Convenient handling, always constant dosing, increasing the density and avoiding dust – all this makes the use of pellets so popular. Therefore, pellet production is all about efficiency, reproducibility and continuously high quality. Exactly these properties must also be fulfilled by the pellet die itself and the associated machine.

Nitriding in pellet production

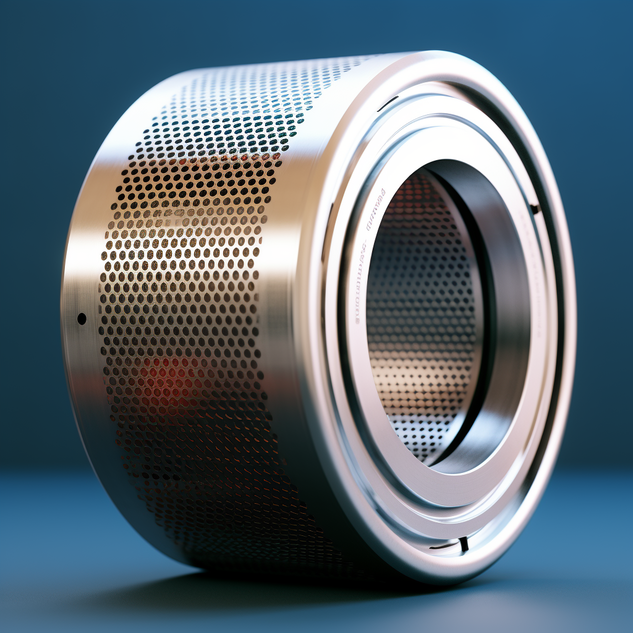

Pellet dies and nitriding – useful?

Absolutely! Good dies are characterized by a long service life and durability of the respective surface. These are influenced not only by their production, they are also significantly improved by better resistance to wear and corrosion.

The surfaces of plasma nitrided dies show improved wear resistance, have better friction and sliding properties and higher fatigue strength values. Due to the comparatively low distortion during plasma nitriding, the die can be completely machined before the heat treatment and then used immediately.

There are few restrictions on the choice of materials, but stainless steels, heat-treated steels and nitrided steels are particularly predestined for plasma nitriding.

Pellets everywhere you look

The continuous increase in efficiency in recent decades has contributed to the fact that pellets are used in almost all industries.

- Wood, plant fibres or sewage sludge are processed into biomass pellets in order to be fed to the combustion process fully automated and unmanned.

- Concentrated feed, hay, bedding or bran can be transported, stored and eventually be fed more efficiently by pelletizing. Unnecessary dust is avoided as well.

- The use of pellets makes industrial handling of plastics, iron ore or textiles even more efficient.

- Tea extract, coffee, hops or dextrose are just a few examples where pelletizing is popular in order to produce reproducible taste results.

- Even in the production of dietary supplements or antibiotics, pellets are used for pre-dosing.

Depending on the industry, a die has to struggle with many influencing factors. Special raw materials, residual moisture, binders, molasses as well as fiber-rich or silica-containing ingredients put a very special strain on the molds.

One nitration, many components

Even if flat or ring dies are the real stars of a pellet press, there are still numerous other components in these systems that are also nitrided. Rollers, screws or screen plates are just a few examples.

Everything from a single source

At RUBIG you can not only contract harden your components, we also offer tailor-made heat treatment systems for sale. Thanks to decades of experience in plant construction, we know what is important. Discover our premium systems and rethink nitriding.

Would you like to find out more? Then contact GE (FH) Stefan Haas!