Forgings by RUBIG – Die Forge from Austria

more than 75 years of experience | Innovative & economical |

Series production possible | Custom forms

Get a quote Contact us now

1. INQUIRY & CONSULTATION

We review your drawings or CAD data and propose forge-appropriate design options.

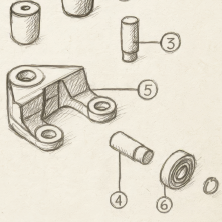

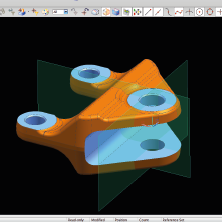

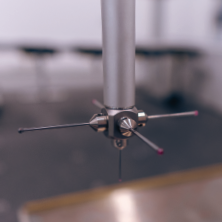

2. DESIGN & 3D MODEL

Creation of 3D models and FEA (FEM) analyses Development of all tools and fixtures.

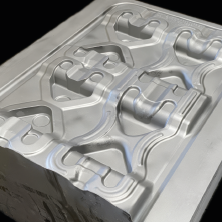

3. TOOL & DIE MAKING

In-house, state-of-theart toolmaking—ensuring consistently high series quality.

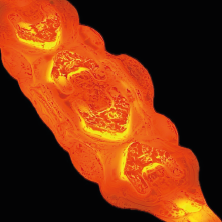

4. DIE FORGING

Hot forming on forging hammers—with documented in-process quality assurance.

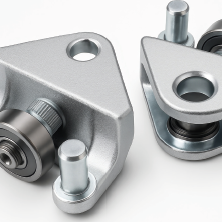

5. MACHINING

Precision CNC milling and turning—threads and mating surfaces as required.

6. HEAT TREATMENT

Hardening, quenching & tempering, annealing, or nitriding—matched to the material and function.

7. ASSEMBLY

Module assembly or welded assemblies to customer specification.

8. QUALITY CONTROL

Crack detection, dimensional checks, documentation, and certification—for maximum process reliability.

for Forged Part Development

Quality Management System:

ISO 9001:2015

Welding Quality Requirements:

EN ISO 3834-2:2021

Environmental Management:

ISO 14001:2015

Occupational Health & Safety Management:

