News on Die Forge, Heat Treatment & Industrial Furnaces at RUBIG

Get the latest insights into forging, heat treatment and plant engineering at RUBIG – follow our innovations and stay one step ahead!

RUBIG adds a powerful analysis tool to its visualization solution, making evaluations more intuitive and streamlining process control.

More precision, less wear: Why nitriding crankshafts and camshafts pays off twice.

CrN coatings protect components from wear, heat and friction – biocompatible, hard and ideal for industry and medical technology.

RUBIG Die Forge is now certified according to ISO 14001:2015 and ISO 45001:2018 – a clear commitment to sustainability, safety, and responsible operations at the Wels site.

A forging company lowered unit costs, improved flexibility, and reduced supplier dependency with in-house plasma nitriding. The MICROPULS® Everest system paid for itself in just 1.5 years.

Discover how RUBIG extends the service life of forging dies, reduces downtime, and significantly lowers unit costs through innovative nitriding processes – especially plasma nitriding – for more efficient and cost-effective production.

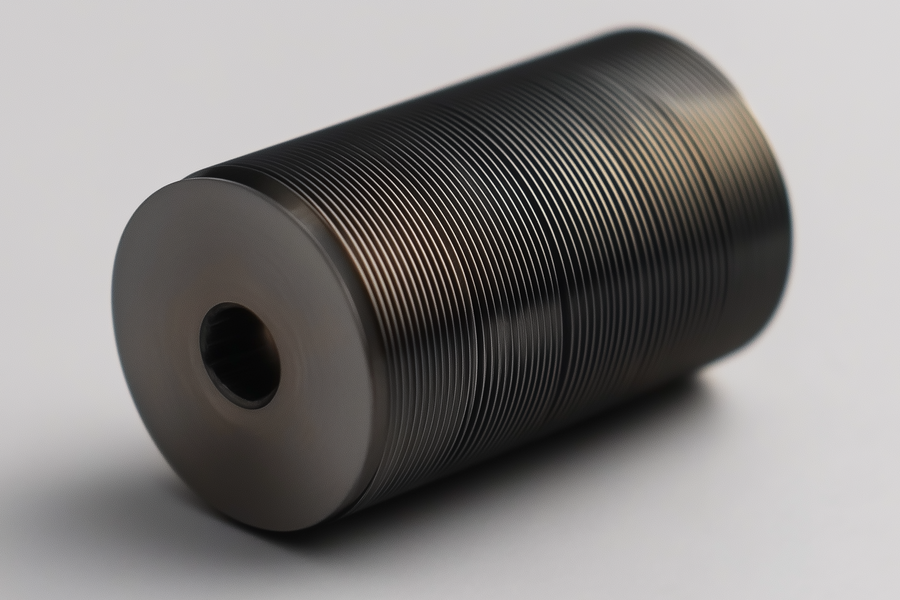

Thread rolling tools are subjected to extreme stresses, and every failure has financial implications. Plasma nitriding is an innovative surface hardening process that specifically reduces wear and significantly increases the service life of your tools. The process is precise, low-distortion, and environmentally friendly – making it ideal for demanding cold forming applications such as thread rolling.

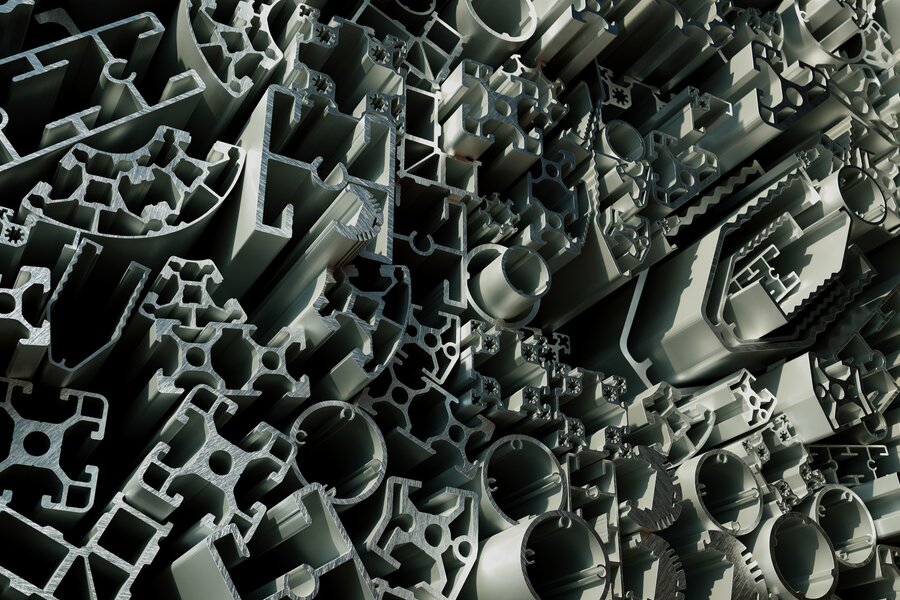

Aluminum extrusion presses aluminum alloys through tools to form complex, lightweight profiles. Thanks to their low density, corrosion resistance, and excellent formability, they are essential in the automotive, mechanical engineering, electrical engineering, and aerospace industries.

