Materials engineering

The right process for every challenge.

For a proud 70 years we have been dedicated to the material steel. Our many years of experience in die forging, in the hardening shop and in industrial furnaces form a valuable basis for metal science, material testing and the understanding of metallic components. Heat treatment is a crucial technology in the entire life cycle of a component.

Material production, selection, component planning, design and production are important, but only in combination with the right heat treatment a smooth operation can be ensured. Our comprehensive theoretical knowledge and practical experience make us a competence center for metallic materials.

We ensure that your quality requirements in heat treatment are met in accordance with automotive and aviation standards.

Heat Treatment: RÜBIG GmbH & Co KG

Griesmühlstraße 10

4614 Marchtrenk

AUSTRIA

t: +43 7242 / 660 60

f: +43 7242 / 660 60 3077

ht.office@rubig.com

Billing Address:

RÜBIG GmbH & Co KG

Griesmühlstraße 4

4600 Wels

Office opening hours:

Mon - Thu: 7:00 - 16:00

Fri: 7:00 - 12:30

Acceptance of goods and opening hours:

Mon - Thu: 7:00 - 17:00 o'clock

Fri: 7:00 - 14:30

Sa: by appointment

Sometimes a change of perspective is enough to see more clearly. At RUBIG, we understand that the performance of components depends on many factors. It is only through the right combination of component design, manufacturing method, material and heat treatment that components achieve the resilience and durability they need.

The variety of steel grades and heat treatment processes available enables us to offer tailor-made solutions for a wide variety of requirements. The selection of the right material and the appropriate heat treatment significantly determines whether the required properties for the operational use of a component can be achieved.

Our team at RUBIG Research & Development is working on developing customer-specific processes, scaling up components and transferring them to series production. Because your satisfaction and the success of your components are our top priority.

Personal Consultation

Do you need help with the analysis of your components? Contact us!

Our materials service team is ready to carry out a thorough inspection of your components.

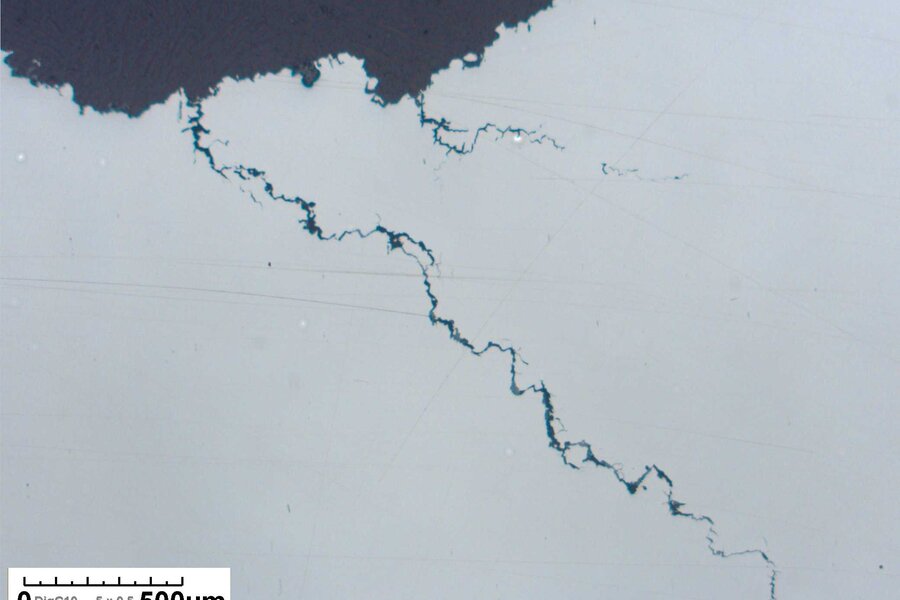

Practical application shows again and again: every mistake that is theoretically possible will eventually occur if nothing is done to fix the causes. It is therefore crucial to systematically identify the causes of errors and to consistently correct them.

