Simple is easy – at RUBIG we are specialists for sophisticated customer solutions. RUBIG Industrial Furnaces has developed a tailor-made concept for ENGEL, an Austrian manufacturer of plastic injection molding machines.

Nitriding in practice – Best practice example ENGEL

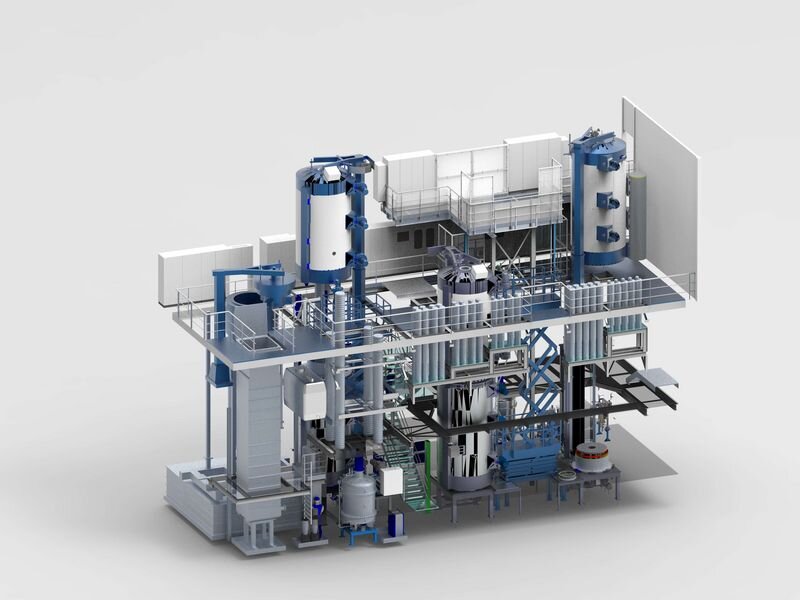

The challenge: The nitriding systems must have a total batching weight of max. 30 tons and be able to handle components up to 7.5 m in length. The customer's request: a concept for a heat treatment system that is as flexible as possible, including the corresponding pretreatments as well as the complete component handling.

Especially the dimensions and the associated plant design presented the engineers with a challenge. In order to ensure maximum flexibility, the first nitriding plants were designed in such a way that both gas nitriding, plasma nitriding and oxidation processes can be carried out. For the perfect component condition before nitriding, the scope of delivery also included systems for water-based cleaning, tempering and annealing. While the complete process development was carried out on site at ENGEL, the RUBIG Competence Center took over the laboratory evaluations of the heat treatment results. This ensured maximum customer satisfaction.

Meanwhile, the ENGEL Nitrierzentrum has eight RUBIG furnaces.