In January 2025, other important heat treatment processes were NADCAP-certified.

An interview with Sebastian Walchshofer, Head of the Automation and Software Department at RUBIG Industrial Furnances.

At the end of 2024, the RÜBIG Group will restructure its management: Bernd Rübig will assume joint leadership with Christian Dipolt,

Technology, man and machine are an unbeatable team! With the RUBIG visualization, these three success factors merge into an ultimate tool for your RUBIG system and transform effective processes into highly efficient processes.

Whether in the automotive, aerospace or mechanical engineering industries, they all benefit from the excellent tribological wear protection of WC/C-DLC coatings.

RUBIG enters new dimensions of surface treatment and offers innovative deep black coatings. With an L value of less than 30 in the L.A.b color space, the deep black coated components look as if they were absorbing the light.

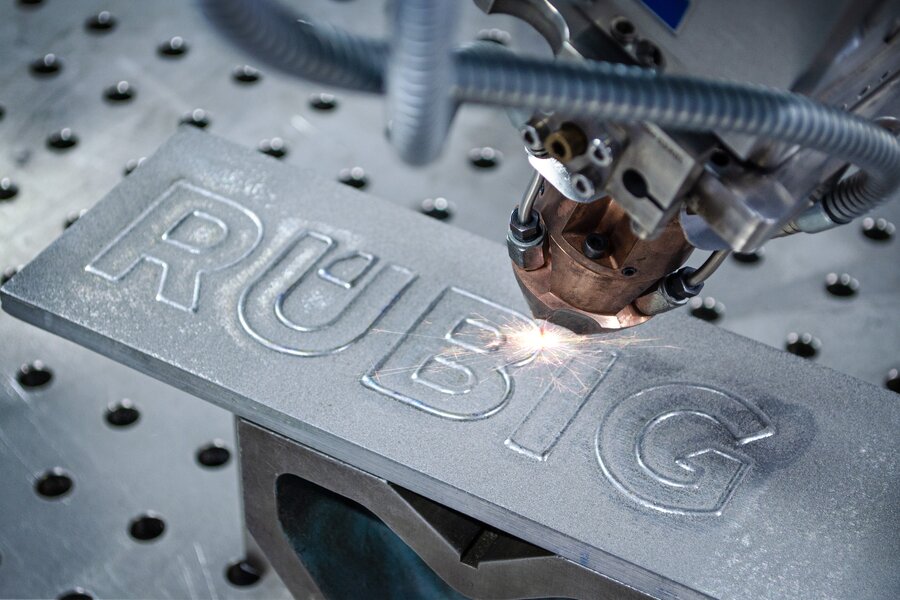

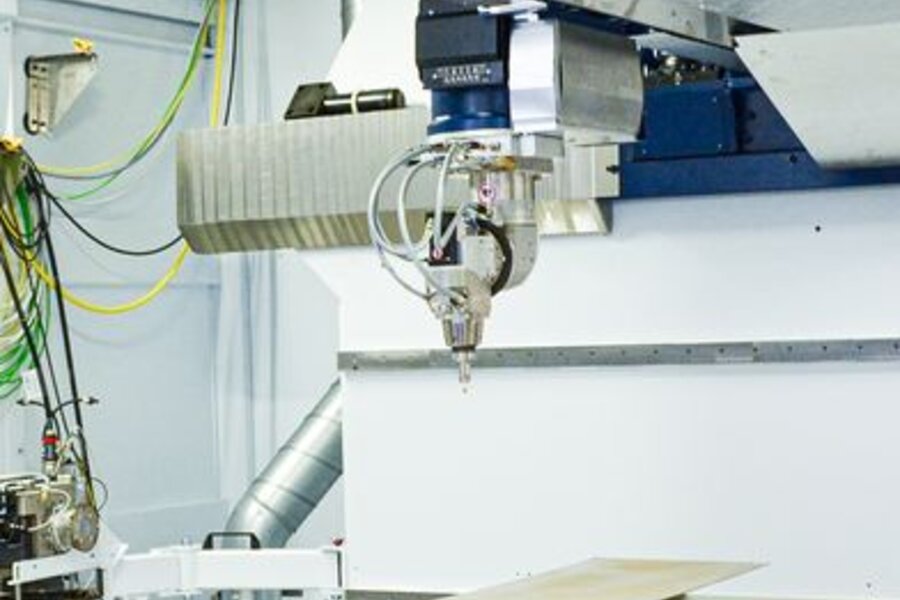

Cost and energy efficient: Laser deposition welding and laser hardening give your components the properties they need.

The extensive equipment of the materials laboratory for destructive material testing and metallography enables RUBIG to carry out test orders as well as material and failure analyses for customers quickly and reliably.

The RUBIG laser machining center is our most recent technology to improve wear resistance of tools and dies. This machine provides different metal working processes such as laser metal deposition (LMD) or laser hardening.

RUBIG's leading edge plasma nitriding technology is the key to reduce greenhouse gas emissions of the nitriding process and to increase the process economy at the same time

RUBIG has been offering specialized heat treatment technologies for safety relevant aerospace components for more than 15 years.

"Forging" is the collective name for all processes in which a metal workpiece is deformed by heat and pressure.

... the process engineer Graduated Engineer Andreas Gebeshuber.