ISO 45001:2018

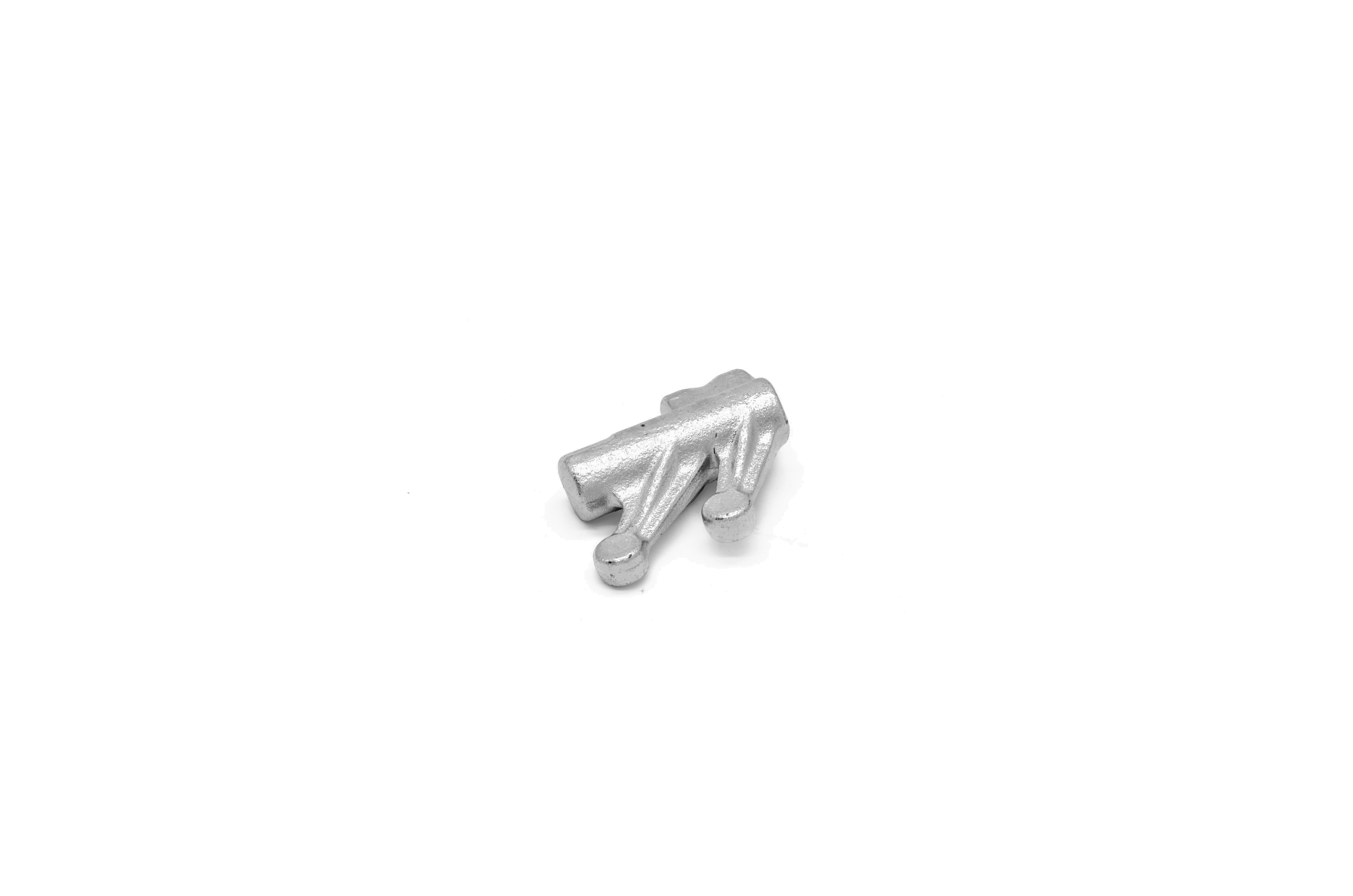

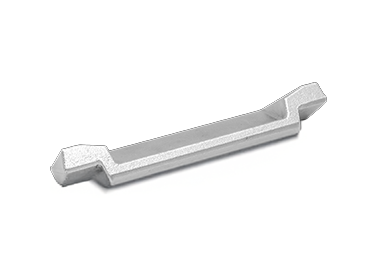

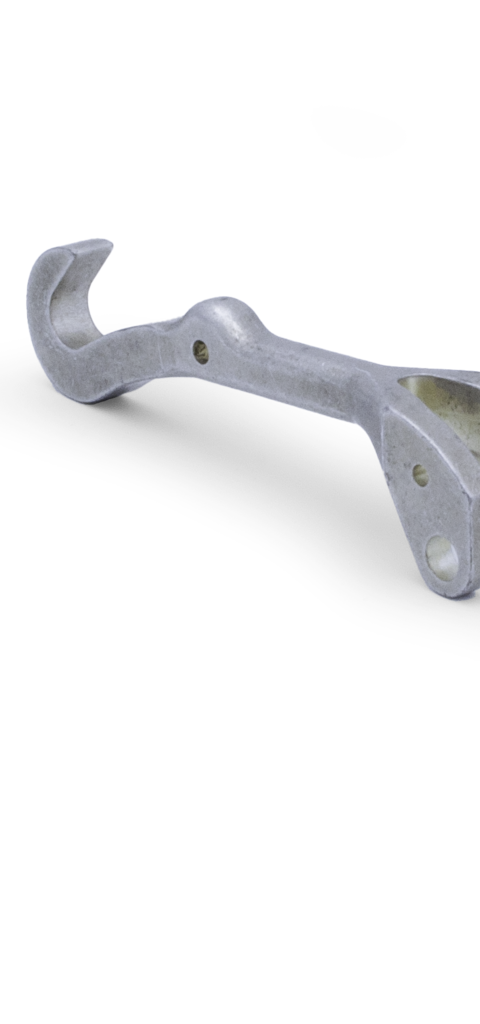

Closed-die forging enables the reliable production of complex components with optimized fiber flow and microstructure.

