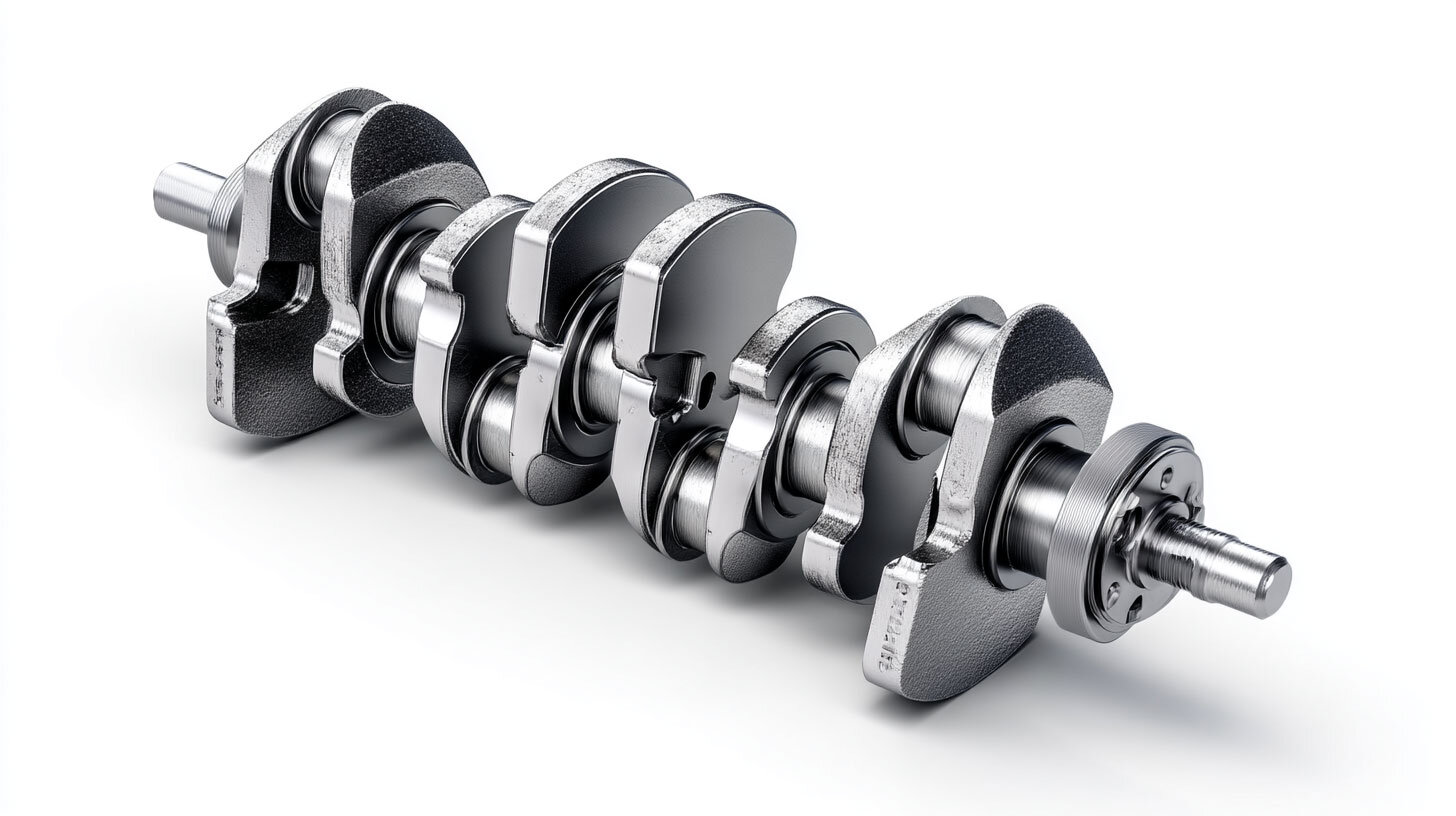

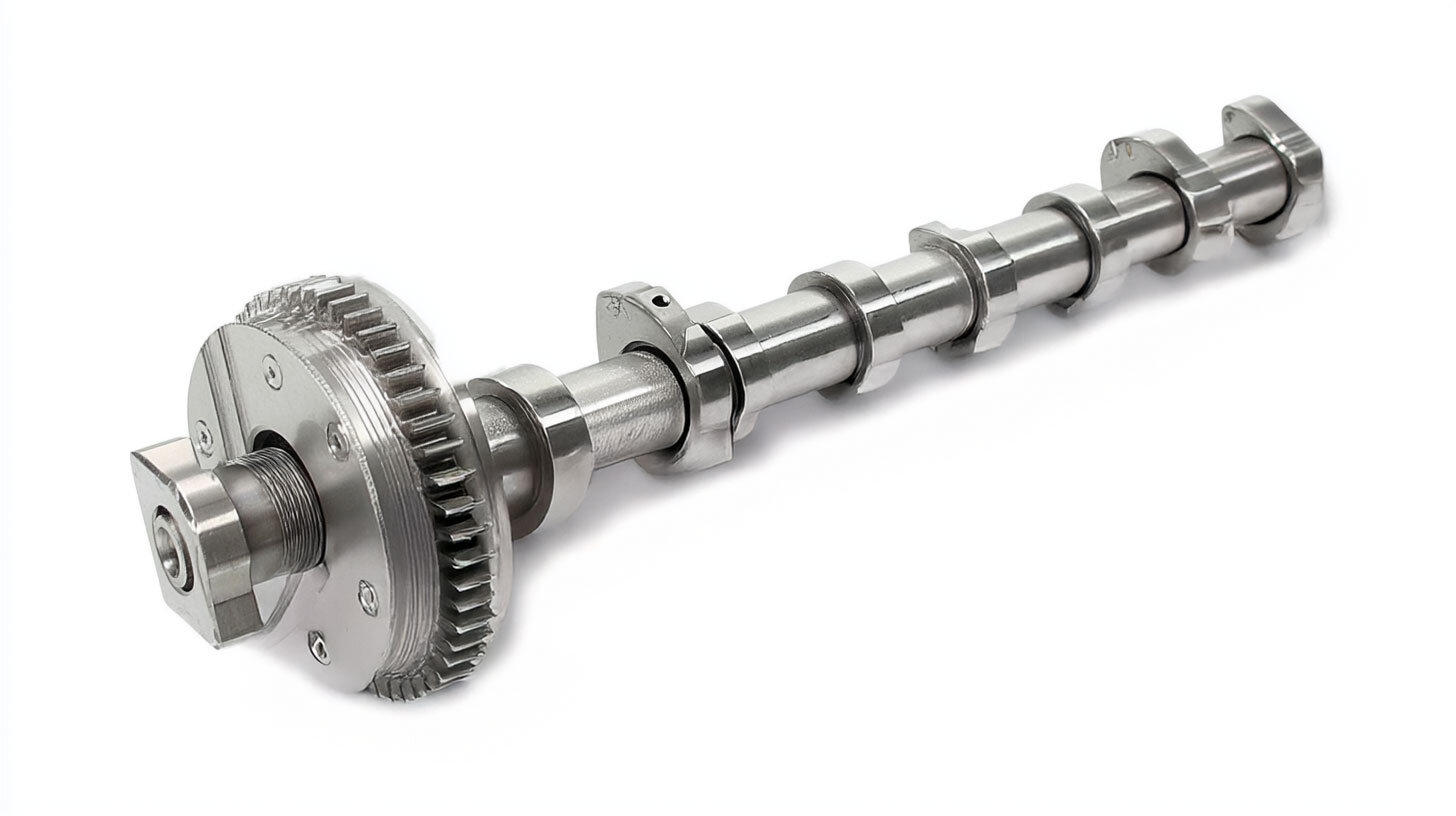

They’re the beating heart of any combustion engine: crankshafts and camshafts. While the crankshaft transforms the linear movement of the pistons into rotational motion, the camshaft controls the opening and closing of intake and exhaust valves.

The base material plays a key role in overall component quality. Common choices include tempered steels, nitriding steels, and cast materials – all known for their high fatigue strength, toughness, and good machinability.

- 42CrMo4 | AISI 4140

- 36CrNiMo4 | AISI 4340

- GJS-600