded and the plasma is ignited (glow discharge). The generator functions as a voltage converter (inverter) and converts power current or three-phase current into galvanically isolated, rectangular pulsed DC voltage. Only this pulsed output voltage, combined with a pressure range in the maximum two-digit millibar range, makes plasma ignition possible.

MAXIMUM PROCESS FLEXIBILITY

Operating modes and setting options of the RUBIG plasma generator

The system can be operated in either voltage-controlled or current-controlled mode. In the basic package, you can also choose between monopulse, bipolar operation or pure DC (direct current) in each module. The output can also be reversed in polarity, i.e. set positive or negative depending on the specification. Since the pulse length and pause can be individually controlled both in monopulse and bipolar operation, the plasma power can also be set in a controlled manner. Thus, RUBIG plasma generators guarantee the greatest possible process flexibility.

HIGHEST SAFETY STANDARDS

The integrated Arc Detection System in action

The security mechanisms often exceed common industry standards. The integrated Arc Detection System continuously monitors the current and usually shuts down in less than 300 nanoseconds if damage to the batch is threatened by a so-called arc (lightning in the plasma cloud). A detailed protocol enables an exact error analysis and corresponding fine adjustment of the process.

Innovative and Tailor-Made

With over three decades of technological leadership, we develop equipment solutions precisely tailored to your manufacturing processes. Consult with our experts to implement a solution that sustainably optimizes your production.

DI Stefan Haas

Head of Sales - Industrial Furnaces

Application areas

In addition to their reliable, energy-efficient performance, RUBIG generators are also characterized by their modularity. Due to their compact design, they can be quickly integrated into existing production lines. Upgrades at a later date are also no problem.

The main areas of application for the RUBIG plasma generator are:

- Plasma nitriding (with or without subsequent oxidation)

- DLC coating

- PVD coating

- Plasma carburizing

- Magnetron sputtering

- Plasma fine cleaning and sterilization

- Plasma etching

- Pretreatment of plastics (plasma cleaning, activation)

- Surface treatment of non-conductive materials by alternating pulse operation

- Retrofitting of existing nitriding and coating systems (also from other manufacturers)