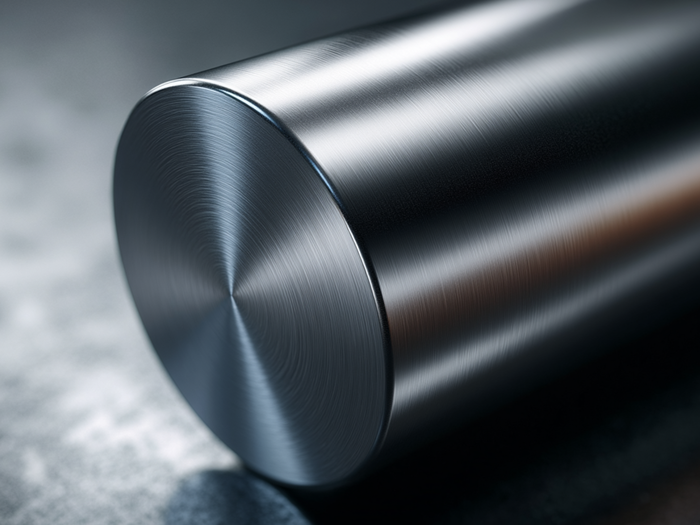

CrN Coatings – Chromium Nitride for Maximum Wear Protection

CrN (chromium nitride) is a metallic‑grey PVD coating distinguished by high hardness, superior wear resistance and outstanding thermal stability. At only a few microns thick, it markedly increases component service life and performance without altering part geometry.

Key Benefits of CrN Coatings:

- Low coefficient of friction – ideal for tribological applications

- High temperature and oxidation resistance

- Excellent adhesion on steel, stainless steel and non‑ferrous alloys

- Matte metallic finish with minimal light reflection

- Verified biocompatibility for medical devices (ISO 10993) Typical Applications

Typical Applications

Medical Technology

For makers of scalpels, forceps, and implant instruments, CrN enhances patient safety. The coating remains corrosion‑resistant through countless autoclave cycles, is easy to sterilise, and cuts the risk of allergic reactions caused by metal‑ion release.

- Surgical instruments

- Prevents nickel release from stainless steel

- Biocompatible per ISO 10993

Plastics Industry

In plastics processing, CrN drastically lowers tool wear and minimises unplanned downtime. Its chemically inert, ultra‑smooth surface prevents material build‑up on demanding polymers (PVC, PC, PA, and more), shortens cycle times, and boosts part quality.

- Injection‑moulding tools, cutting edges and ejector pins

- Optional CrO top layer reduces build‑up and deposits

- Longer tool life, fewer cleaning cycles, higher process reliability

Mechanical Engineering & General Industry

Whether piston rods, bearing bushes, or valve components, CrN elevates surface hardness, reduces lubricant consumption, and prolongs service life—even under abrasive or rapidly changing temperatures. The result: higher equipment availability and reduced total operating costs.

- Highly loaded sliding and guide elements

- Protection against frictional wear, corrosion and thermal stress

- Extended maintenance intervals and component lifetime

CrN Coatings by RUBIG – Your Competitive Advantage

Fewer residues, higher process reliability and consistent quality – RUBIG CrN pays off.

Get personal advice now on the right CrN coating solution for your application.

DI Dr. Christian Dipolt MBA

Managing Director RUBIG Technology