We support customers with our experience and know-how—from the development phase and material selection through to forge-friendly component design. Inhouse, state-of-the-art toolmaking is the foundation for outstanding quality, ensuring absolute confidentiality and high flexibility throughout development.

| Materials: | structural steels, case-hardening and tempering steels, stainless steels |

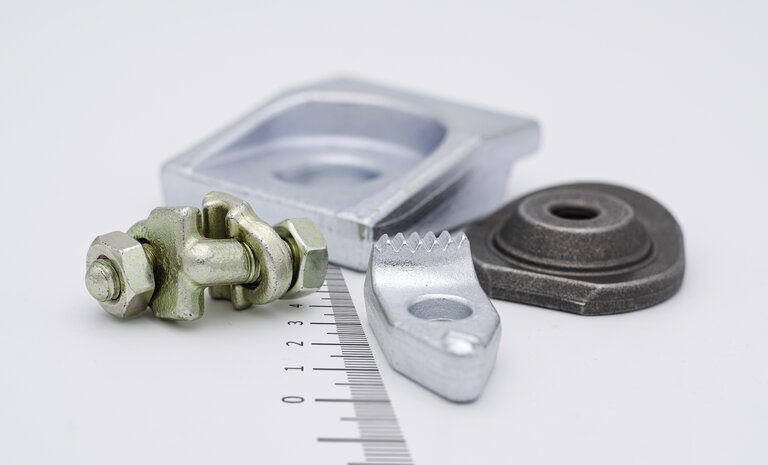

| Weight range: | from 0.010 kg to 4.5 kg |

| Heat treatment: | quenching & tempering, normalizing, case hardening |

| Machining: | CNC turning and milling centers up to five axes |

| Surface treatment: | electroplating and KTL (e-coat) |

| Testing: | 3D coordinate metrology, crack detection, and documentation |

AGRICULTURAL ENGINEERING

MECHANICAL ENGINEERING

AUTOMOTIVE

RAILWAY ENGINEERING

CONSTRUCTION

AND MORE

RUBIG sets standards in the agricultural industry with innovative forging technology, drive systems, and conveying solutions. Our durable forgings — from robust tools and versatile lynch pins to high-strength machine components — are specifically designed to meet the demands of modern agriculture. With our expertise in machining and surface finishing, we enhance the efficiency and longevity of your agricultural equipment and provide optimal support for your processes.

RUBIG drives mechanical engineering forward with custom-forged components and precise machining solutions. Our innovative drive and conveying technologies, combined with our expertise in fastening technology, increase the performance and reliability of your machines and systems — ensuring your competitiveness in the industry.

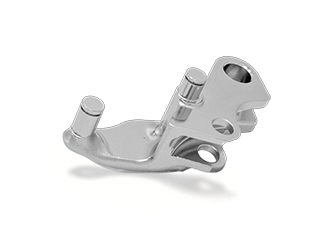

RUBIG supports the automotive industry with advanced forging and machining solutions. Our components for chassis and drivetrain systems set new standards in safety and performance, contributing to increased efficiency and reliability in modern vehicles.

RUBIG manufactures high-quality drop-forged components for railway applications.

Through precise manufacturing, state-of-the-art equipment, and decades of experience, RUBIG produces components that meet the industry’s highest safety and quality standards. The custom-engineered parts are used in rolling stock applications – such as door, brake, and coupling systems, as well as gangways between cars. RUBIG forged components are also reliably used in track infrastructure.

Whether for safety-critical components, fastening elements, or structural parts – RUBIG stands for quality, precision, and cost efficiency in modern railway technology.