Damage is undoubtedly annoying. Nevertheless, it offers the opportunity for a meaningful and targeted improvement, especially if it is accompanied by a systematic failure analysis.

This provides valuable information about the properties of a component that are decisive for its service life and operating conditions. On this basis, targeted improvements can be made to avoid the repetition of errors. Through a systematic failure analysis, unsuitable, impractical or exaggerated measures can be avoided.

We share our comprehensive know-how with you in order to optimize or further develop your components. We support you in finding the ideal combination of material, production and heat treatment – tailored to your specific requirements and the stress situations. Together we will achieve success!

The material examination includes the exact determination of the chemical composition of unknown metallic materials. This is particularly important in case of suspected material mix-up to be discovered during the receiving inspection, to ensure the material delivery quality or to limit the origin of foreign particles.

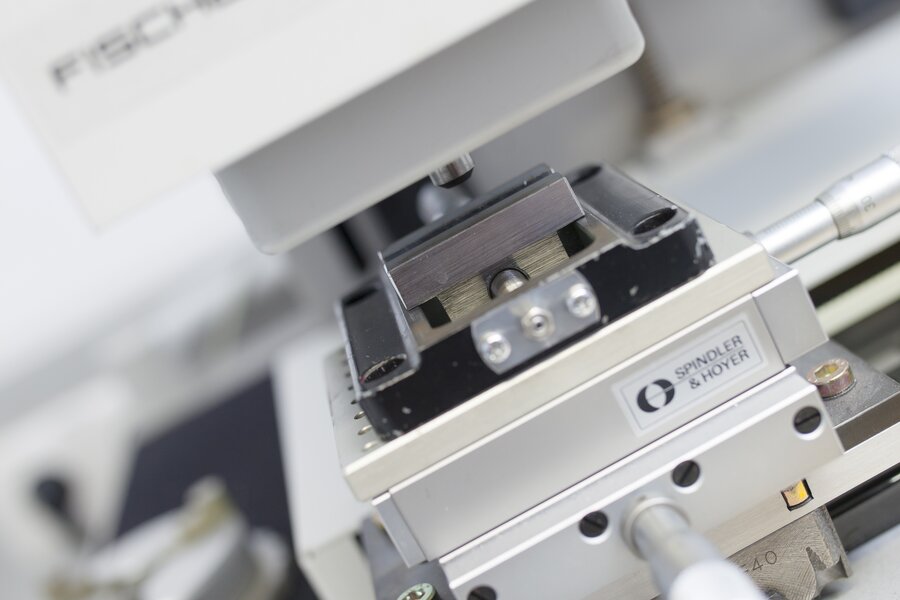

We offer comprehensive hardness tests for metallic components and workpieces, including hardness profile measurements and tests of thin hard coatings by means of an instrumented penetration method. In addition, we also carry out hardness tests on welding joints. For reliable results and quality assurance!

Our qualitative and quantitative microstructure characterization is a decisive means for assessing the basic material properties and the heat treatment condition. Rely on our expertise to gain comprehensive insights into the structure and properties of your materials.

Our X-ray determination of the residual austenite content serves as a quality assessment for heat treatments or as a conformity check to ensure that specified residual austenite limits have been exceeded. Rely on our precise analysis to achieve the highest quality standards.

