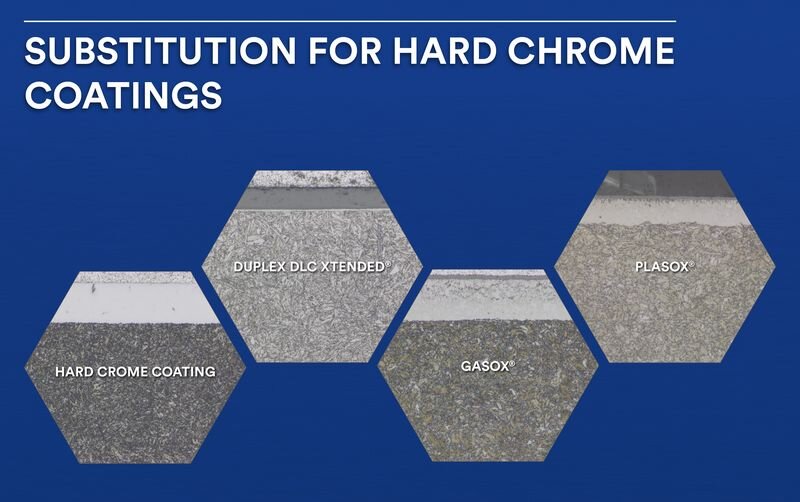

Many industries, including hydraulic cylinder manufacturers, have to adjust to the EU-ban on chromium VI. The RUBIG Group worked on a suitable replacement for hard chrome coatings since quite some time. The RUBIG Competence Center and its R&D team have achieved impressive results in terms of tribology and corrosion in cooperation with RUBIG Industrial Furnaces and RUBIG Heat Treatment. Typical requirements for hard chrome coatings can be achieved or exceeded with the DLC Xtended, GasOX and PlasOX processes that have been further developed especially for this application.

Replacement of hard chrome with RUBIG technology

25.10.2021

In addition to increased environmental friendliness, customers benefit from a corresponding process development for heat treatment on a wage basis as well as from complete solutions with corresponding plant concepts that can be individualized according to customer requirements.

RUBIG offers the following processes as a replacement for hard chrome coatings:

Duplex Coating - DLC Xtended® (Corrosion resistance in the neutral salt spray test up to 500h)

- PACVD-System for coating complex geometries

- Combination process of plasma nitriding and DLC coating

- DLC with excellent features

- Corrosion

- Wear resistance

- Cleanability

- low adhesion of sand and dirt

Nitration and post-oxidation processes (corrosion resistance in the neutral salt spray test up to 120h)

- For nitriding steels (42CrMo4, 31CrMoV9, AISI 4140 or similar)

- Transformation of the surface into a ceramic coating (Fe-N combination) and iron oxide (Fe-O combination)

- Diffusion coating up to 0.6 mm deep with higher hardness and compressive residual stresses

For more information, please contact RUBIG Industrial Furnaces or RUBIG Heat Treatment.