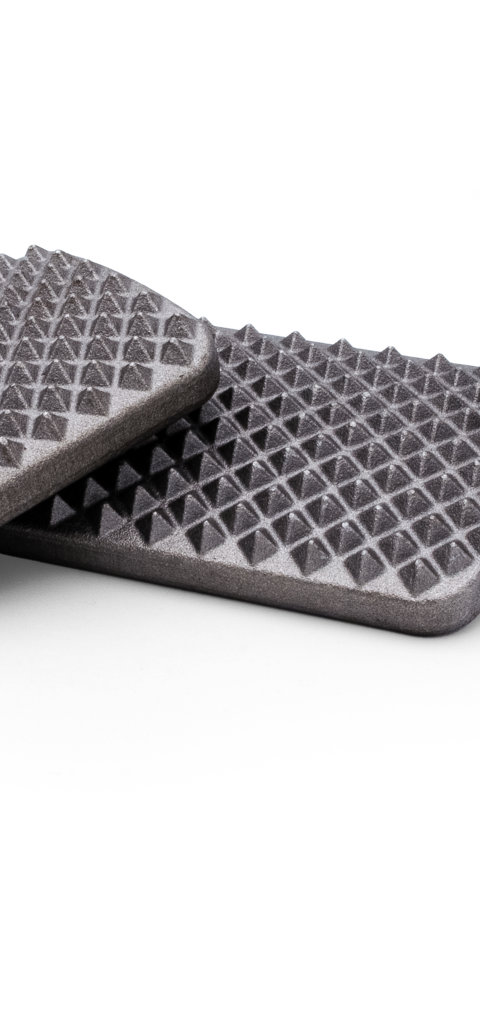

RUBIG supplies robust and precise drop-forged parts for a wide range of applications in the construction industry. Whether connecting elements, anchors, brackets, or safety-critical structural components – our forged parts stand out for their high strength, durability, and dimensional accuracy. Using state-of-the-art manufacturing technologies and extensive know-how, we produce components that perform reliably even under extreme conditions.

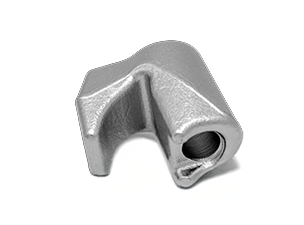

With almost 80 years of experience, RUBIG Die Forge in Austria delivers high-quality forged parts ranging from 0.01 kg to around 5 kg. From the first sketch to final machining, customers receive everything from a single source – including toolmaking, mechanical processing, and heat treatment at RUBIG Heat Treatment.

Certified quality according to ISO 9001:2015 and flexible order handling, even for framework contracts with smaller batch sizes, ensure installation-ready, precise components with outstanding repeatability.

Centralized production in Austria optimizes logistics and guarantees short lead times for coated, heat-treated, and fully machined parts.

It is no coincidence that they are used, for example, in racing engines, where connecting rods and rocker arms forged by RUBIG withstand extreme loads, or on automobile cranes, where a safety linchpin from RUBIG fixes the cable pulley at the top of the boom.

RUBIG manufactures series from a few hundred parts to over 100,000 pieces and can thus supply both small and medium-sized enterprises as well as internationally active corporations.

You too can rely on more than 70 years of experience of RUBIG Die Forge! We are looking forward to your inquiry.

The high-quality forgings from RUBIG are produced reliably in a cost-effective series production, starting with forging-compatible design and transition of the design drawing or sketch. They are optimized in form and function, economical and flexible. The range of processed materials ranges from simple structural steel to case-hardening and tempering steels to stainless steels.

The production facilities of RUBIG Die Forge are designed for the efficient production and further processing of forged parts from 10 grams to 3 kg per piece. Thanks to constantly evolving production methods, the permissible standard tolerances can be significantly undercut. Thus, rework is reduced or eliminated altogether.

Forged parts assembly-ready

From Austria - customised forgings that fit your requirements exactly. Talk to our experts and realise your idea!

Head of Sales

The forged parts can be further mechanically machined, turned, welded, pre-assembled, heat treated or surface finished. Thus the parts can reach the customer ready for installation. Multifunctional turning-drilling-milling centers are used for the production of complex components.

By interpolating up to five axes, every geometric contour can be processed efficiently with maximum precision. The design and manufacture of the required clamping devices are carried out in-house.