Challenges for extruders and injection molding components are enormous: Mechanical and corrosive stresses on individual machine components continue to increase. Especially ex-truder screws, spindles, shafts and comparable parts are affected. High servicing costs and down-times are the result.

Nitriding of injection molding components

Nitriding offers a perfect solution in this case. It extends wear resistance and consequently service life of components, without negatively impacting corrosion resistance.

Depending on application and request, plasma as well as gas nitriding are used, whereas PLASNIT® plasma nitriding is preferred in terms of environmental friendliness and safety issues. (You can find some more details to this topic in the attached link collection!)

With component lengths of up to 8 m, also size of the treated parts is a big issue for manu-facturers as well as commercial heat treaters. Nevertheless, also here RÜBIG offers taylor-made solutions. Either in serving as commercial heat treater in it’s Austria’s headquarters, or as global furnace supplier.

Nitriding in practice – ENGEL St. Valentin (Austria)

ENGEL is an Austrian manufacturer of plastic injection molding machines, which are used in the automotive & mobility, packaging, consumer electronics, medical technology and technical injection molding.

Ready-to-run system solutions are just as much part of the product portfolio as customized special automations. The integration of all individual components by mechanics as well as control-mechanisms results in compact solutions whose function is optimized in terms of performance and user-friendliness.

Following its motto "Green is more than a colour", ENGEL is also a pioneer when it comes to sustainability and, with the use of advanced technologies, sets decisive standards for more environmental awareness within manufacturing.

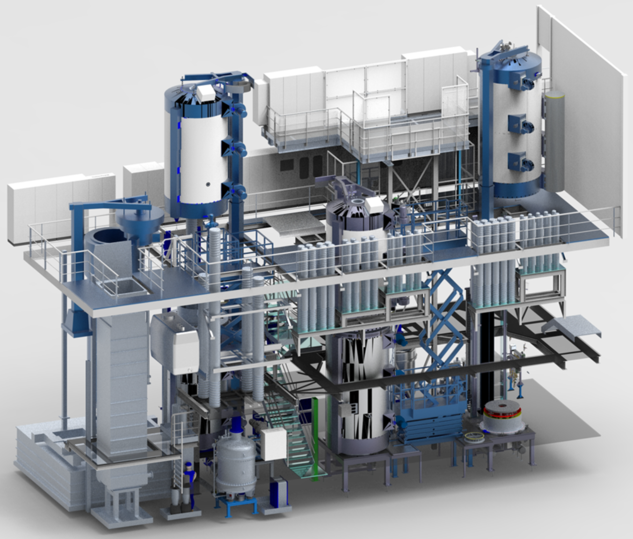

© Image source: ENGEL

About the project

Components of ENGEL injection molding machines have to withstand very specific re-quirements. Protection against wear and corrosion is particularly important, but appearance also plays a role for visible components. A flexible overall concept for heat treatment, their corresponding pre-treatments, as well as the complete component handling had to be worked out and supplied.

About the solution

- The special component geometry (up to 7.5 m / 24.5 ft in length and total loading weights of up to 30 tons / 66000 lbs) required a very specific concept in terms of furnace design, handling of the components and rapid cooling of this mass.

- In order to maintain maximum flexibility, the first nitriding systems were designed in a way that gas nitriding, plasma nitriding as well as oxidation processes could be performed.

- For a perfect condition of the components before nitriding, also machines for water-based cleaning, tempering and annealing were delivered.

- While the entire process development was carried out on site at ENGEL, the RCC (RÜBIG Competence Center) took over all the laboratory analysis.

Today, this nitriding center consists of a total of 8 systems for cleaning, tempering, annealing and nitriding, with plasma nitriding being the preferred technology in terms of sustainability.

More articles at a glance

Would you like to learn more?

With more than 30 years of experience, we design plant solutions that integrate seamlessly into your manufacturing process. Talk to our expert to take your production efficiency to the next level—sustainably and long term.

Contact DI Stefan Haas.

DI Stefan Haas

Head of Sales - Industrial Furnaces