Industrial furnaces for the highest demands

Equipped with tailor-made heat treatment and coating systems for all possible usage cases.

The Industrial Furnaces division at RUBIG is your competent partner when it comes to the construction of furnaces.

Thanks to our development experience, we produce tailor-made heat treatment plants that are specially tailored to your customer needs.

Industrial furnaces for the highest demands.

Our MICROPULS® technology stands for leading plasma technology in the heat treatment sector. Partners all over the world rely on RUBIG's expertise in plasma nitriding technology.

Our customers benefit from over three decades of technological leadership in the production of heat treatment systems for a wide variety of industries – be it for job-shop heat treatment or fully automated in-house manufacturing operations. Discover how our solutions can optimize your processes!

With our MICROPULS® systems, we offer you innovative heat treatment and coating solutions, tailored to your needs - that's what RUBIG Industrial Furnaces stands for, driven by our powerful, modular and precise MICROPULS® generators, developed in-house by RUBIG.

With a MICROPULS® Everest system, you are opting for the top of nitriding technology.

The MICROPULS® Procoat coating system enables the creation of premium hard coatings.

Innovative DLC coatings from RUBIG: This is what the MICROPULS® Diamond Xtended system stands for. For that little extra in the coating sector.

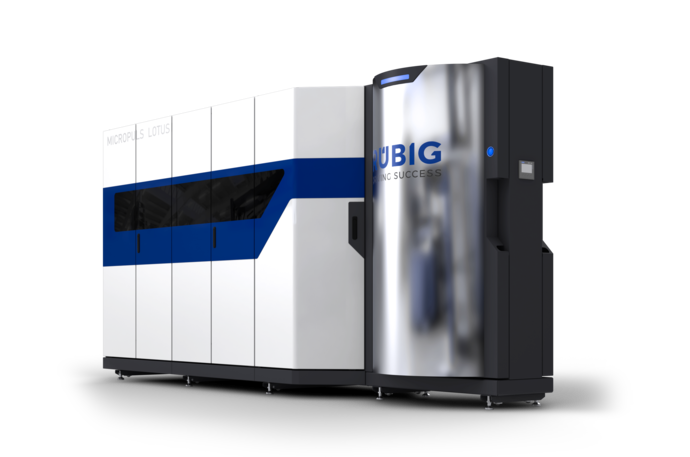

Our MICROPULS® Lotus system lets you benefit from innovative and individual PVD thin-film technology. The perfect addition for perfect surfaces.

The RUBIG MICROPULS® plasma inverter is the heart of every MICROPULS® system. It generates plasma, the fourth state of matter in addition to solid, liquid and gaseous. Plasma is created when enormous amounts of energy are supplied to a gas. This energy can be generated by heat, radiation or, as with our RUBIG generator, by electrical voltage.

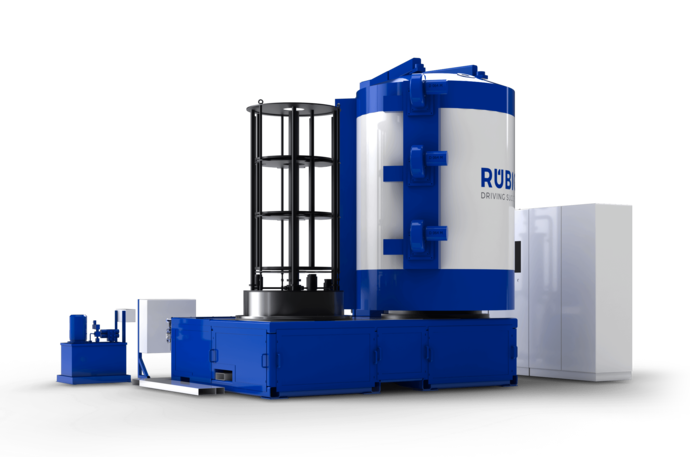

The GASCON technology from RUBIG Industrial Furnaces stands for highly efficient and advanced gas nitriding. The modular systems, which are tailored to customer requirements, impress with their excellent service life and the possibility of regulating by means of a nitration index.

Reach completely new heights and previously unknown areas with the new GASCON K2.

RUBIG underlines its industry leadership with important certifications that guarantee the highest standards in quality, environmental compatibility and safety.