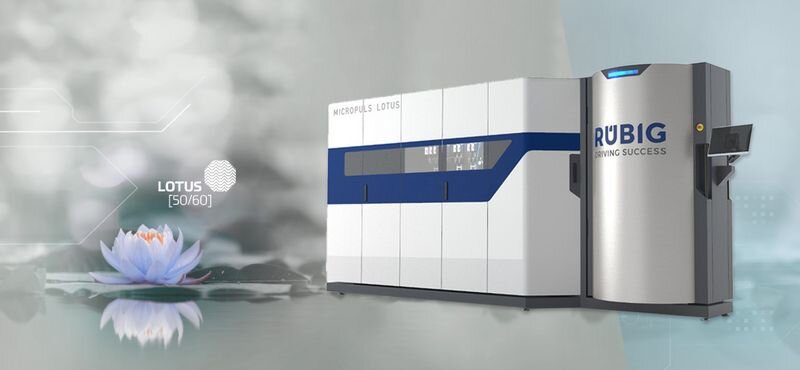

What does the lotus flower have in common with this new product at RUBIG? The lotus flower has special surface properties that protect it from external influences. With the brand new PVD technology "MICROPULS® Lotus", such protective and improving surface properties can be recreated.

The RUBIG Group is expanding its range of coatings and systems with PVD!

RUBIG will continue to remain true to its motto "everything from a single source": customers benefit from joint process development and as a result have the opportunity to make use of the coating service or to purchase a system especially designed for their needs.

What is PVD?

PVD, i.e. Physical Vapor Deposition, is a coating technology for the production of metal-based hard coatings using metal vapor. This vapor can react with gases and forms a thin coating on components with improved wear protection. In addition, surfaces can be produced to improve corrosion and electrical properties as well as with decorative and optical properties. Since the coating temperature covers a wide range of room temperatures up to 500 °C, the treatment of metals, ceramics, glass or plastic is possible.

How is this coating used in practice?

In the automotive sector PVD offers an elegant approach to reduce friction between moving parts. Surface properties such as the mechanical wear resistance and reduced friction of the treated components are enormously improved with this method. PVD coatings also ensure a perfect look with a long service life in the interior and on body components. Compared to many conventional surface finishes, PVD is to be regarded as an environmentally friendly process.

For tools for forming technology the hardness properties of the PVD coating improve the protection against wear corrosion and adhesions.

The consumer goods industry has realized the advantages of these coatings as well. These include, above all, the visual and aesthetic diversity as well as the longevity of PVD. The range of applications ranges from wristwatches and faucets to door handles.

PVD coatings are available on interior and exterior elements in many different colors such as gold, brass, stainless steel, nickel and black/anthracite. By applying copper coatings, components can even obtain antibacterial properties.

RUBIG plant technology at the highest level

A MICROPULS® Lotus system impresses with its compact design and the individually adjustable process parameters. Thanks to magnetron sputtering technology we can create perfectly smooth and homogeneous coatings. Droplets are a thing of the past.