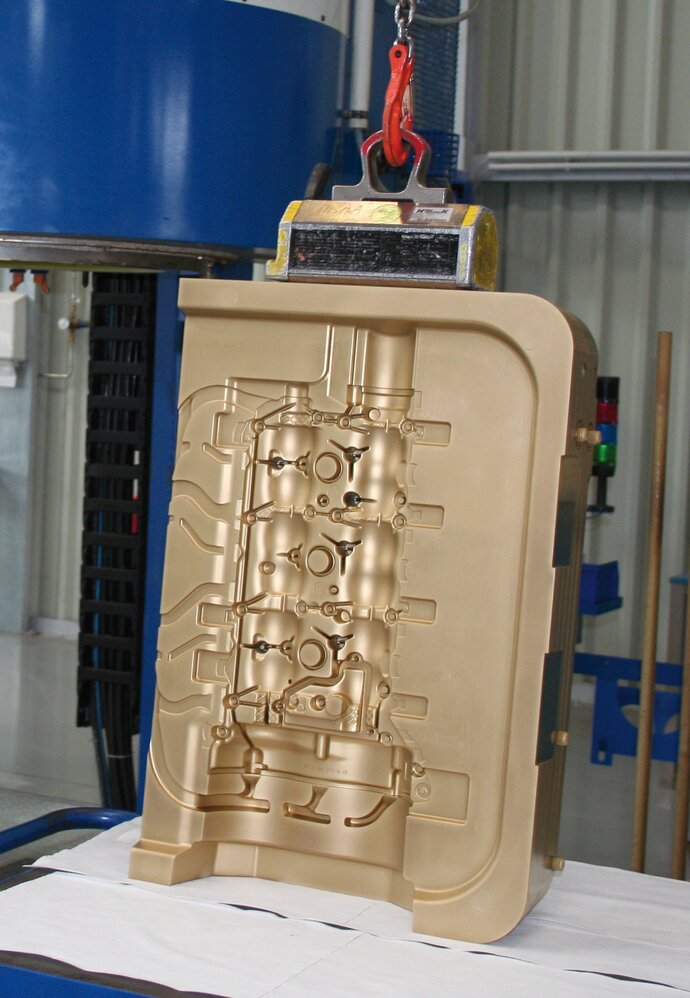

The MICROPULS® Procoat is the optimal system solution in the field of hard coatings - from mold making to component coating.

MICROPULS® Procoat scores with its wide range of applications (multicoating, gradient or nanocomposite coatings and variable coating structure) even for large and complex components and lower treatment temperatures compared to conventional CVD methods. DUPLEX processes enable an all-in-one solution and thus lower unit costs.

With us, modern plant construction meets experience and passion: The MICROPULS® Procoat convinces in many industries, from aluminum die casting and plastic injection molding to machine and tool construction to food processing. Discover the advantages and make an appointment for a consultation today!

| Type | Useful diameter | Useful height | Maximum batch weight |

|---|---|---|---|

| PC 40/60 | 400 mm | 600 mm | 500 kg |

| PC 70/90 | 700 mm | 900 mm | 1250 kg |

| PC 100/150 | 1.000 mm | 1.500 mm | 5000 kg |

| PC 150/180 | 1.500 mm | 1.800 mm | 7500 kg |

| PC 150/210 | 1.500 mm |

2.100 mm |

7500 kg |

All systems are available as SINGLE, DUO or TANDEM systems, as well as laboratory or special sizes.

Innovative and Tailor-Made

With over three decades of technological leadership, we develop equipment solutions precisely tailored to your manufacturing processes. Consult with our experts to implement a solution that sustainably optimizes your production.

DI Stefan Haas

Head of Sales - Industrial Furnaces

PROCESS

Our customers realize the PLASTIT® process with this coating system.

Find out more about the PLASTIT® process here!