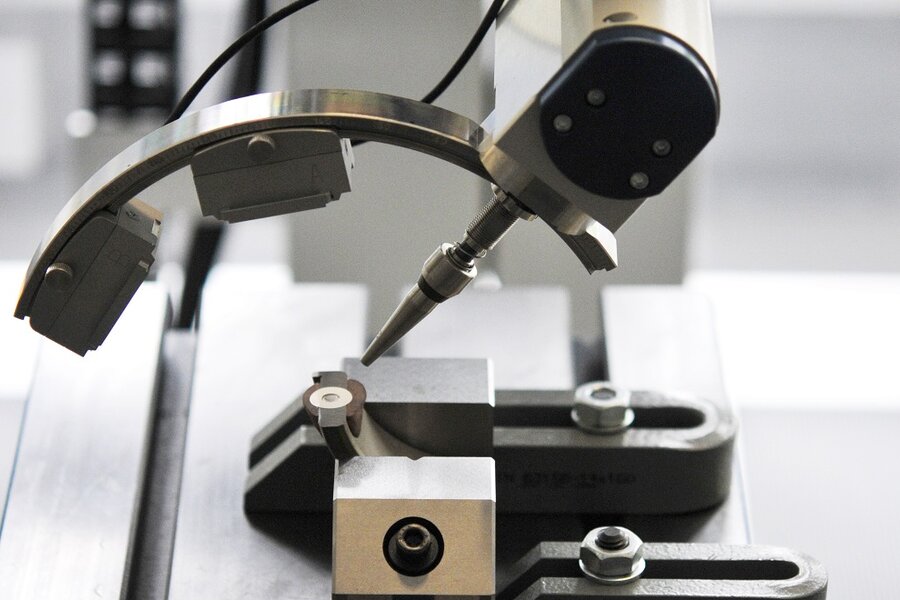

Our X-ray measurement of residual stress or residual stress curves in component edge zones provides important insights into load capacity, fatigue strength and influences from mechanical or electrical discharge machining.

Our expertise includes the assessment of corrosion damage and the determination of corrosion causes. Based on these findings, we derive prevention measures to reduce the corrosion sensitivity of your components. In addition, we carry out corrosion tests to determine the corrosion resistance of your components.

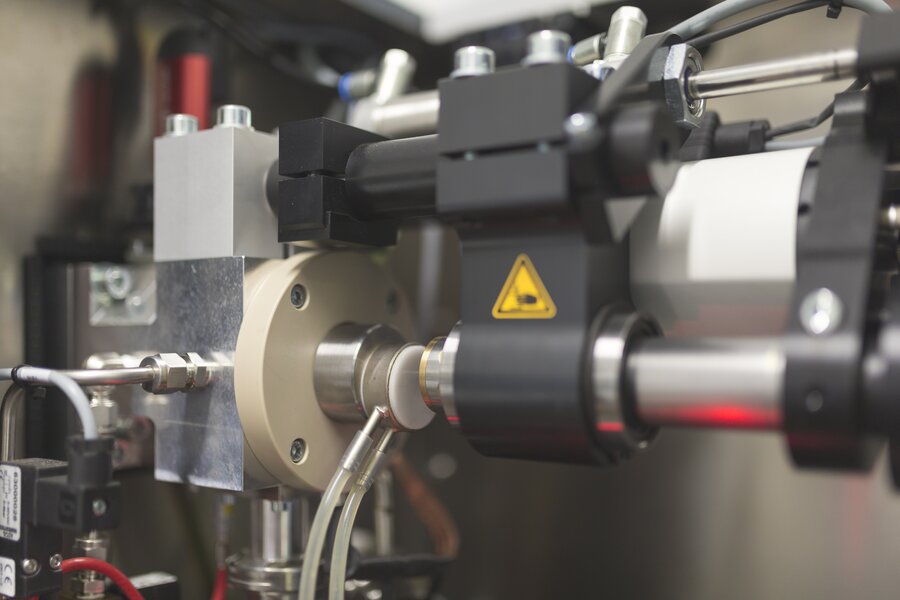

The tensile test is one of the most frequently used mechanical-technological test methods. It offers a thorough and comprehensive analysis of the material behavior under uniaxial, quasi-static loading. The experiments take place on round samples at room temperature.

Our seminars offer a well-founded transfer of knowledge and practice-oriented experience in the field of heat treatment. They are specifically aimed at designers, manufacturers and work preparers who either have no experience with this technology yet or would like to deepen their existing knowledge.