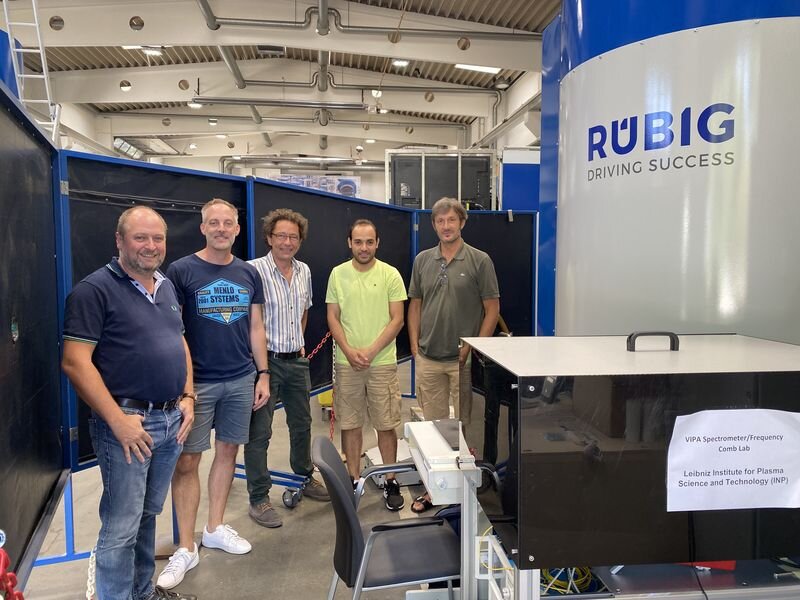

The absolute priority at RUBIG is constant further development in order to always be at the cutting edge of technology. For this purpose, the bundling of competencies is excellently suited to always be one armlength ahead. With Norbert Lang, Ibrahim Sadiek and Uwe Macherius from the INP in Greifswald, as well as Stefan Matern from Menlo Systems GmbH, we have found the perfect partners to carry out a measurement campaign as part of the InPro-F project (Innovative plasma nitriding by dynamic process control using optical frequency combs). Species produced in the plasma are measured and analyzed by means of lasers.

Innovative plasma nitriding through dynamic process control by means of optical frequency combs

Details of the research project

Laser absorption spectroscopy in the infrared spectral range is a suitable method for optical process control in plasma nitriding. Conventional spectroscopy systems would be too complex and too expensive for use in industrial plasma nitration, since many laser sources would be required to measure the process-relevant gas and molecule concentrations. By contrast, with the help of an optical frequency comb, which replaces many thousands of lasers, concentrations of this species can be detected simultaneously and provided to a process control.

However, the conditions in industrial plasma nitriding place high demands on compactness, robustness and resolving power, among other things. New techniques and innovative components of a frequency comb-based spectroscopy system required for this are to be developed as part of the joint project InPro-F. In the joint project, SMEs Menlo Systems GmbH and neoplas control GmbH will carry out the necessary developments together with the Leibniz Institute for Plasma Research and Technology e. V. as an academic partner.

As a leading manufacturer of nitriding systems, RUBIG GmbH & Co. KG formulates the corresponding requirements, accompanies the developments and provides both the industrial expertise and nitriding systems for developments, tests and verifications. The project goal is a demonstrator of a compact and robust frequency comb system that can be used in industrial plasma nitriding processes, which will allow in-situ process control and thus make the commercial and ecological savings potential of this process accessible.

A new sales market with long-term growth potential will open up for the SMEs, and the associated partner will be able to consolidate its market leadership.