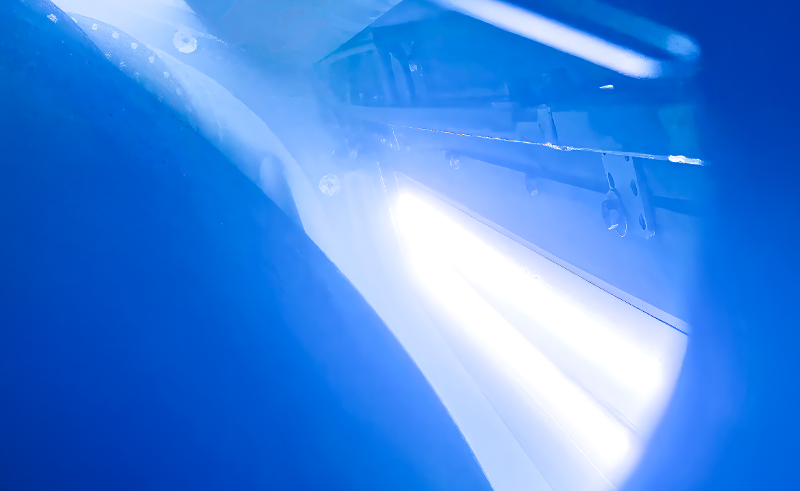

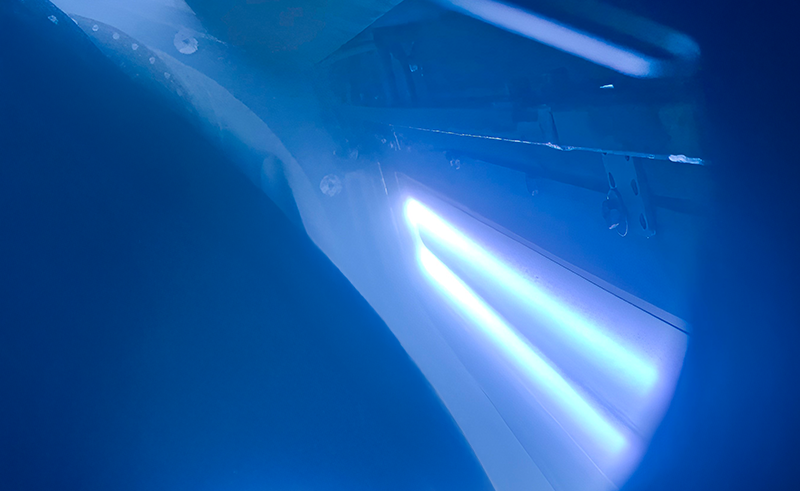

HiPIMS:

high-performance PVD coatings

Ionization levels above 90% deliver harder, denser, ultra-smooth films — ideal for cutting and forming tools.

RUBIG is expanding its PVD portfolio with HiPIMS (High Power Impulse Magnetron Sputtering) high-performance PVD coatings – a state-of-the-art sub-variant of magnetron sputtering. The core: a latest-generation HiPIMS generator delivers pulse currents of up to 1000 A at 1200 V. The extremely high plasma density increases the ionization degree of the sputtered species to over 90% – comparable to arc evaporation, yet with very few defects. The result is very smooth surfaces and highly densified, hard coating systems with excellent wear and corrosion protection.

In HiPIMS PVD coatings, the sputter targets are pulsed with very high power for short periods. This generates a plasma with an exceptionally high ion content. The ionized coating material is precisely accelerated toward the workpiece, resulting in:

HiPIMS is regarded worldwide as the state of the art for demanding hard and functional coatings. In combination with a next-generation power supply, we unlock a broad parameter window: from adhesion-optimized interlayers through ultra-hard tribological coatings to low-friction top layers—precisely tailored to your substrate and process.

From precision parts to tooling: next-generation HiPIMS/PVD.

Get advice on high-performance PVD coatings: better adhesion, smoother surfaces, longer tool life.

Questions about HiPIMS/PVD? We’re here to help!

Managing Director RUBIG Technology

TiN is the classic golden PVD coating for tooling: proven, versatile, and cost-effective. With HiPIMS, TiN delivers a clear performance boost—denser microstructure, fewer defects, and a much smoother surface.

Hardness: Standard TiN vs. HiPIMS TiN

The coating properties stated were achieved under ideal deposition conditions. Depending on surface condition, component size, substrate material, and other process factors, properties on the actual part may differ.